TUNGSTEN MINING & BENEFICIATION

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 12:03

- Written by xinyi

- Hits: 375

Tungsten is usually mined underground. Scheelite and/or wolframite are frequently located in narrow veins which are slightly inclined and often widen with the depth. Open pit mines exist but are rare.

Tungsten mines are relatively small and rarely produce more than 2000t of ore per day. Mining methods for tungsten ore are not at all exceptional and usually are adapted to the geology of the ore deposit.

Most tungsten ores contain less than 1.5% WO3 and frequently only a few tenths of a percent. On the other hand, ore concentrates traded internationally require 65-75% WO3. Therefore, a very high amount of gangue material must be separated. This is why ore dressing plants are always located in close proximity to the mine to save transportation costs.

The ore is first crushed and milled to liberate the tungsten mineral crystals. Scheelite ore can be concentrated by gravimetric methods, often combined with froth flotation, whilst wolframite ore can be concentrated by gravity (spirals, cones, tables), sometimes in combination with magnetic separation.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Flat-top Button Shortcomings

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 18:49

- Written by xiaobin

- Hits: 321

It is obvious that flat-top tungsten carbide button would abrasive easily in some rock formation. According to incomplete statistics, almost flat-top tungsten carbide buttons are wasted when their 75% heights are not using. And the velocity of its plate enlarging is faster than the corrosion of the top. In addition, the longer diameter of the plat, which depresses the pressure between buttons and rock surface. Especially when impact load is insufficient, velocity of drilling would be influenced. So the efficiency of impact energy will be lower. Finally, due to the bottom of flat-top is flat, air inside the hole is hard to release to come into cushion when it has been set. So the pillar is unstable fixed.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Structure of Tungsten Collimator Kit

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 18:39

- Written by wenjing

- Hits: 419

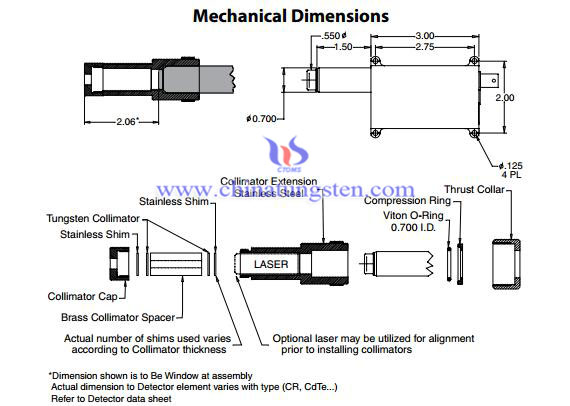

In order to accommodate applications where the X-ray flux is too high for both the detector and the electronics that process the X-ray spectrum, a “Collimator Kit” has been developed to collimate the primary X-ray beam. This system is comprised of standard 1.5 inch extender box which slides inside collimator housing.

The collimator housing can accommodate up to two tungsten collimator disks that are placed inside a bayonet holder in front of the detector. All tungsten disks are made of alloy HD17 (90% W, 6% Ni, 4% Cu). All Tungsten disks and spacers have a diameter of 0.625 inches. This Tungsten (W) Spacer /Collimator is 36 mm thick with a 300 µm hole. It is designed to stop and collimate x-rays greater than 100 keV produced from high energy tubes.

The picture shows the structure of tungsten collimator kit:

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cemented Carbide Mining Button Grades

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 18:41

- Written by xiaobin

- Hits: 319

Cemented Carbide Mining Button Grades

|

Grade |

Performance & application recommended |

Density |

Hardness |

TRS |

|

g/cm3 |

HRA |

MPa |

||

|

YG4C |

Mainly used as small buttons for percussion bits to cut soft and medium hard formation. |

15.1 |

90.0 |

1800 |

|

YG6 |

For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. |

14.9 |

90.0 |

2100 |

|

YG8 |

For coring crowns, electric coal drill bits, coal cutting picks, oil cone bits and scraping knife bits, used in geological prospecting, coal mining and oil well boring. |

14.7 |

89.5 |

2400 |

|

YK05 |

Mostly used as the buttons of small and medium sized percussion bits and as the inserts of rotary prospecting bits to cut soft and medium hard formations. |

14.95 |

90.5 |

2500 |

|

YG8C |

Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard formations. |

14.7 |

88.5 |

2450 |

|

YK15 YG9C |

Suitable to strips, conical buttons for rotary percussion-resistant, geological prospection buttons, cut soft and medium hard formations. |

14.7 |

87.8 |

2450 |

|

YG20 YG10C |

Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and hard formations. |

14.4 |

87.0 |

2550 |

|

YK25 |

Primarily for the buttons and inserts of rotary percussion bits to cut medium-hard and very hard formations. |

14.5 |

87.5 |

2600 |

|

YG11C |

Largely for the inserts and buttons of percussion bits and tricone bits to cut medium-hard, hard, and very hard formations. |

14.4 |

87.0 |

2600 |

|

YK40 YG13C |

Primarily for the buttons of tricone bits and inserts of rotary percussion bits to cut hard and very hard formations. |

14.2 |

86.5 |

2650 |

|

YG15C |

For oil cone drill bits, for medium soft and medium-hard rocks. |

14.0 |

86.5 |

2700 |

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy for Medical Equipment

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 18:34

- Written by wenjing

- Hits: 312

Because tungsten alloy for X-ray attenuation ability is used for all kinds of radioactive source shielding components or container of a kind of ideal material. In addition, tungsten alloy is high density and environmental friendly. Tungsten alloy is usually used in the medical anti-radiation shielding materials and gamma knife.

Medical tungsten alloy radiation shielding material series, tungsten alloy grating blade, tungsten alloy protective tank -- for medical radiation shielding wall. Tungsten alloy can be produced as needle radiation shielding for medical radioactive liquid shielding. Tungsten alloy memory, cans, boxes and other containers used to store radioactive matter, collimator, for medical linear accelerator and nuclear technology applications in tungsten alloy series test container system collimator, Co60 radiation shielding.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com