Ammonium Metatungstate Preparing Nano Tungsten Oxide Aqueous Solution

- Details

- Category: Ammonium Metatungstate

- Published on Monday, 05 December 2016 15:59

- Written by chunyan

- Hits: 2059

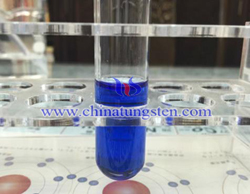

Nano tungsten oxide can not soluble in water itself, the so called nano tungsten oxide aqueous solution is the dispersion which nano tungsten oxide particles are uniformly distributed in water, to play the roles of oxidization and reunion of tungsten oxide. Tungsten oxide is the typical transition metal oxides, while the nano tungsten oxide is a new type of functional material, and because of its excellent discoloration performance, it can be widely used in many fields, such as intelligent window, large area flat panel display, gas sensor, dye-sensitized solar cell, automatic mirror, energy storage.

Nano tungsten oxide can not soluble in water itself, the so called nano tungsten oxide aqueous solution is the dispersion which nano tungsten oxide particles are uniformly distributed in water, to play the roles of oxidization and reunion of tungsten oxide. Tungsten oxide is the typical transition metal oxides, while the nano tungsten oxide is a new type of functional material, and because of its excellent discoloration performance, it can be widely used in many fields, such as intelligent window, large area flat panel display, gas sensor, dye-sensitized solar cell, automatic mirror, energy storage.

Ammonium metatungstate (AMT) is the important intermediate compound of tungsten metallurgy, and being the important raw material for manufacturing tungsten oxide, tungsten and tungsten carbide powder and other tungsten products. An invention has proposed one method to prepare nano tungsten oxide aqueous solution from the raw material of ammonium metatungstate and sodium borohydride, with the steps like bellows:

1. Weight the appropriate amount of ammonium metatungstate and sodium borohydride according to the mass ratio of 1~10:1;

2. Add the AMT powder into deionized water to dissolve with stirring and get the ammonium metatungstate aqueous solution with the concentration of 5~50%;

3. Add the weighted sodium borohydride solid into the AMT solution and stir to mix them uniformly, stay to react for 10~60 minutes under the room temperature to 95°C to get the blue nano tungsten oxide aqueous solution with 0.1〜10nm uniform particle size. since the ammonium metatungstate will react with sodium borohydride to generate blue nano WO2.9, and it will release heat, a large number of hydrogen gas and ammonia gas during the reaction process, which will remove purity of ammonium ion.

Nano tungsten oxide aqueous solution prepared by this method has the advantages of good stability, small particle size of nano tungsten oxide and others, thus to have wide application in intelligent window, gas sensor and solar energy cell and other fields.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Preparing Nanoscale Zirconium Tungstate Hollow Sphere

- Details

- Category: Ammonium Metatungstate

- Published on Wednesday, 30 November 2016 17:28

- Written by chunyan

- Hits: 2193

The cubic zirconium tungstate is one of the hotspots in the research of negative thermal expansion materials, with its widest range of negative expansion effect, high negative expansion coefficient and isotropy and other advantages, it can be combined with positive expansion into the specific materials with zero or low expansion, and thus to be used in the some devices which is used under extreme temperature conditions field of aerospace. The preparation methods of zirconium tungstate are solid phase sintering, sol-gel, combustion, chemical coprecipitation and microwave method ect., however, the zirconium tungstate particles or whiskers prepared by these methods are irregular, and can not be used in some specific fields, such as aerospace.

There is an invention disclosed a method for preparing nanoscale zirconium tungstate hollow sphere by hydrothermal synthesis method from the raw materials of ammonium metatungstate (AMT) and zirconium oxychloride, with the steps as following:

1. Respectively weight the right amount of ammonium metatungstate and zirconium oxychloride according to the stoichiometric ratio of zirconium tungstate (ZrW2O8), respectively, and prepare zirconium oxychloride aqueous solution and ammonium metatungstate aqueous solution respectively;

2. Add zirconium oxychloride aqueous solution into ammonium metatungstate aqueous solution under the condition of stirring, then preheat the mixture at the temperature of 60~70℃ with stirring continuous;

3. Add hydrochloric acid solution with continuously stirring, and then heat the solution to 80~100℃, then we get the zirconium tungstate precursor suspension after keeping the temperature for a proper time;

4. The zirconium tungstate precursor suspension is carried out a hydrothermal reaction at a temperature of 170~190℃, followed by cooling, collecting the precipitate and washing to remove chloride ions (Cl- ), drying, calcining at 800~1000℃, and finally to obtain nanoscale zirconium tungstate hollow sphere.

In this method of preparing zirconium tungstate by using AMT as raw material, due to the hydrothermal synthesis method can truly realize synthesizing zirconium tungstate powder at a low temperature, cut down the synthesis time of the precursor and control the direction of crystal growth; thus, the prepared nanoscale zirconium tungstate hollow sphere has the benefits of uniform particle size, good negative expansion performance and low density ect., and to have great potential for applying in aerospace field.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Arsenic Doped Ammonium Metatungstate Preparing Nano Tungsten Powder

- Details

- Category: Ammonium Metatungstate

- Published on Monday, 28 November 2016 16:28

- Written by chunyan

- Hits: 2248

Arsenic doped ammonium metatungstate (AMT) is generated by adding ammonium metatungstate into the nitric acid solution of elemental arsenic and stirring, drying and grinding, the excellent raw material for preparing nano tungsten powder. Nano tungsten powder is the tungsten powder which the particle size is fine to nanoscale, at present, the traditional method for manufacturing nano tungsten powder is tungsten oxide reduction method, wherein the reducing agent maybe hydrogen or carbon; with the appearing of nano materials, the manufacture methods of nano tungsten powder are emerging constantly, such as high-energy ball milling, gas evaporation, plasma, self-propagating high-temperature reduction and molten salt electrolysis method.

Arsenic doped ammonium metatungstate (AMT) is generated by adding ammonium metatungstate into the nitric acid solution of elemental arsenic and stirring, drying and grinding, the excellent raw material for preparing nano tungsten powder. Nano tungsten powder is the tungsten powder which the particle size is fine to nanoscale, at present, the traditional method for manufacturing nano tungsten powder is tungsten oxide reduction method, wherein the reducing agent maybe hydrogen or carbon; with the appearing of nano materials, the manufacture methods of nano tungsten powder are emerging constantly, such as high-energy ball milling, gas evaporation, plasma, self-propagating high-temperature reduction and molten salt electrolysis method.

There is a study to take ammonium metatungstate as raw material, and through doping process to get arsenic doped ammonium metatungstate to finally get nano tungsten powder, with the producing process like the following:

1. Preparation of arsenic doped ammonium metatungstate precursor composite powder

Add a certain amount of elemental arsenic into the nitric acid with a certain concentration, then add ammonium metatungstate into the nitric acid solution of elemental arsenic after the As is completely dissolved with the arsenic content being controlled; electric mix the raw materials, then dry them in a oven under 70~90°C for 8~10 hours, and then, grind to get arsenic doped ammonium metatungstate precursor compound powder.

2. Arsenic doped ammonium metatungstate calcination to prepare yellow tungsten trioxide powder

Put the prepared arsenic doped ammonium metatungstate precursor compound powder in a box type resistance furnace at the temperature of 580~620°C to carry out calcination in air atmosphere for 2~3 hours, then we get yellow tungsten trioxide powder.

3. Tungsten trioxide reduction to generate nano tungsten powder

Put the yellow tungsten trioxide powder in a tube furnace to get reduction by inletting hydrogen, under the reduction temperature of 780~820°C with the heating rate of 5°C/min, and the heat preservation time of 3~4 hours, to finally manufacture nano tungsten powder

The nano tungsten powder get by arsenic doped ammonium metatungstate has the advantages of good dispersion, and uniform particle size distribution, thus to effectively promote the development and application of nano-crystal WC-Co alloy.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Price on Nov.29th, 2016

- Details

- Category: Ammonium Metatungstate

- Published on Tuesday, 29 November 2016 14:42

- Written by Cristina

- Hits: 2113

Ammonium metatungstate price with purity over 91.40% from Chinatungsten Online is 35.50 USD/KG, by Chinatungsten FOB Xiamen, Nov.29th, 2016.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Ammonium Metatungstate Price on Nov.25th, 2016

- Details

- Category: Ammonium Metatungstate

- Published on Friday, 25 November 2016 09:50

- Written by Cristina

- Hits: 2093

Ammonium metatungstate price with purity over 91.40% from Chinatungsten Online is 35.50 USD/KG, by Chinatungsten FOB Xiamen, Nov.25th, 2016.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com