Tungsten Ore Application

- Details

- Category: Tungsten Information

- Published on Thursday, 30 July 2015 11:51

- Written by xinyi

- Hits: 322

After by the beneficiation process of tungsten, tungsten was silver, high hardness, high melting point, room temperature, from air attack; can be used to manufacture filament and high-speed cutting steel, hard tooling, but also for optical instruments, chemical instrumentation. Tungsten because of its high temperature can maintain most of the high hardness and wear resistance is also used in the production of special steel. WC-based cemented carbide can be used for both cutting tools, mining machinees, and drawing modules. Contact material and the high proportion of alloy used in the manufacture of the gyroscope rotor, aircraft, control the rudder balance weight, radioactive isotopes and radiation shielding material basket, electric vacuum lighting materials. Tungsten ore and tungsten compounds are widely used in metallurgical materials tungsten raw materials.

Tungsten ore in particular extensive use of many and can produce and refine a variety of different products. For example, pure tungsten, tungsten alloy, tungsten heavy alloy, tungsten carbide, tungsten copper, tungsten powder, tungsten carbide powder, silicon carbide, tungsten electrode.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Know Which Type of Tungsten Dart Tip You Need?

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 17:58

- Written by yingying

- Hits: 356

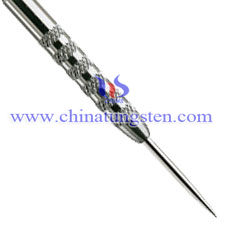

Steel tip darts are mostly used with bristle dartboards. Steel tip darts have a very sharp steel point to stick in the fiber of a bristle board. They can be complex with as many as five completely separate removable parts, and can be tuned for performance. Many models are available in different weights. Steel tip darts can be made of brass, nickel - silver, tungsten, and copper. However, most dart players will choose steel tip of tungsten, because tungsten is a metal with high-density and so durable. There are two options about steel tip of tungsten darts. One is fixed-point tip, the other is moveable-point tip. The fixed-point tip, as the name implies, it does not move, and this is the most common type. The moveable-point tip can move, it can help decrease the chance for a bounce-out. If you are always throwing on real hard boards, or older type boards that don't have all the nice features, moveable points may be for you.

Soft tip darts are mostly used with electronic dartboards. Soft tip darts have a flexible, plastic tip on the end to easily lodge into the holes on electronic dartboards. Usually lighter than steel tip darts, soft tip darts can be weighted differently, and be as complex. Soft tip darts can be made of plastic, brass, nickel - silver, tungsten, and copper. Most professional players would choose soft tip of tungsten darts.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button New Sintering Technology

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 17:50

- Written by xiaobin

- Hits: 327

This new technology not only overcoming traditional vacuum sintering weakness that it will leave a amount of internal defects, which reduces tungsten carbide performance, but also decreases machinery expenses and improves the efficiency. It can remove the gap inside carbide button extremely, and picks out the raw grain to refine it. It is significant for improving the density of tungsten carbide button, and showing good performance. Currently, many manufactures are start using this sintering technology to provide a great quantity of tungsten carbide buttons.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button Gradient Structure Optimization

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 17:51

- Written by xiaobin

- Hits: 332

The top layer of gradient cemented carbide contains WC much to resist abrasion. The middle layer contains an amount of Co, so it has good toughness. This structure is beneficial for drilling, which has larger impact loads and longer working life. For instance, using φ45mm drill bit with DP55 cone button in limestone tunnel drilling, the average working life of gradient structure is 3121m at 1.96m/min compare with the ordinary 1000m at 1.48m/min. Many researchers overseas proves that the amount of carbon practical needs 0.1% -0.4% lower than theoretical value, and an appropriate increase in carburizing temperature conducive to migrate to the liquid Co sintered body inside. In addition, the different size of the sintered body should choose different respective carburizing time.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button for Drilling

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 17:48

- Written by xiaobin

- Hits: 311

Drilling means that relevant tungsten carbide button should be tough and hard enough. According to the different types of rock formation and hardness, they can be divided into different grades, such as YG6, YG8, YG8C, YG11C, YG13C, YG15, etc. If the rock formation is pretty hard and the impact is huge, we should choose the carbides contain Co more and raw grains alloy. On the contrary, we should choose the little one.

Tungsten carbide button are bearing strength of pulling, bending, pressing, twisting and some cyclic stress when it is working. So they have to bear thousands and thousands of impacts and corrosion, which requires that the button on drilling bit distributes well-regulated in order to make bearing equally. When you use large-scale rock dill, the ball-shaped with double angle of chamfer is a better choice. On the contrary, cone and wedge is beneficial for prolong working life.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com