Durability of Tungsten Wire in High-Temperature Furnaces

- Details

- Category: Tungsten Information

- Published on Monday, 11 August 2025 19:07

- Written by Zhenghua

- Hits: 96

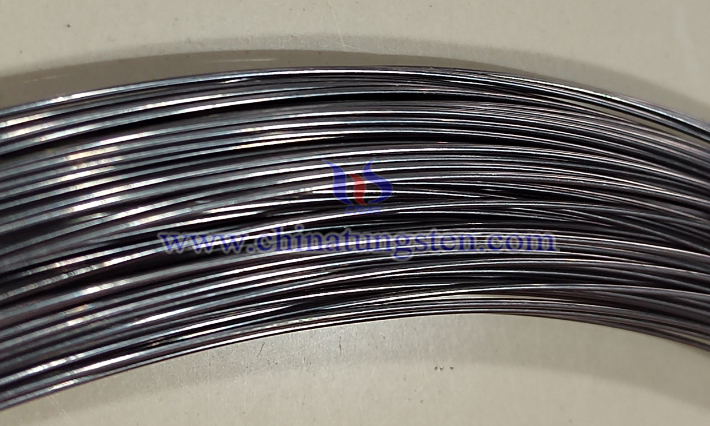

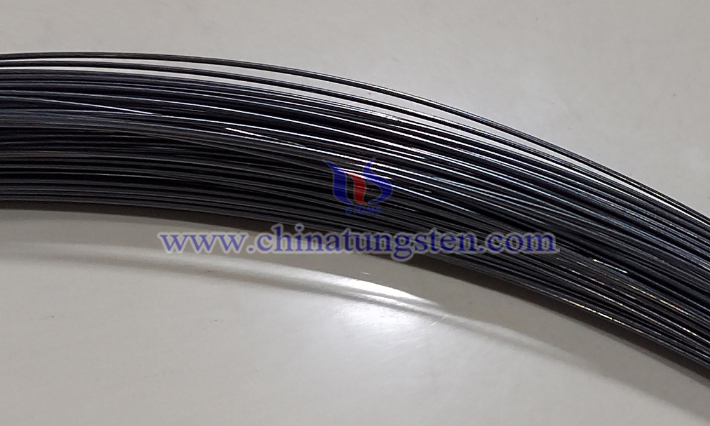

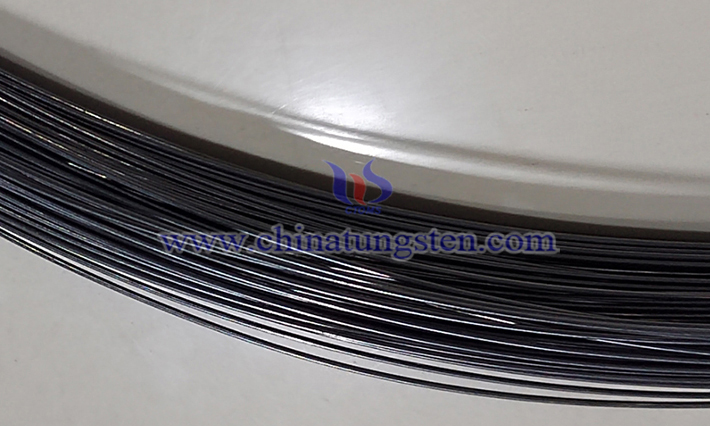

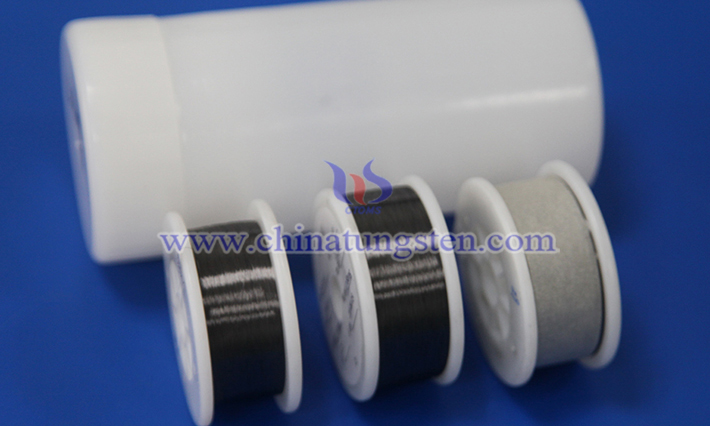

The durability of tungsten wire in high-temperature furnaces depends primarily on its material properties, environmental conditions, and usage.

Read more: Durability of Tungsten Wire in High-Temperature Furnaces

Tungsten Wire for Ceramic Sintering Heating

- Details

- Category: Tungsten Information

- Published on Monday, 11 August 2025 19:05

- Written by Zhenghua

- Hits: 80

Tungsten wire, as a high-temperature heating material, is often used as a heating element in ceramic sintering due to its high melting point, excellent electrical conductivity, and high-temperature resistance.

Tungsten Wire as a Component of High-Temperature Industrial Furnaces

- Details

- Category: Tungsten Information

- Published on Monday, 11 August 2025 19:01

- Written by Zhenghua

- Hits: 87

Tungsten wire is a key component in high-temperature industrial furnaces due to its excellent high-temperature resistance and electrical resistance.

Read more: Tungsten Wire as a Component of High-Temperature Industrial Furnaces

Applications of Tungsten Wire in Metal Smelting Furnaces

- Details

- Category: Tungsten Information

- Published on Monday, 11 August 2025 19:03

- Written by Zhenghua

- Hits: 84

Tungsten wire is widely used in vacuum melting furnaces, induction furnaces, electron beam melting furnaces, and other equipment, particularly in smelting processes requiring high-purity metals or special alloys in industries such as aerospace, nuclear, and electronics.

Read more: Applications of Tungsten Wire in Metal Smelting Furnaces

The Heating Effect of Tungsten Wire in a Vacuum Furnace

- Details

- Category: Tungsten Information

- Published on Monday, 11 August 2025 18:59

- Written by Zhenghua

- Hits: 85

The heating effect of tungsten wire in a vacuum furnace primarily relies on its high melting point, high resistivity, and low vapor pressure. It generates high temperatures through resistive heating and transfers heat through radiation, making it suitable for a variety of high-temperature processes.

Read more: The Heating Effect of Tungsten Wire in a Vacuum Furnace

sales@chinatungsten.com

sales@chinatungsten.com