Quasi-Spherical Nanosized Tungsten Prepared by APT

- Details

- Category: Tungsten Information

- Published on Sunday, 27 June 2021 21:27

- Written by yuntao

- Hits: 1724

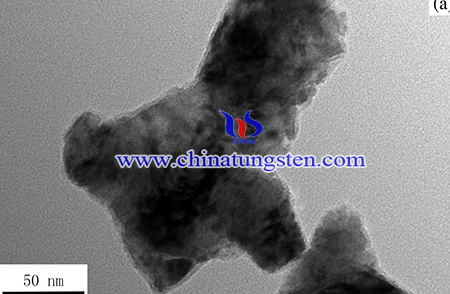

Tungsten has been widely used as structural materials in aerospace, military, and energy industries owing to its brilliant characteristics such as high mechanical strength and melting point, well thermal conductivity, and good resistance to oxidation. Generally, bulk tungsten is fabricated by powder metallurgy process and high density and fine grain size are critical to achieve outstanding mechanical properties such as the hardness of sintered compacts. Due to its high melting point of 3420 °C, the powder metallurgy process usually requires very high sintering temperatures of 2700–2800 °C to get near fully dense tungsten, which always leads to over growth of the grain size and deteriorates the mechanical properties.

Read more: Quasi-Spherical Nanosized Tungsten Prepared by APT

Preparation of Carbon-Coated Tungsten Trioxide with Enhanced Photocatalytic Activity Using Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Sunday, 27 June 2021 17:32

- Written by yuntao

- Hits: 1674

With the rising global energy supply and related environmental issues brough by burning of fossil fuels, various materials including nitrides, oxides, metals, metal chalcogenides and phosphides have been developed. Tungsten oxides (WOx) caught a lot interest because of their earth-abundance, highly tunable composition, high chemical stability at an appropriate pH value, and excellent electrical conductivity. Individually, WOx semiconductors has excellent performance in photocatalytic degradation of many organic pollutants.

Unfortunately, it has the drawbacks of low light adsorption and relatively narrow band gap. An effective and practical strategy is to design tungsten oxide composites with carbon. improve the photocatalytic ability by preparing the amorphous carbon-coated tungsten trioxide (WO3) with a high defect concentration. In order to overcome these disadvantages, WO3 had been doped with carbon to enhance its photocatalytic activity.

The fabrication method of carbon-coated tungsten trioxide is conducted as following procedures: All raw materials were of analytical grade and commercially available and used as received without further purification. The commercial WO3 was used for comparison.

0.01 mol ammonium paratungstate (APT), 0.24 mol ammonium nitrate (NH4NO3, ⩾ 99.0%), 0.1 mol glycine (C2H5O2N) and various contents of glucose (C6H12O6) were dissolved into deionized water, and then the solution was continuously stirred for a homogeneous state. The mixture was placed on an electrical furnace in air for thermal processing. The solution was evaporated with the formation of a gelatinous mass during heating. Upon further heating, the resultant mass swelled suddenly, accompanied by the release of a lot of gases. The whole process of swelling and combustion of gel indicates the non-explosive and self-propagating exothermic reaction, which took several minutes. The samples prepared with 0.017, 0.033, 0.05 and 0.067 mol glucose were described as G1, G2, G3 and G4, respectively.

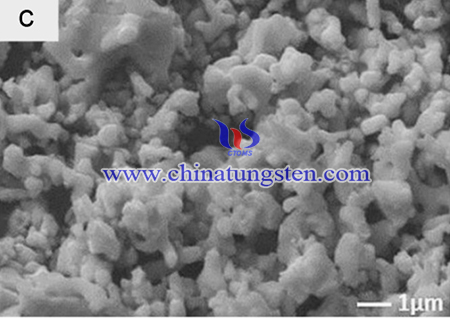

In summary, amorphous carbon-coated tungsten oxide nanocrystals were synthesized via with enhanced photocatalytic activity is prepared using ammonium paratungstate as starting material. Carbon-coated tungsten oxide existed in the form of round particles with size of ~ 150 nm and the WO3-x nanorods with the length of ~ 20 nm and diameter of 5 nm. The synthesized carbon coated WO3 showed a considerable rate for organic degradation under UV–visible light as well as good stability. This excellent performance is attributed to the synergistic effect of the amorphous carbon and the large amounts of defects. Moreover, the material demonstrated good photocatalytic stability under visible light after 5 recycling degradation of MB.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Fabrication of Nanosized Ammonium Paratungstate by Solid-gas Phase Reaction

- Details

- Category: Tungsten Information

- Published on Saturday, 26 June 2021 22:38

- Written by yuntao

- Hits: 1796

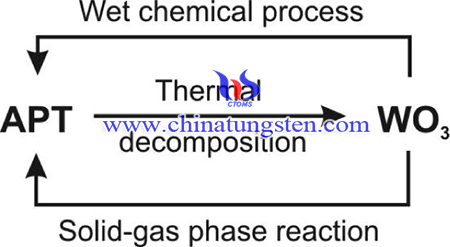

The ammonium paratungstate (APT) is the most important starting material in the tungsten industry, where usually its most stable APT·4H2O form is used. From APT tungsten oxides, tungsten carbides or tungsten metal can be prepared. Among others, tungsten oxides are widespread catalysts, photocatalysts, and gas sensors.

Read more: Fabrication of Nanosized Ammonium Paratungstate by Solid-gas Phase Reaction

Synthesis Process of Eu3+:Kla(WO4)2 Red Phosphors Using APT

- Details

- Category: Tungsten Information

- Published on Sunday, 27 June 2021 11:29

- Written by yuntao

- Hits: 1816

Lanthanide-doped luminescent materials have been studied extensively because of their wide applications in optoelectronic devices due to their interesting optical properties originating from the electron transitions among the 4f shell. Among these, alkali rare earth tungstates constitute a large family of inorganic compounds with the general formula ARE(MO4)2. These compounds possess tetragonal and monoclinic symmetries. Their structural diversity provides these crystals with numerous physical and chemical properties.

Read more: Synthesis Process of Eu3+:Kla(WO4)2 Red Phosphors Using APT

APT Utilized in Regeneration of V2O5-WO3/TiO2 SCR Catalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 26 June 2021 01:56

- Written by yuntao

- Hits: 1774

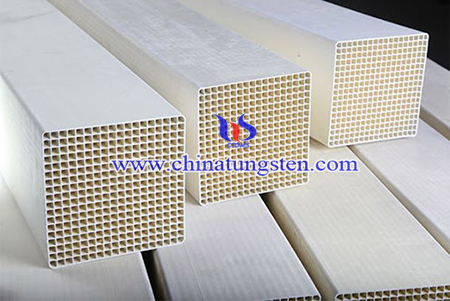

Nitrogen oxde poullution has been caught a lot attention due to its negative influence on environment. fly-ash emitted from coal combustion flue gas always carries various toxic substances, such as SO2, alkali metals and alkaline-earth metals. They tend to lower the efficiency of NOx removal and shorten the operating life-time of the SCR catalyst. V2O5-WO3/TiO2 has been greatly used in NOx removal applications.

Read more: APT Utilized in Regeneration of V2O5-WO3/TiO2 SCR Catalyst

sales@chinatungsten.com

sales@chinatungsten.com