Gradient Tungsten Carbide Button

- Details

- Category: Tungsten Information

- Published on Tuesday, 31 May 2016 16:56

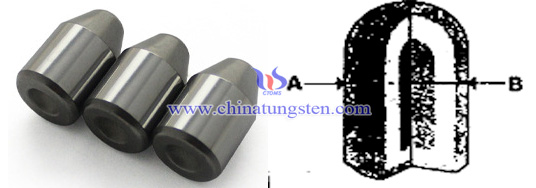

Gradient tungsten carbide button is also known as tungsten carbide button with gradient structure or multi-phase tungsten carbide buttons. The hardness of tungsten carbide is closely related to the granularity of WC and Co. In general, higher content of WC, the grains finer and the hardness is higher; while higher content of Co, the hardness is correspondly lower. Gradient tungsten carbide button has different hardness distribution due to the uneven structure. And the three layer micro-structure of gradient tungsten carbide buttons has significant differences: Since the WC particles enriched in surface layer, which has a high hardness; the intermediate layer distributes more Co phase, so the hardness is relatively low; internal contains a lot of W phase, the hardness is relatively high.

Throughout the process of carburizing, with the carburizing time goes by, Co alloy surface with constant migration to the alloy of the intermediate layer, the intermediate layer of Co alloy phase content increases with the carburization time. At the same time, the alloy surface WC grains occur grow inside the alloy due to the dissolution when carburizing sintering - precipitation mechanism of action, WC grains have a slight tendency to grow up. Such a sandwich structure can be simultaneously improved surface hardness and internal toughness and can effectively reconcile the contradiction between the wear resistance and the strength of tungsten carbide buttons.

To change the distribution of the alloy binder phase of cemented carbide base cemented carbide substance gradient structure is to take the lack of carbon in the system that is η- phase containing the carburizing process, it was low structure, so that different parts of the materials to achieve different performance. At present, the main process of tungsten carbide button with gradient structure includes compound hard metal technique, powder layering compression (with different binder content), metal melt impregnation and so on.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com