How Strong Is the Burnout Resistance of Lanthanum Tungsten Electrode?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:37

During high-temperature, high-energy arc welding, the electrode tip is subjected to multiple stresses, including intense thermal shock, electrochemical reactions, and metal evaporation. These stresses can cause tip burnout and shape degradation, ultimately impacting weld quality and production efficiency.

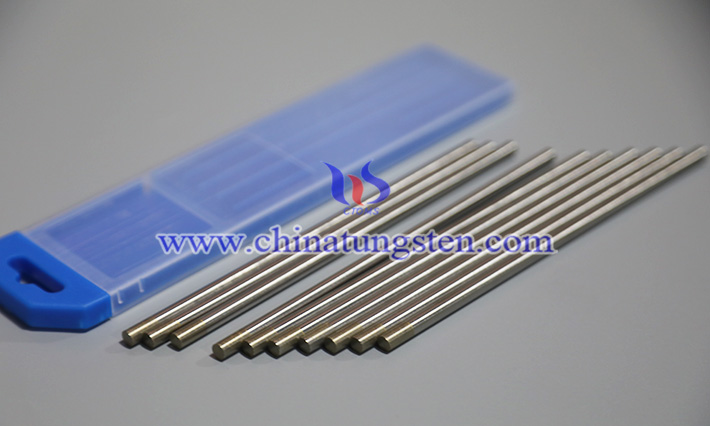

For welding engineers and manufacturers, selecting an electrode material with strong burnout resistance not only improves welding stability but also effectively reduces consumable costs and equipment maintenance frequency. Among various tungsten-based electrodes, lanthanum tungsten electrodes have become a key choice in the industrial field due to their excellent burnout resistance.

1. Structural advantages determine the ability to resist burning

Lanthanum tungsten electrode is made by doping a high-purity tungsten matrix with 1.0 % to 2.0% lanthanum oxide La₂O₃. This rare earth oxide is nonvolatile at high temperatures and is stably distributed within grain boundaries, strengthening the high-temperature structure of tungsten. This not only inhibits grain coarsening but also reduces the evaporation rate of tungsten at high temperatures, significantly slowing tip ablation and deformation.

In contrast, pure tungsten electrodes are prone to developing a melt ball, blunting, or even collapse under high current or prolonged welding conditions. Tungsten vapor escapes in high temperatures, causing the electrode to lose its tip geometry and affecting arc concentration. Lanthanum tungsten, through the "pinning effect" of rare earth particles, significantly improves heat resistance and maintains the integrity and structural stability of the electrode tip.

2. Long-term welding is not easy to collapse

In actual use, the tip shape of the lanthanide tungsten electrode remains good even if the welding current is continuously welded for dozens of minutes within the range of 120~200 amperes, and there is no obvious melting or collapse on the surface. This performance is particularly important for automated welding or robotic welding systems, because frequent replacement of electrodes not only reduces production capacity, but also leads to deviations in weld consistency.

In pulse welding or high-frequency arcing conditions, this type of electrode can also withstand frequent thermal cycles and show strong resistance to thermal fatigue. Its burnout rate is 10% to 20% lower than that of thoriated tungsten electrodes and more than 30% lower than that of pure tungsten electrodes. It is one of the most resistant non-radioactive materials to ablation.

3. Adapt to various working conditions and have stable anti-burning performance

Lanthanide tungsten electrodes are not only suitable for DC negative connection (DCEN) environments, but can also be used under some AC welding (AC) conditions. Especially in the welding of metals with strong thermal conductivity and high melting points such as aluminum, copper, stainless steel, and carbon steel, they can effectively withstand high heat loads and maintain good arc stability, reducing the frequency of tip ablation.

In addition, a reasonable grinding method can also help further improve its anti-burning performance. It is recommended to use a cone angle of 60°~90° and a smooth surface without burrs, which is not only conducive to arc concentration, but also can delay tip burning. If combined with high-purity argon (99.999%) and a stable gas flow, its service life can be further extended.

4. Give equal weight to service life and economy

Thanks to its strong resistance to burning, the service life of lanthanum tungsten electrode in industrial welding is much longer than other non-rare earth tungsten materials. According to actual feedback, a WL20 model (2% lanthanum) electrode can support continuous welding of more than 30 to 50 meters of welds or achieve tens of thousands of arc starts under standard conditions of use, and does not require frequent grinding, greatly saving labor and consumables costs.

In addition, it does not contain radioactive elements, is safe and environmentally friendly, and complies with the EU RoHS and REACH directives. It is particularly suitable for industries with high requirements for material safety, such as medical, aerospace, nuclear industry, and electronic manufacturing.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com