US Congress Met Water Pollution, WO3 Photocatalyst Solves Lead Pollution

- Details

- Category: Tungsten's News

- Published on Thursday, 07 July 2016 18:23

- Written by chunyan

- Hits: 509

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide Photocatalyst Solves Mercury Pollution

- Details

- Category: Tungsten's News

- Published on Thursday, 07 July 2016 18:20

- Written by chunyan

- Hits: 829

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Surface Morphology during Tungsten Electrode Operation

- Details

- Category: Tungsten's News

- Published on Wednesday, 06 July 2016 18:49

- Written by yiping

- Hits: 652

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

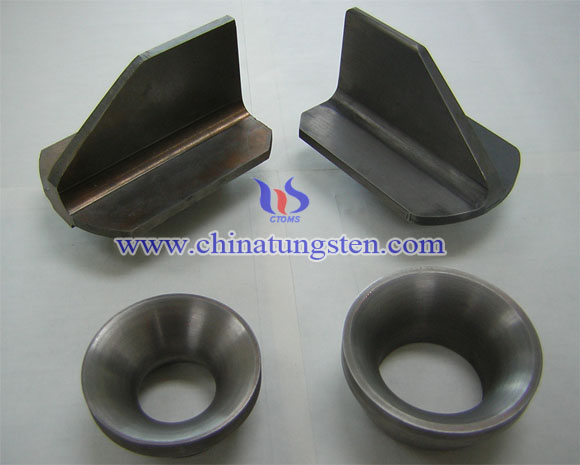

Tungsten Copper Tube Type Divetor Component Developed Successfully

- Details

- Category: Tungsten's News

- Published on Thursday, 07 July 2016 15:19

- Written by tang

- Hits: 632

Chinese Academy of Sciences for the ITER plasma has developed through tungsten copper tube type divertor components small modules completed high heat load test on the specified test platform, six test modules submitted all through testing and certification. It indicates that Chinese scientists have already with capacities that developed tungsten copper tube type divertor components for ITER.

Divetor component is the necessary ways for tokamak discharge in the process of controlling impurities and fuel recycling; exhaust heat and particle flow and helium ash from the center of the plasma, which also are the most critical components of ITER device.

The design specifications of tungsten copper tube type structural component are to withstand high thermal loads irradiation of 5000 10MW / m2 and 300 20MW / m2. However, since the thermal expansion coefficient and elastic modulus with greatly difference between tungsten material and tungsten copper alloy heat sink materials, the surface of tungsten copper will in higher thermal stress when it in the process of preparation and application. So tungsten copper tube type components is too difficult to developing.

The test module through the 5000 series of 10MW / m2 and 1000 20MW / m2 heat load cycle electron beam irradiation, exceeding the requirements of ITER. Which approved the plasma tungsten copper divertor’s advanced technology development. ITER Director-General Bernard Bigot be given due recognition and appreciation.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

5 Companies Fined More Than 3.5 Million Yuan, WO3 Desulfurization Catalyst Reduces Acid Rain

- Details

- Category: Tungsten's News

- Published on Wednesday, 06 July 2016 17:53

- Written by chunyan

- Hits: 664

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com