Will Apple be Next Nokia?

- Details

- Category: Tungsten's News

- Published on Tuesday, 26 July 2016 09:55

- Written by pure-tungsten

- Hits: 578

On July 7, Counterpoint Technology, a market research institute, released its research about smart phone market share of May. It showed that Apple only accounts for 10.8%, which is 1.2% decrease compared with May, 2015 and fell to fifth. On the contrast, China domestic smart phones, the four largest brands, Huawei, Vivo, Oppo and Xiaomi, have been increasing and the percentage is 53%. Among the data, Huawei ranked first with 17.3%, and Oppo 11% with a double going up.

Time goes back. In April, Apple released last quarter financial report. iPhone sales volume had declined as the first time in its sales history. So is its revenue, which is going down 13%, and 33% compared with the first quarter in 2015. After that, Apple promotes its iPhone SE with lower value of USD500.00, in order to interest the small screen users. No doubt, this type of iPhone has been the most obscure products of Apple these years. With a respect, it may run into the rural market. However, it may still lose with the competition of Vivo and Oppo. Even Citibank has lowered down its expectation of the third and fourth quarter financial report, and predicts that iPhone change time will last 30 to 36 months.

After those not so good reports of Apple, will it be next Nokia? It may and may not. If iPhone can effectively grasp the chance of phone change time and increase its quality, including its broken sapphire screen, which is growing in tungsten crucible in thermal field, then it may change its unfavorable situation. Surely, China domestic brands are also improving their quality better and better, so that their competition ability will be stronger. In order to increase their screen quality, the crucible should be pure enough, which is over 99.95%, for assurance of the quality of sapphire. Chinatungsten has been producing tungsten crucible over 20 years, its purity and quality can meet the requirement of producing out high-quality sapphire. Then it could be a power to support the hard ware parts of phones.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Standardization Technical Committee of Rare Earth Visited Japan and Korea Promote Development of Tungsten Heater

- Details

- Category: Tungsten's News

- Published on Monday, 25 July 2016 12:04

- Written by xuejiao

- Hits: 598

During June 10 to 16 in 2016, Ma unzhen, the Chairman of the Standardization Technical Committee of Rare Earth, and the Secretary, Gao Lan, and technologist Shen Guodi visited Japan and Republic of Korea. They communicated with leaders of the related standards departments, technology organization experts and some related representative of enterprises in Japan and Republic of Korea. In addition, they also attend “International Rare Earth Applications Forum” held in Westin hotel of Hokkaido.

During June 10 to 16 in 2016, Ma unzhen, the Chairman of the Standardization Technical Committee of Rare Earth, and the Secretary, Gao Lan, and technologist Shen Guodi visited Japan and Republic of Korea. They communicated with leaders of the related standards departments, technology organization experts and some related representative of enterprises in Japan and Republic of Korea. In addition, they also attend “International Rare Earth Applications Forum” held in Westin hotel of Hokkaido.

On June 11, 2016, the Japanese representative organized a special symposium of ISO (International Organization for Standardization). During the discussion, the Japanese representative expressed that as a big country of the application of rare earth, Japan hoped to cooperate with china in the field of international standardization, and emphasized the rare earth industry is crucial to Japan, Japan would attach great importance to the work of international standardization of rare earth.

Three representatives of China also communicated with a senior research fellow and two experts in Republic of Korea. They talked more about the technology of rare earth production, which would be conducive to the production of tungsten heater and other rare earth industry. After the talks, South Korean experts arranged a scene visit, detailing introduced the circumstances of their laboratory equipment. From the aspect of their test equipment, South Korea is fully equipped with the ability to participate in international standard testing. What’s more, South Korea experts agreed with our counterparts domestic enterprises in the rare earth standard.

The delegations also intuitively understood that the stuff and equipments situation of two countries for international standardization rare earth, which enhanced the confidence of international standardization work. The success of the exchange creates a good start to promote wolfram heater and other rare international standardization work. Moreover, China also learned advanced production technology from the two countries in this visit, which would help to improve the productivity and quality of the tungsten heater.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

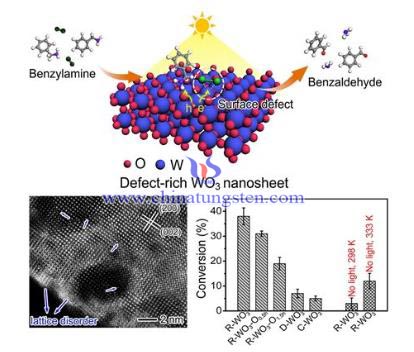

Defect-Rich Tungsten Trioxide Nanosheet Photocatalyst

- Details

- Category: Tungsten's News

- Published on Friday, 22 July 2016 17:47

- Written by chunyan

- Hits: 707

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

WO3 Catalytic Fuel Cell Vehicle Eases Global Warming

- Details

- Category: Tungsten's News

- Published on Friday, 22 July 2016 17:50

- Written by chunyan

- Hits: 705

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

"Made In China 2025" Promotes the Development of Tungsten Heater

- Details

- Category: Tungsten's News

- Published on Friday, 22 July 2016 15:16

- Written by xuejiao

- Hits: 590

As the first decade guideline of "three-step" strategy for construction of manufacturing power of China, "Made In China 2025" depicts a path for Chinese manufacturing from large to strong, which has been gained high-level attention by Communist Party of China (CPC). In early July 2015, the State Council set up national manufacturing power construction leading group, and the vice-premier Ma Kai is the group leader, and there are more than 20 government departments involved in this group. This group has held the third meeting and established a consultative committee for construction strategy of national manufacturing power, and builds up intersectoral links joint-action mechanism and actively mobilizes multi-power and enthusiasm.

Over the past year, for the implementation of the "Made in China 2025", the government mainly carried out three aspects. Firstly, the government prepared and issued the "1 + X" plan. Secondly, the government formulated a number of supporting policies. CBRC revised the "Commercial Bank M & A Loan Risk Management Guidelines" to encourage the support of commercial banks to manufacturing concern. It would work with the Ministry of Industry and Information Technology of the People’s Republic of China to further improve the financing guarantee system. The introduction of these supporting policies, mainly in order to provide the reasonable support for necessary innovation and development for manufacturing.

The third is to strengthen the guidance of local, promote development of regional differences. Some effects and implementation of policies and the major projects has been initially apparent. For example, “Enterprise R & D Expenses Plus Deduction Policy” further stimulates industrial enterprises, especially SMEs (Small and Medium Enterprises) innovation and dynamic development. Future development of "Made in China 2025" will be more perfect, be more conducive to long-term development of business volume, so that it will greatly facilitate the tungsten heater and other tungsten enterprises development.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com