Industry Applications of Tungsten Polymer

- Details

- Category: Tungsten Information

- Published on Friday, 17 July 2015 14:05

- Written by wenjing

- Hits: 376

tungsten polymer is composed of tungsten powder and one of a number of standard plastic base resins, which are selected according to the application. These base resin systems include polysulfones (PSU), co-polyamides, polyamides (PA), polymethylpentenes (PMP), polyurethanes (TPU), acryloynitrile butadiene styrene (ABS), polyethylenes (PE) and polyetheretherketones (PEEK). It has a high molecular polymer composited material having a density up to 11 g/cc (equivalent to lead). It is composed of the following components by weight ratio: a high molecular polymer 20-100, tungsten powder 950-1000, tungsten fiber 0-50, a coupling agent 0.5-5 and other aids 0.5-10.

Tungsten polymer has been found many applications in industries, including:

- X-ray devices in manufacturing industries and medical x-ray machines;

- Nuclear and medical industries, it is used as radiation shielding;

- Radiation shielding and radiation-protective equipment;

- Gamma ray shielding material and substitute for lead fiber mat in nuclear reactor piping systems;

- It is also used in weight and balance applications as a counterweight for applications like motors, ballasts and more;

- Used as a sound proofing material in aviation headphones;

- Acts as a damper to reduce shock due to vibration in the automotive industry.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

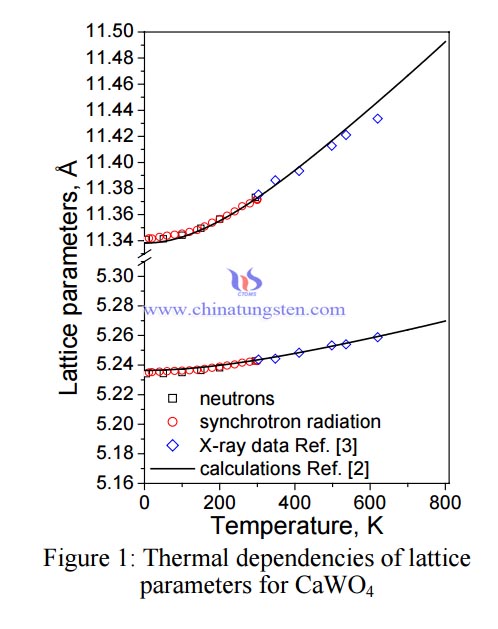

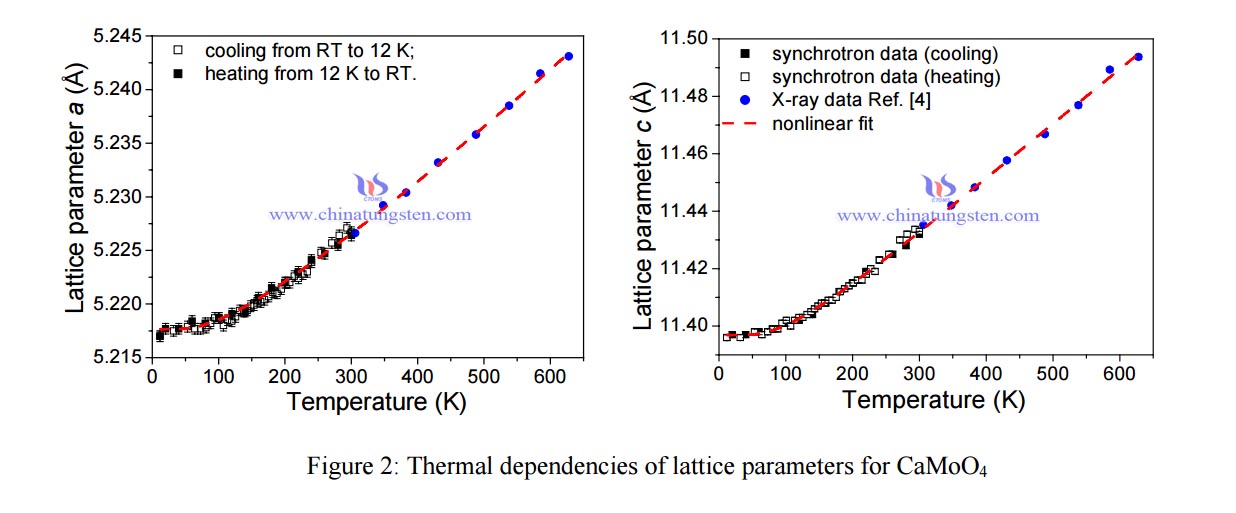

Low-temperature Structural Properties of Calcium Tungstate and Calcium Molybdate-III

- Details

- Category: Tungsten Information

- Published on Thursday, 16 July 2015 18:04

- Written by xinyi

- Hits: 324

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Low-temperature Structural Properties of Calcium Tungstate and Calcium Molybdate-II

- Details

- Category: Tungsten Information

- Published on Thursday, 16 July 2015 17:53

- Written by xinyi

- Hits: 355

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Defect Types of Tungsten Contacts- I

- Details

- Category: Tungsten Information

- Published on Thursday, 16 July 2015 18:02

- Written by Yahong

- Hits: 333

Defect types of tungsten contacts described as follows:

1. Porous holes, pores

This defect type is common in powder metallurgy to prepare tungsten contacts. This may be because:

Uneven particle size of tungsten powder;

The gas content of tungsten powder is relatively large;

Insufficient pressure when mixing powder;

Insufficient infiltration, when you are sintering the porous tungsten skeleton.

2. Unevenly distributed organization

Reason: Because of the existence of added element, it makes the added element or poor oxide in grain boundaries aggregated.

3. Inclusions

Under normal circumstances, the presence of inclusions in the tungsten contacts may be due to: non-metallic inclusions mixed in them and other foreign metal inclusions mixed with.

4. Bubbles

Because there are small holes in tungsten ingot itself, and the phenomenon of inner oxide will appear when pressing, crushed holes will expand to form bubbles.

5. Delaminating cracks

Because tungsten ingot itself has already gathered micro cracks, during the oxidation process, because stress makes delaminating of the cracks.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Low-temperature Structural Properties of Calcium Tungstate and Calcium Molybdate-I

- Details

- Category: Tungsten Information

- Published on Thursday, 16 July 2015 17:36

- Written by xinyi

- Hits: 324

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com