Tungsten Ore Uses

- Details

- Category: Tungsten Information

- Published on Monday, 24 August 2015 15:02

- Written by xinyi

- Hits: 283

Uses:

Tungsten contained in the tungsten ore used in many areas.

Tungsten is mixed with carbon to make a very strong, very resistant material called tungsten carbide. Tungsten carbide is used to make cutting tools and wear-resistant tools for metalworking, drilling for oil and gas, mining, and construction. These applications account for more than 60% of the tungsten consumed in the US each year.

Because it has such a very high melting point and low vapor pressure, tungsten is used in high temperature situations. For instance, the filaments in light bulbs are made of tungsten. It is used in other applications in electronics as well.

When added to steel, tungsten increases its strength. It is alloyed (mixed with) other metals to make "superalloys" which have special physical properties of high strength and heat resistance. Some of the applications for such superalloys are in turbine engines for jet aircraft and energy generation.

Other alloys bearing tungsten are used for armaments, heat sinks, radiation shielding, weights and counterweights, wear-resistant parts and coatings.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

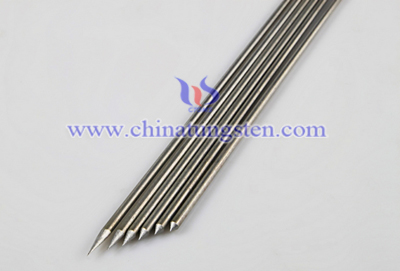

Sharpened Tungsten Needle

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 17:53

- Written by Yahong

- Hits: 284

The tungsten needle with the tip that sharpened is mainly used for the instrument probe using. Such as, digital four probe tester, the device is multi-purpose measuring equipment using four point probe measurement principle.

The sharpened tungsten needle is a non radioactive material, whose electron emission ability is higher than thorium tungsten material, and its arcing voltage is low, arcing is stable. The positive polarity, the allowable current density is higher than thorium tungsten of 5%-8%; AC allowable current density is high, and its service life is long, which is suitable for DC or AC electric welding, what’s more, if the using time is the same with thorium tungsten, its service life is longer. Usually, it is used for the welding of carbon steel, stainless steel, titanium and other metals.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Bulls-eye Baseball Tungsten Dart Rule

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 17:25

- Written by yingying

- Hits: 311

Bulls-eye Baseball tungsten dart rule is a difficult yet fun game that may be played by as many players or teams as wish to play. It is the same game as regular Baseball with a twist to make it more challenging.

The Object: The object is simple: score the most amount of runs each inning, the highest score at the end of the game wins.

The Scoring: The numbers 1 through 9 are written in ascending order on the left side of the scoreboard. All players names are written in batting order across the top (batting order may be determined any way, usually one tungsten dart each at bulls-eye with the closest throwing first and the furthest last). A grid may be drawn around the numbers and the names for easier reading.

The Play: Each player in order throws three tungsten darts at the number of the current inning but must hit a bulls-eye each inning before any runs may be scored that inning. If no bulls-eye is hit, the score for the inning is zero. The target is 1's in the first inning, 2's in the second, etc. Each number only counts in that actual inning. For example, if a 4 is hit in the first inning, it does not count. The thin outer "double" ring counts as two runs, the thin inner "triple" ring counts as three runs with the other sections of that number counting as one run. If more than one bulls-eye is hit the score is multiplied by the number of bulls-eye's hit. Therefore, the highest attainable score in any one inning is twelve (Double-Bulls-eye, Triple-x, Triple-x {where x is the number of the inning} would score 6 for the two triples time 2 bulls-eyes).

The number of runs scored is not multiplied by the inning number. For example, in the second inning, a bulls-eye and two single 2's are hit; that players score would be two for that inning.

Usually a running total is kept with the current inning's score being added to the current total. This way, players can see how far ahead or behind they are and save a lot of time not having to add all nine innings at the end of the game.

If there is a tie at the end of the ninth inning, extra innings are played with bulls-eyes as the target. Extra innings continue until after all players have thrown for that inning and no tie exists.

Strategy: Try to score a lot of runs.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Processing of Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 17:47

- Written by Yahong

- Hits: 316

The processing of tungsten electrode is adopting the method of powder metallurgy, in which the cerium tungsten electrode processing is similar to cerium tungsten electrode. Following is three procedures to make tungsten cerium electrodes.

First of all, mix cerium nitrate aqueous solution with a solid of APT or WO3 well-distributed by the methods of spaying and coating. Then heat it to the state of tungsten cerium coated powder.

Secondly, reduce tungsten cerium coated powder in twice to tungsten cerium powder. After reduction, make tungsten cerium powder into tungsten cerium billet by pressing and sintering.

Finally, press and forge tungsten cerium billets into tungsten cerium electrodes.

Tungsten is an important material for many products and is also one of the essential industrial process welding equipment.

There are many different kinds of tungsten electrode, but, thorium tungsten electrode and cerium tungsten electrode are the ones which are the most used on the domestic market. Why the phenomenon occurs is that people are insufficient in the understanding of thorium reflective damage, guidance in this point should be strengthened in the sales process.

Tungsten electrode, as one of the industrial welding equipment, which is actually acting as both welding materials and electrician electrical, this kind of welding materials without burning has a loss in welding.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Flotation of Tungsten Ore

- Details

- Category: Tungsten Information

- Published on Friday, 21 August 2015 17:22

- Written by xinyi

- Hits: 288

The flotation of tungsten ore is conducted at a pulp pH of 9.0-10.5. Soda ash, caustic soda, or sodium silicate may be used for alkalinity control.

The other modifying agents required will depend on the gangue minerals to be depressed. Quebracho or tannin is used to depress the calcite, but an excess will also depress tungsten minerals. Sodium dichromate acidified with sulfuric acid has also been reported as a calcite depressant and copper silicate (sodium silicate and copper sulfate) has been reported as a depressant for fluorite. Figure 8 shows a tungsten flotation flowsheet. The most commonly used tungsten collectors are crude oleid acids or tall oils, or the more refined fatty acids or soaps.

Most tungsten flotation concentrates and some table concentrates are not of sufficiently high grade to meet the exacting specifications of the market. The principal diluents are phosphates and carbonates, which are difficult to depress sufficiently in flotation. The removal of these minerals is most frequently accomplished by leaching the concentrates with hydrochloric acid. Because of the relatively simple equipment required, the trend has been toward leaching at the flotation plant. However, a number of custom leaching plants are equipped to treat flotation concentrates from the smaller concentrators.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com