Ammonium Metatungstate Catalyzing Preparation of 1 - Methyl Imidazole

- Details

- Category: Ammonium Metatungstate

- Published on Friday, 23 December 2016 16:37

- Written by chunyan

- Hits: 2175

1 - methyl imidazole is one of the important intermediate of imidazoles, which has extensive application in Ionic liquid epoxy resin and curing agent. The traditional synthetic methods of 1 - methyl imidazole are two-step and one-step process, wherein, two-step method is firstly condensing glyoxal and formaldehyde, ammonia water to generate imidazole, then going on a methylation reaction with the dimethyl sulfate finally get 1 - methyl imidazole, however, this process is using the highly toxic raw material of dimethyl sulfate, which will also higher the cost; the one-step method is taking glyoxal, formaldehyde, methylamine and ammonia water as raw materials, but this process exists the shortcomings of low yield, many more by-products and has more troublesome in separating and purifying.

One research has pointed out a new kind of synthesis methods of 1 - methyl imidazole, which is introducing the ammonium metatungstate column brace hydrotalcite as catalyst, using imidazole as raw material, and methanol as the methylation reagent, and through the fixed bed continuous method to directly synthesize 1 - methyl imidazole. The reaction equation is showing as the picture below:

The properties of this method to prepare 1 - methyl imidazole are as follows:

1. The molar ratio of imidazole and the methanol is optimized of 1:4 ~ 6;

2. The reaction conditions are: the pressure in the fixed bed is 0.4 ~ 0.6 MPa, the temperature shall be in 320 ~ 350°C, the reaction liquid feed quality airspeed is 0.3 ~ 0.4 / h;

3. The advantages of simple operation, less pollution and high yield, and is easy to be industrialized production;

4. Ammonium metatungstate (AMT) catalyst has high catalytic activity, small pollution to the environment, long life and other advantages;

5. The methanol used as methylation reagent will lower the cost of raw materials, and also has lower toxicity.

Ammonium metatungstate catalyst is a new kind of catalyst with better property. When methyl alcohol transfers to hydrocarbon, it shows great catalytic ability and unique selectivity. And thus, ammonium metatungstate is widely used in petroleum, electronic, national defense, aviation, metallurgy, anticorrosion and antiflaming, etc. It now becomes new catalytic material, and its application and consumption is increased day by day.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Price on Dec. 23th, 2016

- Details

- Category: Ammonium Metatungstate

- Published on Friday, 23 December 2016 09:59

- Written by Cristina

- Hits: 2144

Ammonium metatungstate price with purity over 91.40% from Chinatungsten Online is 35.60 USD/KG, by Chinatungsten FOB Xiamen, Dec. 23th, 2016.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate (AMT) Preparing Pt-Supported Tungsten Carbide Catalyst

- Details

- Category: Ammonium Metatungstate

- Published on Wednesday, 21 December 2016 16:37

- Written by chunyan

- Hits: 2135

Pt-supported tungsten carbide catalyst is uniformly loading the tiny metal platinum nanoparticles on the tungsten carbide carrier with highly dispersing, and both of tungsten carbide and platinum will play the synergistic effect, and thus to form a new type of fuel cell catalysts. Studies have shown that tungsten carbide (WC) can instead of platinum and other precious metal catalyst, and also had good ability to resist poisoning; moreover, its catalytic performance on hydrogen precipitation reaction has been confirmed.

Pt-supported tungsten carbide catalyst is uniformly loading the tiny metal platinum nanoparticles on the tungsten carbide carrier with highly dispersing, and both of tungsten carbide and platinum will play the synergistic effect, and thus to form a new type of fuel cell catalysts. Studies have shown that tungsten carbide (WC) can instead of platinum and other precious metal catalyst, and also had good ability to resist poisoning; moreover, its catalytic performance on hydrogen precipitation reaction has been confirmed.

Research points out a preparation method of high efficient hydrogen evolution electrode materials and fuel cell electric catalyst, which is Pt-supported tungsten carbide catalyst, the preparation steps are as follows:

1. Dissolve the ammonium metatungstate (AMT) and platinum salt in the distilled water in accordance with the mass ratio of 1:0.02~2, to prepare the mixed aqueous solution with 2.5 ~ 50 wt % of ammonium metatungstate after fully mixed;

2. Import the mixed aqueous solution obtained in step 1 into a spray dryer for spray drying, and then to obtain the precursor particles of spherical H2WO4/ platinum salt;

3. Put the spherical H2WO4/ platinum salt precursor particles in a reactor for roasting, and then goes on the reduction and carbonization; cool down the product to room temperature under the protection of inert gas after the reaction is completed until the dark grey products is generated, which is the Pt-supported tungsten carbide catalyst. Wherein, the mass ratio of metal platinum and carrier of tungsten carbide is 1~100:100, and tungsten carbide carrier has the morphology characteristics of mesoporous hollow spherical structure.

The development background of Pt-supported tungsten carbide catalyst:

1. Although the Pge electric catalyst has excellent electric catalytic activity, but the price is expensive;

2. Nickel and its alloy are also used for hydrogen evolution materials, but their chemical stability is really poor;

3. Fuel cell is expected to become the cleanest energy in the future since the high energy and efficiency, and friendly to environment and other properties, and thus to get a lot of attention.

In such circumstances, Pt-supported tungsten carbide catalyst is supposed to become the mainstream of the fuel cell non-noble metal catalysts.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate (AMT) Preparing Hollow Porous Tungsten Oxide Sphere by Spray Drying Method

- Details

- Category: Ammonium Metatungstate

- Published on Wednesday, 21 December 2016 16:40

- Written by chunyan

- Hits: 2191

Compared with the ordinary tungsten oxide, hollow porous tungsten oxide sphere because of the larger specific surface area, thus to has the significant size, surface, quantum size and macroscopic quantum tunneling effect, and thereby to expand the application areas, which can be used as a solar absorption, stealth and photocatalytic materials and gas sensitive materials of NOx, H2S and NH3 etc. Ammonium metatungstate (AMT) is an important intermediate compound in tungsten production industry, the excellent raw material for manufacturing tungsten oxide, tungsten powder, tungsten carbide powder and other tungsten products.

Compared with the ordinary tungsten oxide, hollow porous tungsten oxide sphere because of the larger specific surface area, thus to has the significant size, surface, quantum size and macroscopic quantum tunneling effect, and thereby to expand the application areas, which can be used as a solar absorption, stealth and photocatalytic materials and gas sensitive materials of NOx, H2S and NH3 etc. Ammonium metatungstate (AMT) is an important intermediate compound in tungsten production industry, the excellent raw material for manufacturing tungsten oxide, tungsten powder, tungsten carbide powder and other tungsten products.

A study was taking the ammonium metatungstate solution or a mixture of AMT and ammonium tungstate solution as raw material, to produce hollow porous tungsten oxide sphere through a combination of spray drying method and heat treatment, its technological process is: Preparing ammonium metatungstate solution or a mixture solution of AMT and ammonium tungstate, with the concentration of 200 g/L, then to prepare AMT or mixture of AMT and ammonium tungstate hollow powder; after putting the powder in a furnace to calcine for15-180 min under the temperature of 400-1000℃, we finally get made hollow porous tungsten oxide ball. Its properties are as follows:

1. The concentration of AMT and ammonium tungstate mixture solution is 200g/L, the mass ratio of AMT and ammonium tungstate is 4:1~1~4, heat treatment temperature is 400~1000°C, time of heat preservation is 15~180 min.

2. The spray drying method is using the ammonium tungstate solution, the concentration is 200 g/L, the heat treatment temperature of 400~1000°C, time of heat preservation for 15 ~ 180 min. Because when the temperature is below 400°C, the crystal growth speed is to slow and hard to generate porous; however, when the temperature is higher than 1000°C, the too fast growth speed of crystal will cause the nanosize particle of tungsten oxide hard to control, and thus it will easily get the coarse tungsten oxide particle which will reduce the specific surface area. While, when the heat preservation time is less than 15 minutes, the crystal growth is not completely; but when the holding time is higher than 180 min, it will come out combination of crystal and cause the coarse tungsten oxide particle.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate (AMT) Preparing Hexagonal Tungsten Oxide Ball

- Details

- Category: Ammonium Metatungstate

- Published on Thursday, 15 December 2016 16:51

- Written by chunyan

- Hits: 2181

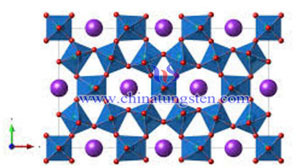

Hexagonal tungsten oxide ball (hex-WO3), which is the tungsten oxide ball with hexagonal crystal structure. Since the single crystal hexagonal tungsten oxide has an empty hexagonal space tunnel structure, the W contained compound will exit mixed valence states of W6+, W5+ and W4+ and so on, thus to make the overall compound in a balance charge state. This special structure and valence is making hexagonal tungsten oxide ball has well electro-optic effect and excellent electrical properties, thus it has widely been used in laser frequency doubling, optical signal processing, superconducting material, solid fuel cell and other fields.

Hexagonal tungsten oxide ball (hex-WO3), which is the tungsten oxide ball with hexagonal crystal structure. Since the single crystal hexagonal tungsten oxide has an empty hexagonal space tunnel structure, the W contained compound will exit mixed valence states of W6+, W5+ and W4+ and so on, thus to make the overall compound in a balance charge state. This special structure and valence is making hexagonal tungsten oxide ball has well electro-optic effect and excellent electrical properties, thus it has widely been used in laser frequency doubling, optical signal processing, superconducting material, solid fuel cell and other fields.

A study was taking glucose and ammonium metatungstate (AMT) as the raw materials to prepare hexagonal tungsten oxide ball by solid - phase thermal decomposition method, which is controlling the crystal morphology of tungsten oxide ball by adjusting the temperature in the reaction process. The manufacture steps are as follow:

1. Weight the ammonium metatungstate and glucose in accordance with a specific mass ratio, the mass ratio of AMT: glucose is preferred of 1:2.5;

2. Grind AMT and glucose crystal to the average particle size of 10nm~200μm, then put them in quartz boat after mixed uniformly;

3. Put the quartz boat with the raw materials in a tube furnace with inert gas atmosphere, and then rise the temperature to 850°C~900°C by the program temperature controlling to sinter for 5~6 hours, then we get the product of hexagonal tungsten oxide ball after cutting down the current and natural cooling.

The particle size of hexagonal tungsten oxide ball obtained in this method is among 40μm~80μm, and there is no agglomeration between the spheres; moreover, the tungsten oxide nanorods are regularly attached to the surface of the ball, which have a length of 1μm~5μm. This solid - phase thermal decomposition method to prepare tungsten oxide has the benefits of less raw materials (AMT and glucose) required, simple ingredient and process, nom pollution to the environment, high purity of product, short cycle and small consumption of energy and so on, thus to be benefit for industrial production, also it has provided a new way for preparing nano materials at the same time.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com