Tungsten Ores World Resources

- Details

- Category: Tungsten Information

- Published on Tuesday, 21 July 2015 16:34

- Written by xinyi

- Hits: 361

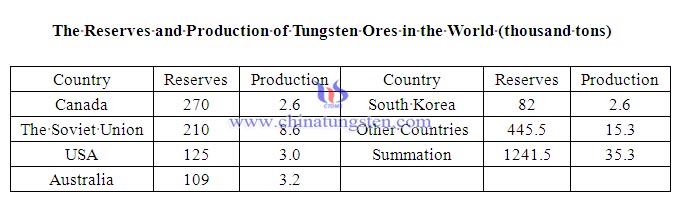

About 20 species of tungsten minerals are known, of which wolframite [(Fe, Mn) WO3] and scheelite (CaWO4) have industrial value.Tungsten ore grade mined in 70s, more between 0.2 ~ 0.5% WO3, can get containing tungsten trioxide 60 to 70 percent or higher grade tungsten concentrates after dressing. China's tungsten ore reserves account for more than half the world's total reserves, mainly in Hunan, Jiangxi, Guangdong and Fujian provinces. In 1979, the world's major tungsten producing countries (except China) of tungsten ore reserves and production in the following table:

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Properties Requirements of Tungsten Copper Points

- Details

- Category: Tungsten Information

- Published on Tuesday, 21 July 2015 16:01

- Written by Yahong

- Hits: 370

Tungsten copper points, which can be applied to control the current of the switch, and mainly play a role in relays, contact switch, breakers, magnetic motors and other parts, also namely tungsten copper electrical points. Points properties will directly have an effect on the work of the entire electrical system, particularly communication system, modern automatic control system and other large power system, the system will work in a mess or even can’t run if one or more points in them, whose properties derogate, so, the work properties of tungsten copper points should be improved.

Properties requirements of tungsten copper points can be seen as below:

1. Require the points owning good electrical conductivity and nice thermal conductivity to reduce heat loss and the tungsten oxide on the surface of points;

2.Require points material having high boiling point, high melting points, high melting heat and evaporation heat to reduce contact wear and the occurrence of welding of the points under the arc / spark action;

3. Require the point having stable chemical properties, stable contact resistance, and small change of contact resistance when it being polluted by the environment;

4. Require the points possessing appropriate elasticity and hardness, the contact area would be small when the hardness is too large, due to bounce between the points, the wear will increase when the flexibility is greater;

5. Own the properties of easy machining and welding;

6. The price is lower.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Factors on Tungsten Copper Contacts - Structure Size and Manufacturing Processes

- Details

- Category: Tungsten Information

- Published on Tuesday, 21 July 2015 15:44

- Written by Yahong

- Hits: 329

Factors on tungsten copper contacts can be seen from the following main points:

1. The structure size. In theory, if the structure size of tungsten copper contacts is larger, then its anti-arc ablation performance will be stronger, because its use of energy more dispersed. In actual use, because the limit size of electrical switch structure, its size can not do much. In recent years, someone has developed plug-in contacts, hollow contacts, not only accelerates the speed of heat dissipation of contact materials, but contacts can still maintain good contact state after the ablation.

2. The manufacturing processes. Now manufactures in China are commonly applying infiltration method (mixing powder, pressing, sintering) to prepare tungsten copper contacts. What is different is that whether there is the use of sintering tungsten skeleton infiltration process. Compared with the performance of tungsten copper contacts, the ones used the process for the preparation is more ideal than the other ones without using it. In recent years, foreign countries have adopted more advanced preparation technology to improve the life of the contacts, such as, arc melting, sintering rolling process, fiber-reinforced method and so on, but China for the use of these new processes are still in the laboratory stage.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Factors on Tungsten Copper Contacts - Tungsten Powder Particle Size, Applications Occasions, Current Properties, the Breaking Speed of Contact and Early Pressure

- Details

- Category: Tungsten Information

- Published on Tuesday, 21 July 2015 15:46

- Written by Yahong

- Hits: 298

There are many factors on tungsten copper contacts, among which the main factors are structure size of the contacts, the manufacturing process, the particle size of tungsten powder, applications occasions, current properties and the breaking speed of contact and early pressure and so on. " Factors on Tungsten Copper Contacts - Structure Size and Manufacturing Process" which focuses on the factors of structure size and manufacturing process, and this article will introduce the factors of tungsten powder particle size, applications occasions, current properties and the breaking speed of contact and early pressure:

3. The tungsten powder particle size. Studies have shown that, whether it is with a thicker tungsten powder or thinner tungsten powder to prepare a contact material, their anti-arc erosion performance is not very good, but if prepare the contact by mixing the coarse powder and fine powder at a certain percentage, then the performance of tungsten copper contacts are relatively better. Note items: if the components of the contact material are different, then their mixing proportions are also different.

4. Applications occasions. The experimental results show that for different applications occasions, different components of the contact have its corresponding optimal application occasions. For example, in air or a vacuum switch, tungsten (90) / copper (10) its performance against arc erosion is the best.

5. Current properties. Studies have shown that if the properties of the current are different, and then its on-off process will produce different transient properties, however, after selecting the contact, its value is constant.

6. The breaking speed of contact and early pressure. Arcing time is determined by breaking speed especially early opening rate; arcing time can be shortened by increasing the early speed to achieve it, so that the possibility of contact ablation reduced. If the early pressure is increased, the mechanical vibration of the contact can be reduced, so that the arc erosion and mechanical wear is reduced.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Contacts Prepared by Injection Molding

- Details

- Category: Tungsten Information

- Published on Tuesday, 21 July 2015 15:42

- Written by Yahong

- Hits: 317

Tungsten copper alloy having a high density, high strength, high temperature resistance, microstructure uniformity, resistance to arc erosion and other characteristics, and its electrical conductivity and thermal conductivity are good. It is widely used, mainly in microelectronics materials, EDM electrode, military high temperature resistance materials, high-voltage switch with electrical alloys, as parts and components are widely used in aerospace, power electronics, machinery, metallurgy, sports equipment and other industries.

Tungsten copper contacts combined with excellent characteristics of the metal tungsten and copper. Among them, tungsten owns high melting point, high density; copper owns superior conductive and thermal performance.

The melting point of tungsten: 3410 ℃; the melting point of copper: 1080 ℃;

Tungsten density: 19.34g / cm3; copper density: 8.89 g / cm3;

Tungsten copper alloy composition range: WCu7 ~ WCu50.

Injection molding is relatively common method of making tungsten copper alloy. Tungsten copper contacts prepared by injection molding method: mixing copper tungsten powder with uniform particle size of 1-5 microns and nickel powder or iron powder with tungsten powder with a particle size of 0.5-2 micron and tungsten powder with a particle size of 5 -15 microns, and then entering into the 25% -30% of the organic bonding agents (such as paraffin or polymethylmethaerylate) for injection molding, then using steam cleaning and irradiation method to remove the binder, sintering in hydrogen, finally to obtain tungsten copper alloy with high density.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com