Tungsten Contacts Corrosion

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 16:00

- Written by Yahong

- Hits: 345

The main factors affecting the corrosion rate of tungsten contacts corrosion are: impurities of air, humidity and metal surfaces state. If the humidity in the air is greater, the condensation of the water film on the metal surface will be thicker, so the resistance of the water film will be smaller, the corrosion will faster.

The chemical reaction formula of tungsten contacts corrosion process is as follows

W + O2 = W - 4e + O2 = WO2

2WO2 + H2O – e = W2O5 + 2H

W2O5 + H2O - e = 2WO3 + 2H

WO3 + H2O = H2WO4(black gum)

H2WO4 – H2O = WO3(dehydration → tan dura)

As can be seen from the above formula, the nature of the electrochemical corrosion, which is the process of the metal atom loses electrons and be oxidized.

Electrochemical corrosion referring to the process that metal and the electrolyte have an electrochemical reaction so that the metal is destroyed.

Metal electrochemical corrosion conditions:

1. There is potential difference between metals

2. Reaction takes place in the electrolytic liquid, etc.

Tungsten contacts will corrode in humid (usually, it occurs when air humidity is greater than 60%), and is called atmospheric corrosion, which is a kind of electrochemical corrosion. Atmospheric corrosion occurs on the electrolytic film layer of the metal (dissolved a variety of salts and corrosive gas impurities), the formation of the film is due to water vapor in the atmosphere condensed or adsorbed on the metal surface.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Analysis of Tungsten Points Surface Film from its Electrode Potential

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 15:57

- Written by Yahong

- Hits: 351

Tungsten (W) is the main raw materials of tungsten points, that is to say, analysis of tungsten points’ surface film from its electrode potential is similar to the analysis of tungsten.

Each species owns the characteristic of standard electrode potential, which is a kind of equilibrium electrode potential.

The standard electrode potential at 25 ℃

|

Metal |

Ion |

Electrode potential (V) |

|

W |

W |

-0.2 |

|

Ni |

Ni2+ |

-0.23 |

|

Ag |

Ag+ |

+0.799 |

|

Cu |

Cu2+ |

+0.34 |

|

Pb |

Pb2+ |

-0.126 |

|

Fe |

Fe2+ |

-0.44 |

Standard electrode potential---put a matter in some kind of solution, which contains matter’s ions, the potential difference between the matter and the standard hydrogen electrode is the very standard electrode potential when ion concentration is 1g / L. The metal will be more active when negative value of standard electrode potential is bigger; but it will be less active when standard electrode positive value is larger.

What can be drawn from the table is that the potential difference between W and Cu is the biggest, which is 0.54V. The points’ material electrochemical corrosion is prone to appear in a high temperature, high humidity environment. Nevertheless the corrosion between W - Ni is slighter than W - Cu’s, W – Ag’s. Electrochemical corrosion is not prone to occur since the potential difference of W - Ni is only 0.03V, whose. Therefore, adding a right amount of Ni can improve oxidation resistance property of tungsten points, which will reduce the formation of its surface film.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

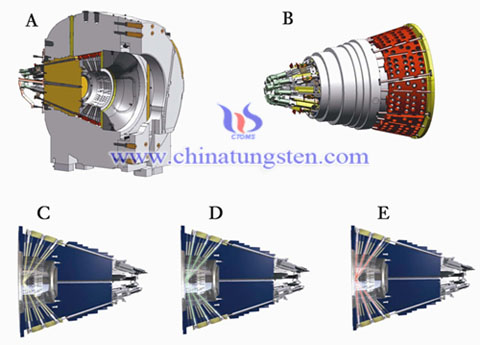

Tungsten Collimator Rings in Gamma Knife

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 15:02

- Written by wenjing

- Hits: 360

In a gamma knife machine, a total of 192 60Co sources are arranged in a cylindrical configuration in five concentric tungsten collimator rings. The radiation cavity has been increased by more than 300% compared to previous models. However, due to an improved collimation system (120 mm tungsten collimator rings), the average distance from source to focus is very close to previous models. This results in similar output for the prior 18mm and new 16 mm administrations. This differs substantially from the previous hemispherical arrangements and results in different source to focus distances for each ring varying from 374 to 433 mm. The primary and secondary collimators have been replaced by a single large 120 mm thick tungsten collimator rings.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Electrode Potential Analysis on Tungsten Contacts Surface Film

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 15:56

- Written by Yahong

- Hits: 384

The main content of tungsten contacts is tungsten (W), i.e. electrode potential analysis on tungsten contacts surface film can be available from tungsten analysis.

Standard electrode potential is a kind of equilibrium electrode potential, and each substance has this feature.

Standard electrode potential refers to: placing a substance in a solution containing its ions, if the ion concentration in the solution is 1g / L, the potential difference between the substance and standard hydrogen electrode is standard electrode potential. If negative value of standard electrode potential is bigger, the metal will be more active; If the positive value is larger, the metal will be less lively.

At the temperature of 25 ℃, the standard electrode potential of several metals table

|

Metal |

Ion |

Electrode potential (V) |

|

W |

W |

-0.2 |

|

Ni |

Ni2+ |

-0.23 |

|

Cu |

Cu2+ |

+0.34 |

|

Ag |

Ag+ |

+0.799 |

|

Fe |

Fe2+ |

-0.44 |

|

Pb |

Pb2+ |

-0.126 |

From the above table, which shows that the potential difference between the electrode W and Cu is 0.54V, in a condition of high temperatures and high humidity, the contacts material’s electrochemical corrosion is prone to appear. Whereas the phenomenon on W and Ni corrosion is more slight than W and Cu, W and Ag, because the potential difference between the electrodes W and Ni is only 0.03V, whose electrochemical corrosion is not easy to take place. So, the right amount of Ni can be added to tungsten contacts to increase its oxidation resistance capacity, that is to say, reducing the likelihood of its surface film formation.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Applications of Tungsten Polymer for Industry

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 14:57

- Written by wenjing

- Hits: 314

As its special high density of 11.34 g/cm3 min., tungsten polymer has a perfect radiation shielding performance comparable to lead for anti-radiation shielding, and it is much healthier. Besides, tungsten polymer is very easy to be cut or held with household scissors and so much formable into shapes with various curved surfaces.

Tungsten polymer can be used widely in industry, such as the radiation shielding for radiation detectors , and nuclear industry radiation protection. Tungsten polymer for shielding X-ray and gamma radiation including a full body apron and a thyroid guard are the first commercially available, it can greatly enhance both the material properties and the shielding efficiency.

Applications of Tungsten Polymer for Industry:

Nuclear logging radiation shielding

Welding inspection radiation shielding

Container inspection radiation shielding

Nuclear submarine radiation protector

Nuclear reactor radiation protector

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com