Factors Affect Tungsten Trioxide Electrochromic Film

- Details

- Category: Tungsten Information

- Published on Monday, 11 July 2016 18:08

Tungsten trioxide ceramic target because of its low cost, simple preparation, easy to doping, in favor of the preparation of porous films and other features, is gradually valued by the people. The storage time refers to the film faded naturally to the △T less than a certain value after it colored (usually means the required time of 20%). When the electrochromic used in smart windows, electronic bulletin boards, and other fields, while higher the rate of coloring of film, extending the storage time of discoloration to longer the chromogenic time after one voltage colored, which has a very great significance in terms of environment protection and energy saving.

Tungsten trioxide ceramic target because of its low cost, simple preparation, easy to doping, in favor of the preparation of porous films and other features, is gradually valued by the people. The storage time refers to the film faded naturally to the △T less than a certain value after it colored (usually means the required time of 20%). When the electrochromic used in smart windows, electronic bulletin boards, and other fields, while higher the rate of coloring of film, extending the storage time of discoloration to longer the chromogenic time after one voltage colored, which has a very great significance in terms of environment protection and energy saving.

Preparation of tungsten trioxide electrochromic film:

1. Use tungsten trioxide powder of purity of 99% as raw material and adhesives for ball milling, drying, press-formed;

2. Calcine tungsten trioxide under 1200°C in a resistance furnace until it turns to polycrystalline ceramic target, after polished smooth we get the sputtering targets;

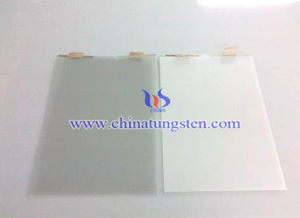

3. Use the conductive glass as substrate material to sputter deposition for 1 hour, to get the electrochromic film.

The experimental results show that use tungsten trioxide ceramics sintered target by RF reactive magnetron sputtering process for preparing electrical electrochromic film has the following properties:

1. The optimum amount of the tungsten trioxide is 60%, pressure of 2.5 Pa, the power about 145 W;

2. Test result shows that its optical modulation amplitude is up to 89.3%;

3. XRD tests show that the film appears in amorphous when it isn’t through vacuum heat treatment, and when the temperature reaches about 300°C, it began to appear more pronounced crystallization phenomenon;

4. After the heat treatment of 300 ° C, the optical modulation amplitude of the electrochromic film turns a slight increased, and the color storage capacity has been enhanced which is more than 32 hours; the same time, the storage capacity of ion increased to 3.96mC/cm3;

5. Cycle tests showed that after treated under the moderate temperatures (300°C), the properties of the film changed a little during the cycle, which indicates that its server life does not shorten; however, the heat treatment increases the density of the electrochromic film, thus to result the response slower;

6. When the heat treatment temperature is higher than 300°C, the color storage time of film is increased slightly, but the other properties are greatly attenuated, which shows that, 300°C is the after plating optimum heat treatment temperature, the film can obtain the best performance at this time.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com