Ammonium Metatungstate Preparing Solid Superacid

- Details

- Category: Ammonium Metatungstate

- Published on Tuesday, 15 November 2016 11:10

- Written by chunyan

- Hits: 2121

According to the classical definition, a superacid is an acid with an acidity greater than that of 100% pure sulfuric acid, which has a Hammett acidity function (H0) of −12. According to the modern definition, superacid is a medium in which the chemical potential of the proton is higher than in pure sulfuric acid. The known superacid can be divided into liquid and solid superacid according to the appearance. In petrochemistry, superacidic media are used as catalysts, especially for alkylations. Typical catalysts are sulfated oxides of titanium and zirconium or specially treated alumina or zeolites. The solid acids are used for alkylating benzene with ethylene and propylene as well as difficult acylations, e.g. of chlorobenzene.

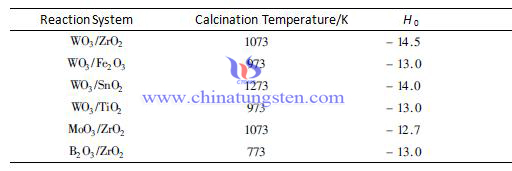

In 1998, the presence of supported oxide solid superacid has immediately caused a wave of research in the field of catalyst, which has been reported to have three types, namely WO3, MoO3 and B2O3 oxides, with the acidity showing as the following table:

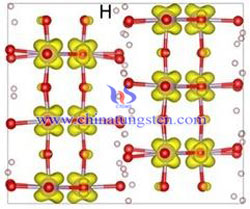

The supported oxide solid superacid (WO3/ ZrO2) which Arata firstly studied has the acidity lower than that of SO42- / MxOy-type solid superacid (SO42- / ZrO2) with H0 < -16.0 (while the H0 of WO3/ ZrO2 is lower than 14.5), but its stability in solution and reducing atmosphere and heat is better than that of SO42- / ZrO2 solid superacid; moreover, it is selectivity for some specific reactions, such as isomerization of high-carbon alkanes, is higher than that of SO42- / MxOy catalyst.

The results showed that ammonium metatungstate (AMT) can be used as a tungsten source for the preparation of supported oxide solid superacid (WO3/ ZrO2), with the preparation methods of coprecipitation and sol-gel method; both of the two methods are also called as one-step method since it is introducing WO3 at the same time of preparation process, the processes are:

1. Coprecipitation method: Pour the ZrOCl2 solution into a mixed solution of ammonium metatungstate and ammonia water to conduct coprecipitation, and adjust the final pH value to 9.0, then carry out filtering, washing, drying and calcination to get the final product.

2. Sol-gel method: Add the zirconium n-propoxide into the mixed solution of ethanol and nitric acid containing with ammonium metatungstate to get gelling; remove the ethanol by carbon dioxide supercritical drying method after the obtained gel is aged for 2 hours; and then dry it in vacuum for 3 hours respectively at temperature of 383 K and 523 K, and finally carry out calcination at high temperature.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Preparing Ammonium Dithiotungstate

- Details

- Category: Ammonium Metatungstate

- Published on Friday, 11 November 2016 13:58

- Written by chunyan

- Hits: 2143

Ammonium metatungstate (AMT) is an important intermediate compound in tungsten metallurgy industry, which is mainly used for manufacturing tungsten oxide, tungsten powder, tungsten wire and other tungsten compound, also, it is used in catalyst of petrochemical industry. Researches have indicated that ammonium metatungstate and ammonium sulfide solution can be used for preparing ammonium dithiotungstate under some specific environment.

Ammonium metatungstate (AMT) is an important intermediate compound in tungsten metallurgy industry, which is mainly used for manufacturing tungsten oxide, tungsten powder, tungsten wire and other tungsten compound, also, it is used in catalyst of petrochemical industry. Researches have indicated that ammonium metatungstate and ammonium sulfide solution can be used for preparing ammonium dithiotungstate under some specific environment.

There are two methods of ammonium metatungstate preparing ammonium dithiotungstate, as following:

The first method:

1. Dissolve ammonium metatungstate in the deionized water with stirring;

2. Add ammonia water and stir for 20 minutes to speed up the reaction speed under the temperature of 60°C, at this time, the pH value of reaction system may be 9;

3. Add ammonium sulfide solution and stir for 30 minutes under 60°C, then carry out vacuum filtration until the reaction is stop to remove a small amount of blue precipitation which generated during the reaction process;

4. Stand the filtrate for 24 hours under 0°C to get yellow crystal;

5. Carry out vacuum filtration and the precipitation is washed respectively with deionized water and anhydrous ethanol for three times, and finally we get the ammonium dithiotungstate crystal after drying, with the yield of 45%.

The second method:

1. Place the 5g of industrial grade ammonium tungstate which contains 83% of tungsten trioxide into conical beaker, and add 8 wt% of ammonium sulfide solution 35ml slowly, at this time the color of the solution will slowly turns from blue to light yellow;

2. Stir for 30 minute at room temperature after all the ammonium sulfide solution is poured into the conical beaker, and then stand the reactant solution for 12 hours to generate yellow crystal;

3. Precipitate, and wash the precipitation respectively with deionized water and anhydrous ethanol for three times, dry at room temperature in vacuum environment to finally get ammonium dithiotungstate crystal, the yield is 93% in accordance with tungsten content.

Ammonium dithiotungstate [(NH4)2WO2S2] is an important class of thiometal ammonium salt, and the decomposition products include {WOS2}, vulcanization intermediate of tungsten oxide. Studies have found that the thermal decomposition of ammonium dithiotungstate crystal under the atmosphere of hydrogen is mainly occurred among 160~450℃, which firstly transfers to {WOS2} and then to tungsten disulfide.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Preparing Radiation Shielding Non-Woven Fabric

- Details

- Category: Ammonium Metatungstate

- Published on Friday, 04 November 2016 08:56

- Written by chunyan

- Hits: 2131

With the rapid development of modern science and technology, all kinds of high-energy rays (such as X-ray) have been more and more widely applied. Besides, since people have put more and more concern to the protection of high-energy rays, and thus, the research and manufacture of X-ray protection materials is emerging in endlessly. There are three ways for X-ray protection, respectively time, distance and shielding protection. Wherein, the shielding protection is using or setting a kind of shielding material which can absorb the X-ray between human body and radiation source, thus to weaken or even eliminate the damage which X-ray brings to human body.

At present, the main X-ray protection material is the metal with high density, such as lead plate, lead rubber and compounds with lead, to shield the ionizing radiation of X-ray. However, as for personal radiation protection, lead oxide will firstly poison human body, and cause environmental pollution; secondly, the hard material will make human body uncomfortable.

For solving that problem, an invention has pointed out a method which takes ammonium metatungstate (AMT) as one kind of raw material component to prepare radiation shielding non-woven fabric. The radiation shielding non-woven fabric is some kinds of fabric with radiation shielding function which is formed by no need of spinning weaving. In this radiation shielding non-woven fabric, the weight ratios of all kinds of materials are: 1~10% of ammonium metatungstate (AMT), 5~20% of polyacrylonitrile copolymer and 80~95% of DMF, while the preparation steps are like following:

1. Weight the raw material of AMT, polyacrylonitrile copolymer and DMF according to weight ratio and get them into mixture solution, and then obtain spinning solution by ultrasonic standing deaeration;

2. Carry out electrostatic spinning process to the spinning solution which generated from step 1 to prepare grey cloth with nano or micron grade;

3. The grey cloth is carried out drying treatment and then went on preoxidation in the air;

4. Go on a carbonization after the grey cloth is finished preoxidation, then we will obtain the desired radiation shielding non-woven fabric.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Preparing Thermal Insulation Additive

- Details

- Category: Ammonium Metatungstate

- Published on Wednesday, 09 November 2016 15:49

- Written by chunyan

- Hits: 2210

Many metal oxides and some tungstate have the electrical conductivity and thermal insulation properties, and can be used as infrared shielding material. By heating the mixture solution of ammonium metatungstate (AMT) and alkali carbonate to 80°C, it can prepare some kind of tungsten oxide and tungsten bronze, and all these resulting substances can be used as the raw material of light transmission conductive films with infrared shielding property.

Thermal insulation additive is a kind of material which can stop the thermal conduction during heat transfer. Thermal insulation is the reduction of heat transfer (the transfer of thermal energy between objects of differing temperature) between objects in thermal contact or in range of radiative influence. Thermal insulation can be achieved with specially engineered methods or processes, as well as with suitable object shapes and materials. The insulating capability of a material is measured with thermal conductivity (k). Low thermal conductivity is equivalent to high insulating capability (R-value). In thermal engineering, other important properties of insulating materials are product density (ρ) and specific heat capacity (c).

Ammonium metatungstate to prepare thermal insulation additive, which is hydrogen tungsten bronze, is get ammonium metatungstate contact with hydrogen gas or reducing gas which can release hydrogen gas at a temperature of 2500K or higher, wherein the AMT can be replaced by ammonium paratungstate or ammonium hexametungstate and ammonium dodecatungstate and AMT hydrate; the reducing and releasing hydrogen include ammonia or volatile hydrocarbons such as ethane or propane, which may be used in place of hydrogen or as a mixture with hydrogen; in a plasma, in particular when the hydrogen and / or hydrogen-evolving gases are used in admixture with a noble gas.

In addition, a invention has pointed out a method for preparing insulating material with raw material of ammonium metatungstate, by preparing ammonium metatungstate solution as a precursor, then drying it to get AMT crystal; and then, reduce AMT at 100~500°C to generate composite tungsten oxide at the reaction condition, finally to form composite tungsten oxide film to play a role of heat insulation.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Price on Nov.2nd, 2016

- Details

- Category: Ammonium Metatungstate

- Published on Wednesday, 02 November 2016 17:51

- Written by Cristina

- Hits: 2128

Ammonium metatungstate price with purity over 91.40% from Chinatungsten Online is 35.50 USD/KG, by Chinatungsten FOB Xiamen, Nov.2nd, 2016.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com