The Greenest Shanghai Tower May Use Tungsten Trioxide

- Details

- Category: Tungsten's News

- Published on Monday, 05 September 2016 11:15

- Written by chunyan

- Hits: 677

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Breakthrough of Chinese Scientists - Let Liquid Metal Machine Run, Jump

- Details

- Category: Tungsten's News

- Published on Friday, 02 September 2016 17:42

- Written by tang

- Hits: 960

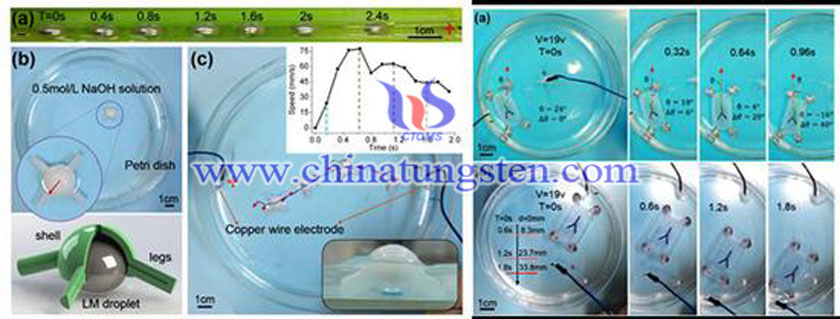

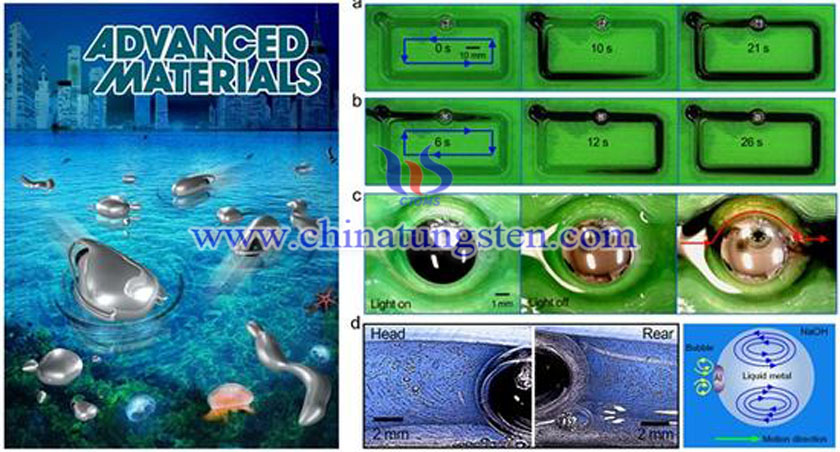

In 1991, the movie "Terminator 2" appears in a powerful robot T-1000, the use of liquid metal to create a robot no matter how much harm can be met with an instant automatic recovery, and even can change the body shape and facial appearance. This deformation robot scientist has always been one of the goals, and now, a study by Chinese scientists in the field of liquid metal eligible for a breakthrough in the long road of research and a small step forward. New research allow liquid metal machine can "run" can "jump".

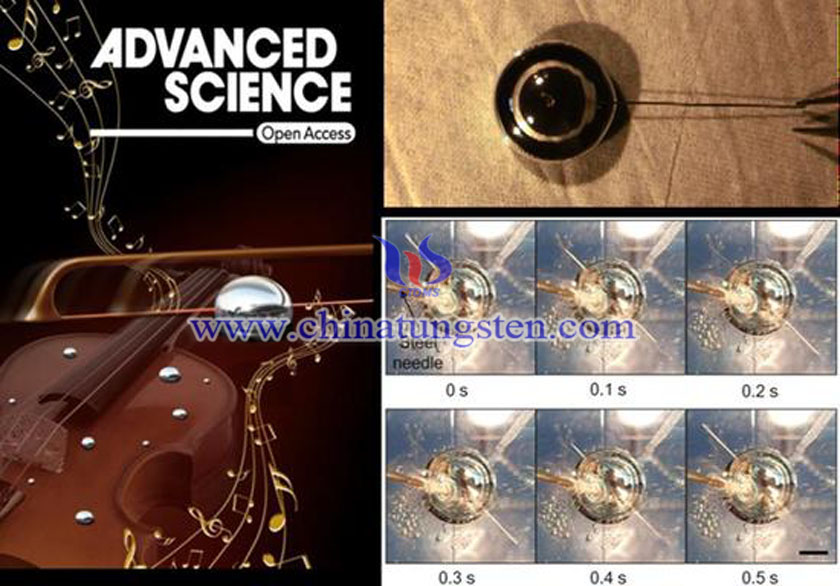

Liu Jing team research group reported an unusual unique self-oscillation effect of liquid metal solid-liquid combination machine: when the tungsten copper wire touches treated aluminum-containing liquid metal, tungsten copper wire are quickly swallowed by the liquid metal, and then made a long shuttle back and forth movement of the liquid metal in the body, like playing the violin string music in general.

Tungsten copper wire with heat ablation resistance, high strength, electrical conductivity and other characteristics.

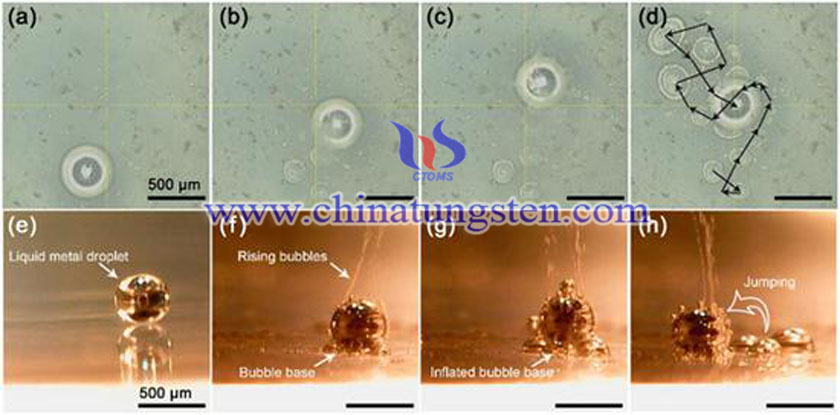

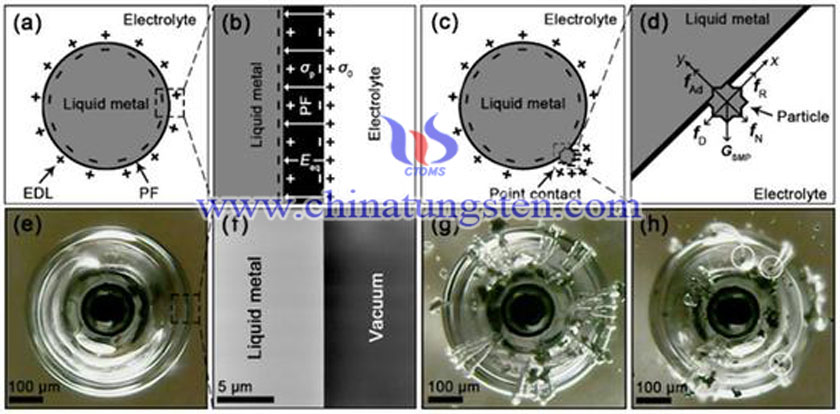

The authors found that a class of interesting liquid metal jump behavior: There is added to the discharge of solid metal particles (tungsten, nickel, copper, iron, etc.) solution system of metal droplets, the original stationary metal droplets began to beat up and leaving a string of cake in the bottom of the container "footprint."

Research revealed that the surface of the metal particles and liquid metal point contact occurs when the electric field strength at the interface significantly enhanced, as well as in the solution within the electrolysis hydrogen production, hydrogen bubbles are formed in the substrate continues to grow adsorption "gas spring", which droplets jump provide thrust. One of the factors leading to the electric field polarization between the liquid metal from the metal particles with solid potential difference that is galvanic effect; the other reason is that the solid - liquid material microstructure differences between the interface will lead to charge accumulation, sparking tip discharge effect.

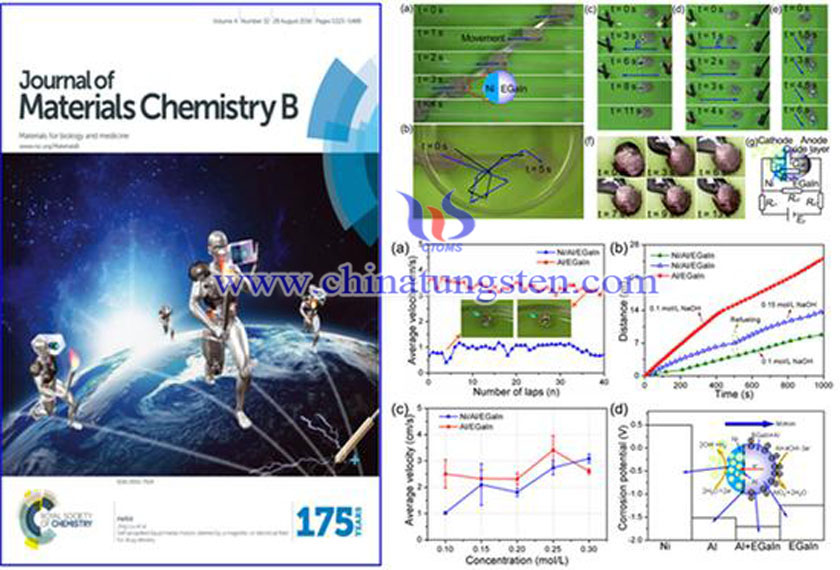

Research team by a plating method in the liquid metal surface mount ferromagnetic nickel layer, thereby realizing flexible control of the machine in an external magnetic or electric field and verify its potential value in terms of drug delivery. Beyond the random motion of the liquid metal type machine it is that the magnetic solid-liquid combination can be achieved from the machine stop motion, steering and acceleration of complex behavior.

Furthermore, the team also developed a kind of flexible deformable "wheels" driven miniature vehicle, its body is made of plastic and metal droplets through a combination of 3D printing. In the electric field, the liquid metal "wheel" can rotate deformed, and then drive the vehicle travels, and even accelerate the realization of more complex motion.

Liu Jing study team found that in the electrolyte, a liquid gallium based alloy, after "swallowing" Aluminum as food or fuel, can actually deformed shape long high-speed motion machine to achieve without external power autonomy movement.

In recent years, Liu Jing team has been working to promote joint industry liquid metal industrial applications. She said: We have the opportunity to study in the liquid metal in the world to go ahead, but can not lag behind in terms of industry, we need to seize the historic opportunity to help build our country into a world-class liquid metal valley.

| Tungsten Copper Supplier: Chinatungsten Online tungsten-copper.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Warhead Enhances Missile Lethality Greatly

- Details

- Category: Tungsten's News

- Published on Thursday, 01 September 2016 20:45

- Written by TungstenAlloy

- Hits: 1355

It is reported that China has created the world's first surface-to-air missile( also known as ahead) to shoot down enemy planes, which is researched and developed by themselves, and the combat capability has been formed.

The Red Flag – surface-to-air missile mainly used in the fight against all types of aviation raid target, is the long-range air defense equipment in our military field; Red Flag 6 missile is a new generation of terminal defense weapons, anti-aircraft guns and missiles with high accuracy the high rate of fire is achieved the end of the air defense interceptor. Warhead takes significant effects on the missile lethality.

Due to the high strength, high temperature resistance, high crush resistance, high hardness, non-toxic environmental protection and other properties, tungsten alloy material becomes more and more popular for the military field using as tungsten alloy warhead and tungsten alloy ahead. It should be made into the shape of sphere, cube and pin, working as prefabricated fragments.

The size of tungsten alloy cubes for ahead could be customized as per clients’ drawing or design.

Waxing and binding makes the spheres distributing much uniform in the warhead. The binder would be melted in the high temperature.

Tungsten alloy spheres or tungsten alloy pins for ahead left as its high temperature resistance, so as to enhance missile performance.

If there is any interest, please email to sales@chinatungsten.com for more details.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Accelerates Nuclear Fusion Reactor Research

- Details

- Category: Tungsten's News

- Published on Thursday, 01 September 2016 21:49

- Written by TungstenAlloy

- Hits: 1258

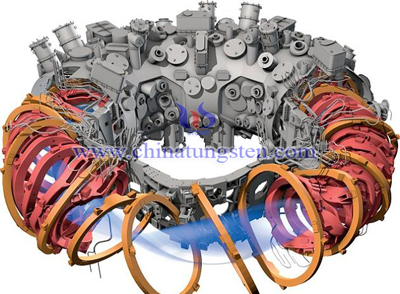

It is reported from the overseas that US government scientists are creating a "jar stars" replicate the way the sun and other stars to generate energy through nuclear fusion on earth. If successful, the human beings will get inexhaustible energy, and no longer need to rely on fossil fuels to produce the electricity. That would be pretty wonderful.

With the continuous efforts of the international community, the physical feasibility of nuclear fusion reactor has been confirmed, including Tokamak type magnetic confinement controlled nuclear fusion research, the progress in this field has been fastest among the most mature technology.

Princeton Plasma Laboratory, US Department of Energy (abbreviated PPPL) physicists recently in the journal Nuclear Fusion published a paper which showed their research of new generation of nuclear fusion equipment plans. PPPL laboratory and England Kalam already have a spherical Tokamak. All these will provide ideas to help scientists design a new type of fusion device, as so to build further by a commercial fusion power plant generating electricity.

During researches, the selection of material has always been a key factor to whether the fusion energy could be developed or not. In fusion materials, it is a class of very important materials is plasma material, also known as coating materials. Tungsten alloy has been proved in research and development owing superior physical and chemical properties in a high-energy level, such as high melting point, high density, high density, low vapor pressure, good thermal conductivity and high strength, also stability enough not form a hydride with hydrogen. Therefore, tungsten alloy becomes a very rare coating material applied on the high-temperature flux components.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Small Neck Carbide End Mill Increasingly Wide Application Areas

- Details

- Category: Tungsten's News

- Published on Thursday, 01 September 2016 14:25

- Written by tang

- Hits: 723

Carbide end mill launched smaller neck diameter models, and expand the range of applications and versatility. When machining complex parts, such as the aerospace industry, medical industry and general machining industry artifacts, these latest tools can be used after a larger angle.

Smaller neck size makes it easier to process using complex holder holding a workpiece, and allows users to fully play workability four and five axis machine tools. Neck size has been fully optimized, not only to maintain the rigidity of the tool, but also with the standard tool holder system has perfect compatibility. In addition, this tool also retained the ISO P M, S, and performance efficient processing of other materials group materials.

Carbide end mill with a high degree of stability and low deflection. This series of products in many applications also showed excellent value for money, and these latest models also makes advanced features of the product is enhanced.

Carbide end mill series, ranging in diameter from 3 mm to 20 mm, typically cutting length 2xD + 2 mm. Overhang length 3xDc. The series also includes a rounded nose type and 45o chamfer type products for cylindrical and Weldon shank type.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com