Tungsten Carbide Industry Being Developed Deep Processing Tools Area

- Details

- Category: Tungsten's News

- Published on Friday, 26 August 2016 13:42

- Written by tang

- Hits: 754

Metal machinery manufacturing, machining is the most basic and reliable means of precision machining, mechanical, electrical, electronic and other modern industrial sector plays an important role. Machining technology development, the most recent history is the history of the development of the tool material. The new tool materials can greatly improve cutting production rate, improve processing accuracy, surface quality and expand the processing areas, reduce tool consumption, access to a huge economic benefits. The new tool materials for the development of machinery manufacturing plays a huge role in promoting. Therefore, the development, promotion and use of new materials is an important part of the new machinery manufacturing technology revolution.

Tungsten carbide is a new information tool, due to its high hardness, wear resistance and compressive strength, with more chaos chemical resistance, adhesion and heat resistance, excellent performance, and its tools high hardness materials cutting efficiency 5-10 times high speed steel cutting tools and machining speed steel cutting tools can not be processed, and therefore the tool data, according to a large proportion.

Meet the needs of modern science and technology development, to the precision of the direction, to enter since the seventies, in modern machining, cutting tools with carbide cutting inserts dimensional accuracy remarkable progress, therefore, carbide production manufacturers are constantly advances its product precision. For example, in some developed countries have phased out the U grade carbide precision. Many Carbide Die size has reached micron level precision, and even some have reached the end of ultrafine meter level.

Adaptation requirements produce sophisticated products, better technology and production equipment. Late sixties introduced carbide produced in the field of hot isostatic pressing, and seventies migration to Carbide production in the field of spray-drying technique, cemented carbide production process are a big step forward, In recent years, low-pressure hot isostatic clean burning equipment and technology to make carbide products density close to the theoretical value of up to 99.999%, significantly advances the quality of products.

In order to improve processing efficiency and adapt to the new requirements of automated machine tools, we developed a number of new carbide, such as ultra-fine fine carbide, gradient cemented carbide, carbide duplex, self-lubricating alloy, nanoscale hard alloy, super-hard coating layer of hard alloy. Meanwhile tungsten carbide industry forward depth processing tool areas.

Tungsten carbide consumption in our country although Unfettered unfolded after emerging industry, but carried out rapidly, especially after the reform and opening up, the emergence of independent growing trend. Currently, carbide production in the country has been in the forefront of the world, the product brands, models also more fully, and has many product quality has reached the international advanced level, the output value and profits to grow steadily.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Trioxide in Photoelectric Field

- Details

- Category: Tungsten's News

- Published on Wednesday, 24 August 2016 10:04

- Written by chunyan

- Hits: 717

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

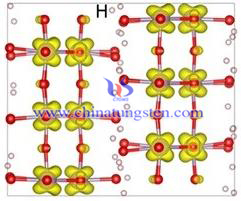

Hydrogen Doped WO3 Plasmon Nanostructure

- Details

- Category: Tungsten's News

- Published on Thursday, 18 August 2016 11:36

- Written by chunyan

- Hits: 673

Since the importance of plasmon nanostructure in areas of nano photonics, biochemical sensing and medical diagnostics ect., manufacturing technology of plasma nanostructure has recently caused a lot focus for people researching. By controlling the size, shape and composition of plasma nanostructures, one can adjust its optical and electrical properties over a wide range. With the advent of nanoscience and nanotechnology, plasmon nanostructure has developed rapidly, the coherent oscillations of free electron has on the incident light will cause localized surface plasmon resonance (LSPR) in the structure; besides, this phenomenon is associated with optical near field zoom, and has been used in surface-enhanced Raman scattering (SERS), biological testing and energy storage and conversion and other aspects.

Since the importance of plasmon nanostructure in areas of nano photonics, biochemical sensing and medical diagnostics ect., manufacturing technology of plasma nanostructure has recently caused a lot focus for people researching. By controlling the size, shape and composition of plasma nanostructures, one can adjust its optical and electrical properties over a wide range. With the advent of nanoscience and nanotechnology, plasmon nanostructure has developed rapidly, the coherent oscillations of free electron has on the incident light will cause localized surface plasmon resonance (LSPR) in the structure; besides, this phenomenon is associated with optical near field zoom, and has been used in surface-enhanced Raman scattering (SERS), biological testing and energy storage and conversion and other aspects.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Equipment Solve Partial Wearing Problem

- Details

- Category: Tungsten's News

- Published on Monday, 22 August 2016 18:08

- Written by tang

- Hits: 518

Recently, the Yumen Oilfield Oil Production Plant oil duck children gorge team technical team leader Li Ning serious stare duck K1-10 wellsite conceal his face is delighted: "Since the use of this device, which I often need surgery well made no been ill, and now we can rest assured that in other to promote the use of the well. "

Duck children Gorge Reservoir Oil Production Plant complex geological structure, oil prone eccentric wear phenomenon. Previously, in order to prevent eccentric wear caused by oil bar broken off, oil wells team technical team to install anti-eccentric wear equipment. Employees also use the opportunity well underground work, from a downhole sucker rod section hoop, pump, tubing head thread and other downhole equipment to conduct a comprehensive inspection. However, anti-bias milling equipment still could not really solve the oil well pumping unit section hoop, threaded tubing head appeared eccentric wear problems. Especially in recent years duck children gorge horizontal wells increased, accounting for 70% of new drilling, pump hanging in 1900-2100 meters, displacement of up to 200 meters above the bottom, resulting in serious eccentric wear rod, using up more than 120 days will be break off occurs.

Since the beginning of this year, for the control of oil wells due to the occurrence of breaking off caused by multiple rounds lie well, duck child Gap oil technology group team counting finer benefits account. And repeated the repair and replacement of equipment, is bound to increase costs, affecting the normal production wells.

After then, the duck child Gap oil oil drilling teams to coordinate the Institute of plant and machinery, and the geological structure of the reservoir section hoop, tubing head material such as a comprehensive analysis of the carbide homemade device. Grindability in the well area installed in the underground ring segment added centralizer re-optimize the portfolio by carbide strength and good finish, reduced wear resistance. Duck child Gap oil production crew through an annular segment downhole added centralizer re-optimize the adjustment, prevent breaking off the hoop section, extending well exemption period.

Li Ning said: "We selected four sections hoop and tubing head screw serious eccentric wear wells may be used, the effects were good, especially the duck duck K1-10 and K1-15 well well, since after the equipment installed on the carbide never happened broken off. Tungsten carbide equipment not only solves the problem of partial wear well, but also reduces the cost of repair of oil wells. " Next, duck children gorge on oil production crew will be easy to promote the use of eccentric wear wells carbide devices.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

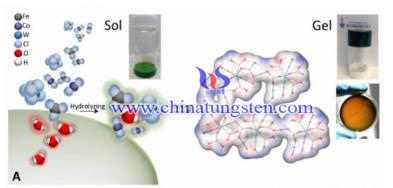

WO3 Contained Ultra-Low Overpotential Oxygen Evolution Catalyst

- Details

- Category: Tungsten's News

- Published on Tuesday, 16 August 2016 16:21

- Written by chunyan

- Hits: 702

Hydrogen is an excellent energy carrier, and the way of solar-powered electrolysis of water to produce hydrogen is an effective method for energy storage. In the traditional SPEWE, since the high oxygen evolution potential, oxygen will cause serious dissolution to the carrier of carbon; in the oxygen evolution reaction process, dissolution and passivation of anode will occur and to shorten its live when electrode with high oxygen evolution overpotential working under the high potential. The presence of multiple high-energy intermediate state makes the oxygen evolution reaction one of the most difficult steps in the electrolyzed water. Thus, the preparation of ultra-low overpotential oxygen evolution catalyst will help to achieve efficient electrolysis of water.

Hydrogen is an excellent energy carrier, and the way of solar-powered electrolysis of water to produce hydrogen is an effective method for energy storage. In the traditional SPEWE, since the high oxygen evolution potential, oxygen will cause serious dissolution to the carrier of carbon; in the oxygen evolution reaction process, dissolution and passivation of anode will occur and to shorten its live when electrode with high oxygen evolution overpotential working under the high potential. The presence of multiple high-energy intermediate state makes the oxygen evolution reaction one of the most difficult steps in the electrolyzed water. Thus, the preparation of ultra-low overpotential oxygen evolution catalyst will help to achieve efficient electrolysis of water.| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com