Working Mechanism of Rare Earth Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Friday, 08 July 2016 17:40

The working mechanism of rare earth tungsten electrode mainly relies on rare earth tungstate or oxytungstate migration and proliferation in the arcing process, which can achieve the best rare earth optimization ratio in electrode surface. And it can reduce the work function of the electrode surface, promoting electron emission, to improve the welding performance.

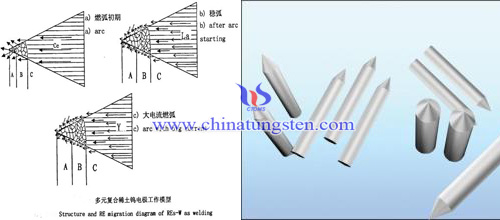

Multiple composite rare earth tungsten electrodes at different arcing time have different morphology and rare earth content change. During early arcing, under the action of high-frequency arc, the tip temperature of the electrode is higher, so that the fibrous tissue material shows three different regional characteristics. A area has the highest temperature and the organization presents the semi-molten state. Besides, the surface has tungsten oxide decomposition, so there has small amount of tungsten deposition. What’s more, due to highest temperature of the A area, so the amount of material evaporated within this area is the largest. B area occurred recrystallization and organization is equiaxed. Rare earth in B area presents liquid state and mainly along the grain boundary migrate to the surface, but equiaxed tungsten grains to some certain extent hindered diffusion migration of rare earth, so in this are the diffusion and evaporation is easy to achieve a balance,to form a stable active layer in the electrode surface, which is good for stabilizing arcing and promoting welding performance. C area maintains electrode original processing state of fibrous tissue. In composite electrode, Ce occurred first diffusion to the surface, so during early arcing stage, the role of Ce is the largest. In addition, the diffusion of rare earth in B area and C area is similar and there will take place Ce-based rare earth intergranular diffusion, but since C area tungsten grains exhibit fibrous tissue which parallels with electrode axis, so rare earth mainly migration to the B area.

After stable arcing, the electrode tip temperature is higher than initial arcing stage which has been significantly improved, especially in areas B and C. B area temperature rises to speed the evaporation rate of Ce and reduce the surface content. And the La also diffuse to the surface and it is possible to maintain a larger coverage of the electrode surface, which plays an important role on arcing stable. C area temperature increase can speed La diffusion along the grain boundary rate, so La as the main element along fibrous grain boundary diffuse to the B area, supplementary evaporation of rare earth.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com