W/TaC Composites as Plasma-Facing Materials Using Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Thursday, 08 July 2021 01:08

- Written by yuntao

- Hits: 1363

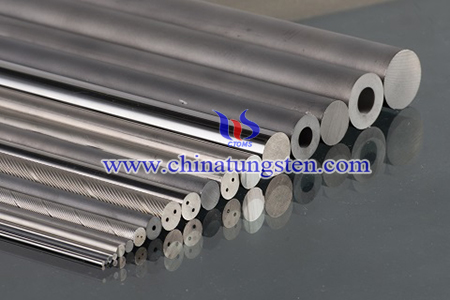

The development of high-performance plasma-facing materials (PFMs) is one of the key issues in realizing the safe application of nuclear fusion reactors. The extreme working environment of PFMs in fusion devices is primarily characterized by high thermal load, high-energy particle bombardment, and high flux hydrogen (H)/helium (He) plasma irradiation. Tungsten and its alloys are promising plasma-facing materials (PFM) that were used for the international thermonuclear experimental (ITER) divertor and have been regarded as the most promising plasma materials for future fusion reactors.

Read more: W/TaC Composites as Plasma-Facing Materials Using Ammonium Paratungstate

WO3/Titania Nanotubes with Improving Photocatalytic Activity Fabricated Using Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 July 2021 21:45

- Written by yuntao

- Hits: 1453

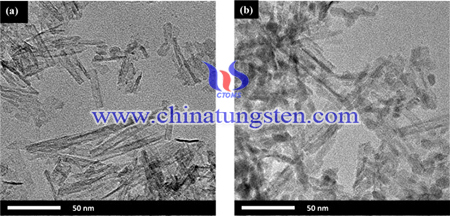

Titanium dioxide (Titania) has been utilized in photocatalysis since the discovery of the early 1970s. Since then, researchers have developed a variety of methods to tune the nanostructure and the composition to optimize the photocatalytic efficiency. Compared with nanoparticles or the bulk materials, nanotubular-structure titania possesses larger specific surface area and stronger adsorption capacity that results to a better photocatalytic effect. These unique chemical and physical properties allow titania nanotubes (TNT) to be widely used in sewage treatment, air purification, and sterilization areas.

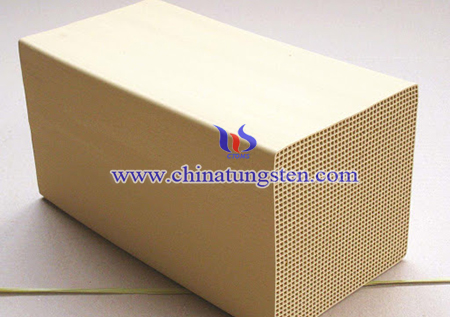

Recovery of Tungsten from SCR Catalysts as Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 July 2021 01:40

- Written by yuntao

- Hits: 1408

Read more: Recovery of Tungsten from SCR Catalysts as Ammonium Paratungstate

W/Tic Nanopowders Fabricated with APT by Wet Chemical Process

- Details

- Category: Tungsten Information

- Published on Tuesday, 06 July 2021 02:19

- Written by yuntao

- Hits: 1441

Read more: W/Tic Nanopowders Fabricated with APT by Wet Chemical Process

Synthesis of Nanosized Tungsten Carbide from Water Soluble Tungsten Source—APT

- Details

- Category: Tungsten Information

- Published on Monday, 05 July 2021 21:53

- Written by yuntao

- Hits: 1571

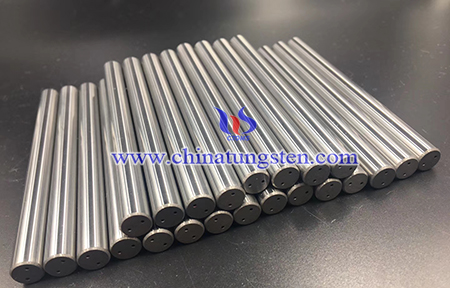

Thermal sprayed cemented carbides such as WC–Co(Cr) and Cr3C2–NiCr coatings are well known and widely used for wear protection purposes. Nanocarbides in cermets have shown promising results in gaining the hardness , wear performance in abrasion, cavitation or slurry type of wear conditions. Even friction properties have been reported to be improved by the use of nanocarbides. The driving force for reducing the carbide grain size comes from the fact that, as the carbide size becomes smaller, the binder mean free path is reduced, resulting in higher resistance to deformation and material loss. Many researchers have pursued such a hypothesis so as to improve the wear performance of HVOF WC–Co by reducing the WC grain size to the nanoscale.

Read more: Synthesis of Nanosized Tungsten Carbide from Water Soluble Tungsten Source—APT

sales@chinatungsten.com

sales@chinatungsten.com