Materials for Tungsten Cemented Carbide Balls

- Details

- Category: Tungsten Information

- Published on Friday, 12 September 2025 16:37

- Written by Zhenghua

- Hits: 11

I. Main Materials for Tungsten Cemented Carbide Balls 1. Tungsten Carbide (WC):

This is the primary component of tungsten cemented carbide balls. It possesses extremely high hardness and wear resistance, and serves as the core material providing the ball's strength.

Surface Quality Inspection Methods for Tungsten Cemented Carbide Balls

- Details

- Category: Tungsten Information

- Published on Friday, 12 September 2025 16:35

- Written by Zhenghua

- Hits: 10

Due to their high hardness, wear resistance, and excellent mechanical properties, tungsten cemented carbide balls are widely used in precision bearings, valve seals, and measuring instruments. Their surface quality directly impacts service life, sealing performance, and operating accuracy, making surface quality inspection a critical step in production and application. Surface quality inspection primarily focuses on defects (such as cracks, pits, scratches, and pores), roughness, uniformity, and residual stress. The following introduces several commonly used inspection methods, combining traditional techniques with modern nondestructive testing methods to address various precision requirements and production scenarios.

Read more: Surface Quality Inspection Methods for Tungsten Cemented Carbide Balls

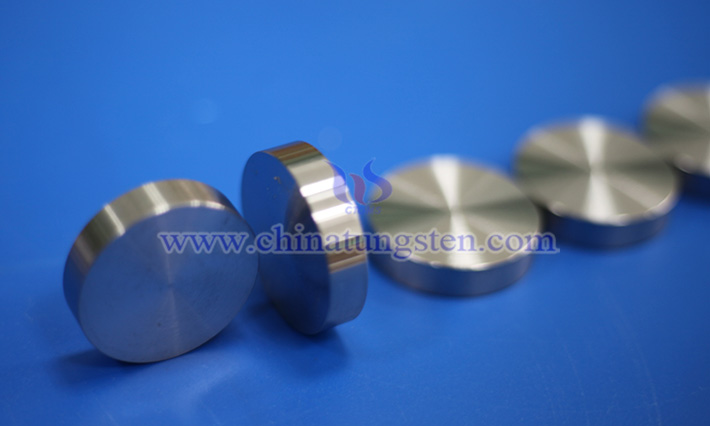

Tungsten Alloy Discs: The "Hardcore" Backbone of the Target Field

- Details

- Category: Tungsten Information

- Published on Friday, 12 September 2025 15:45

- Written by Xiaoting

- Hits: 20

Tungsten (W), renowned as the "industrial tooth" for its high hardness, wear resistance, and chemical stability, plays a pivotal role in materials chemistry and manufacturing. As a refractory metal, tungsten’s atomic structure imparts a high melting point and excellent mechanical strength. When alloyed with elements such as nickel, titanium, or tantalum and formed into discs, its applications in the target field demonstrate outstanding performance.

Read more: Tungsten Alloy Discs: The "Hardcore" Backbone of the Target Field

Tungsten Carbide Balls Quality Control

- Details

- Category: Tungsten Information

- Published on Friday, 12 September 2025 16:28

- Written by Zhenghua

- Hits: 11

Quality control of tungsten carbide balls is critical to ensuring their performance meets application requirements. This requires comprehensive management from raw materials and production processes to finished product testing, combining advanced testing methods with rigorous process monitoring to ensure stable product performance.

Tungsten Alloy Discs: A Regulating Material in the Counterweight Field

- Details

- Category: Tungsten Information

- Published on Friday, 12 September 2025 15:42

- Written by Xiaoting

- Hits: 18

Tungsten alloy discs, leveraging their exceptional mechanical, thermal, and chemical properties, have become a critical high-performance material in the counterweight field. CTIA GROUP LTD tungsten alloy discs primarily consist of tungsten as the core component, supplemented with elements such as nickel, iron, and copper, and are manufactured through powder metallurgy processes. They are widely applied across various scenarios, from precision instruments to heavy equipment.

Read more: Tungsten Alloy Discs: A Regulating Material in the Counterweight Field

sales@chinatungsten.com

sales@chinatungsten.com