Tungsten Carbide Nozzle Distribution

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 17:03

- Written by xiaobin

- Hits: 284

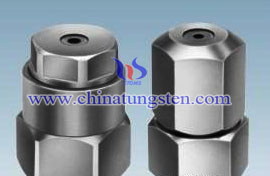

Either tungsten carbide hollow atomizing nozzle, solid atomizing nozzle or fan-shaped nozzle, their basic principle is similar, which spraying taper angle starts in end face and enlarge horizontal size by the increasing axial distance. It has a great amount of nozzle that widely used in combustion equipments for cleaning, coating and lubricating in order to achieve the uniform distribution. Therefore, we should arrange tungsten carbide nozzle appropriately in case of improper atomizing distribution.

Theoretically, it is reasonable that arrange the distance of nozzle in accordance with annular and string-like under the equal condition, which contains spraying taper angle, atomizing quality, the flow and volume flux (the sample fluid volume pass through the detected area in unit time). However, the practical application is different from the theoretical data.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Nozzle Reduce Abrasion Analysis IV

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 17:00

- Written by xiaobin

- Hits: 296

In addition, some experts expanding the length of nozzle to reduce the collision between grinding compound and inner wall of nozzle, which separates the core and the body and decreases the cost. There is a kind of structure design by American scholar, which is composed of penetrable stainless steel. What’s more, lubricant can pass through the media to adhere to inner wall of nozzle and build an oil slick layer after pressured. The oil slick layer will be supplemented by the pressure differential effect constantly after the erosion and shear of the grinding compound, which repairs the parts of erosion and shear wear and improves the concentration of beam of jet flow.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Nozzle Reduce Abrasion Analysis II

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 16:56

- Written by xiaobin

- Hits: 319

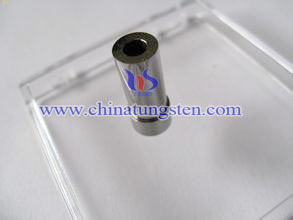

Secondly, compared with the acceleration of water flow, the acceleration of abrasive particles is delayed during the movements in nozzle, which depends on the shape of nozzle, the size and density of grinding compound, etc. Due to the turbulence inside nozzle, the grains of grind compound has higher horizontal speed and collides with inner wall of nozzle, which leads to erosion and abrasion.

Therefore, a reasonable shape of inner wall of nozzle plays a significant role in reducing abrasion. There are two normal methods for reducing abrasion. One is to get a small aspect ratio in order to ensure that the entrance before the most badly wore area. And the other is contrary, which is to get a large aspect ratio to ensure that the entrance after the most badly wore area.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Nozzle Reduce Abrasion Analysis III

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 16:58

- Written by xiaobin

- Hits: 294

At the present, the most widely used aspect ratio is 2:5. The experts design some unique structure nozzle to reduce the abrasion, such as tungsten carbide streamline nozzle with an arc entrance, tungsten carbide arc nozzle and tungsten carbide equal transmission nozzle. However, their processing is complicated and cost too much. A new style tungsten carbide nozzle, which take advantage of a step with angle to gather the most of grinding compound in center, which slow it down and reduce the abrasion in the area.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Porphyry tungsten Ore Deposit Occurrence in China

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 14:49

- Written by xinyi

- Hits: 434

Porphyry tungsten ore deposit occurrence in China

Lianhuashan mine in South China represents a new type of tungsten ore which can be described as a porphyry tungsten deposit. It is associated with a quartz porphyry stock of Yenshanian age (about 70–135 m. y.). The ore occurs in zone surrounding the contact of the quartz porphyry with Jurassic sandstone and extends into both rock bodies. The ore occurs either as the matrix of breccia or in the form of a very fine network of cross cutting veinlets. The major tungsten minerals are wolframite and scheelite associated with sulfide minerals of Mo, Fe, Cu, Pb and cassiterite. The minerals are fine-grained. There is zoned alteration in the wall rocks. From the center of the quartz porphyry toward the wall rocks one finds: potassic alteration, silicification-sericitization, and chloritization. All these features are similar to those of porphyry copper mineralization.

Fluid inclusion studies show three types of inclusion: liquid-rich (Type I), gas-rich (Type II), and polyphase with daughter minerals (Type III) fluid inclusions. The homogenization temperatures of Type I range from 210° to 380°C, with a salinity of 2–15 wt.% NaCl equiv., those of Type II from 270° to 420°C, and those of Type III from 240° to 400°C with a salinity of 31–33 wt.% NaCl equiv. The closely associated group of gas-rich and daughter mineral-bearing fluid inclusions homogenized at almost the same temperatures. Such results indicate boiling of oreforming fluids. These fluid inclusion data indicate that low salinity (Type I) and high salinity fluids (Type III) responsible for porpb yry copper deposits are the same as those for porphyry tungsten ore deposits.

These observations suggest that the Lianhuashan tungsten ore deposit is a porphyry tungsten deposit and was formed by hydrothermal fluids similar to those responsible for the well-known porphyry copper deposits.

sales@chinatungsten.com

sales@chinatungsten.com