Enhanced Electrical Conductivity of BaCeO3-Based Composites By APT

- Details

- Category: Tungsten Information

- Published on Sunday, 06 June 2021 02:29

- Written by yuntao

- Hits: 1765

Materials with perovskite structure are considered as perspective for Solid Oxide Fuel Cells in their standard three-layer system anode/electrolyte/cathode and the innovative construction: symmetrical or single cell. Additionally, application of ceramic proton conductive electrolyte instead of typical for SOFC oxide ion conductive (e.g. yttria-stabilized zirconia, doped ceria) allows to decrease fuel cells working temperature and prevent fuel dilution by reaction products. Thus, perovskite structure ABO3-based materials, mainly BaCeO3 and BaZrO3, seem to be the interesting group for proton conductive fuel cells.

Read more: Enhanced Electrical Conductivity of BaCeO3-Based Composites By APT

Ammonium Paratungstate Utilized in Sulphur Removal of Diesel Fuels

- Details

- Category: Tungsten Information

- Published on Saturday, 05 June 2021 08:51

- Written by yuntao

- Hits: 1633

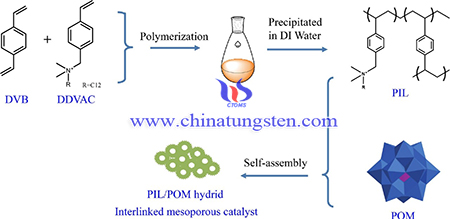

Sulfur compounds in fuel are converted into SOx when combusted. Furthermore, SOx in automobile exhaust degrades the catalytic converter performance resulting in increased NOx emission which is another important air pollutant. In recent years, ultra-low-sulfur diesel (ULSD) was required in many countries by mandating stringent legislation to cut the S-content down to 10 ppm. At present, the traditional hydrodesulfurization (HDS), a conventional commercial technology, is wildly employed in the purification of fuels. Although HDS can remove various S-compounds such as thiols, sulfides and disulfides, when the deep desulfurization of diesel fuel is required, HDS is less effective due to the low hydrogenation activity to heterocyclic thiophenic compounds

Read more: Ammonium Paratungstate Utilized in Sulphur Removal of Diesel Fuels

APT Applied in Tungsten Coated Catalysts for Thiophene Oxidation

- Details

- Category: Tungsten Information

- Published on Tuesday, 01 June 2021 00:57

- Written by yuntao

- Hits: 1698

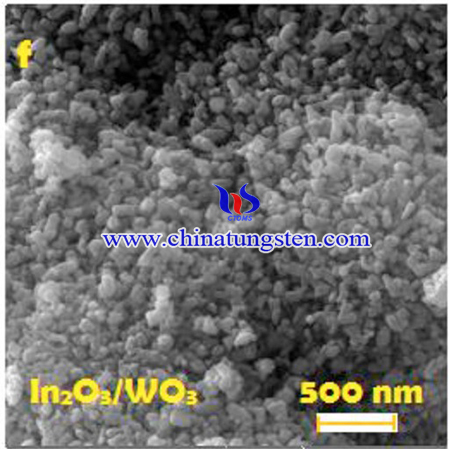

The more stringent limitations on the content of sulfur in the petroleum raw materials stimulated in recent years new research dealing with catalytic desulfurization processes. The key trend in the purification of liquid hydrocarbon raw materials is hydrotreatment in which sulfur is removed as hydrogen sulfide, which is then subjected to the Claus process to be converted to elemental sulfur.

Read more: APT Applied in Tungsten Coated Catalysts for Thiophene Oxidation

Preparation Method of Ultra Coarse Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Tuesday, 01 June 2021 17:33

- Written by Cristina

- Hits: 1556

Ultra coarse tungsten powder can not only be used to prepare high-toughness and high-density alloys, such as petroleum perforating bullets, heavy armor-piercing bullets and radiation protection materials, but also raw materials for the production of ultra-coarse tungsten carbide, which is mainly used for ultra-coarse-grained cemented carbide, then used for drill bits for oil drilling, mining, tunneling, hard coating spraying, etc.

Read more: Preparation Method of Ultra Coarse Tungsten Powder

Ammonium Paratungstate Applied in CO2 Conversion Into Methanol

- Details

- Category: Tungsten Information

- Published on Sunday, 30 May 2021 21:13

- Written by yuntao

- Hits: 1709

Read more: Ammonium Paratungstate Applied in CO2 Conversion Into Methanol

sales@chinatungsten.com

sales@chinatungsten.com