Effect of Cu Content on Tungsten Copper Electrode Micro-structure

- Details

- Category: Tungsten Information

- Published on Monday, 01 February 2016 17:04

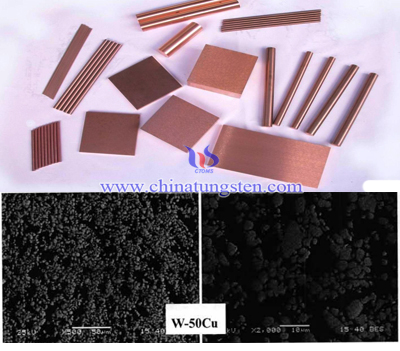

We can observe that sample with higher Cu content has smaller average granularity at the same sintering temperature and holding temperature by analyzing the picture of tungsten copper electrode micro-structure scanning electron microscope (SEM) after infiltration. This is due to increased copper content of the tungsten particles beneficial rearrangement, but also to promote the role of liquid copper segregation, so that the tissue sample composition is unevenly distributed. While the liquid copper segregation would to some extent caused by a corresponding tungsten particles contact with each other, which also reached a solid-phase sintering conditions will lead to further agglomerated tungsten particles, especially evidently in tungsten copper W-50Cu electrode sample. The following is a microwave Infiltration prepared tungsten copper alloy electrode scanning electron microscopy (SEM) photograph, showing the tungsten (W) grains agglomeration is a more clear and intuitive:

Compared with the micro-structure of tungsten copper electrode in conventional infiltration, microwave infiltration has higher heating rate, which is beneficial for copper liquid flowing and uniform distribution, so it has better uniformity and stability of structure. In addition, in the lower copper content, microwave Infiltration tungsten copper alloy electrode samples may also have a more clear view of the elongated rod dispersed tungsten grains W grow; low Cu content of tungsten copper electrode by conventional infiltration has inhomogeneous distribution of tungsten (W) particles, and like a nearly spherical or oval, which not only has tungsten particles with large granularity, but also has the small granularity. Accordingly, we can also make further concluded that the adverse effects of conventional infiltration microstructure produced for its relatively slow rate of temperature rise there is a certain correlation (conventional infiltration heating rate is generally 5 ℃ / min, while the microwave Infiltration the heating rate is generally 30 ℃ / min).

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com