New Material Called Tungstenite Has Optical Applications

- Details

- Category: Tungsten Patents

- Published on Tuesday, 05 February 2013 14:26

- Hits: 2994

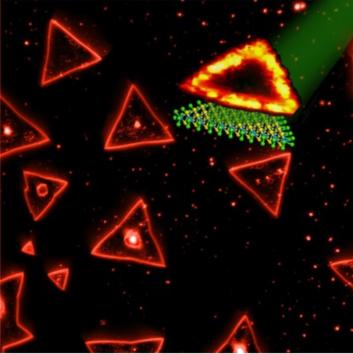

Single layers of tungsten disulfide create triangles that exhibit extraordinary photoluminescence at their edges, while the interior area does not. Credit: Terrones lab/Penn State University

A rare mineral called tungstenite has been formed into thin sheets with possible uses in technologies such as light detectors and lasers, U.S. researchers say.

Stacked in sheets with sulfur atoms, it forms tungsten disulfide in a honeycomb pattern of triangles that have been shown to have unusual light-emitting, or photoluminescent, properties, Penn State researchers reported Monday.

Photoluminescence occurs when a substance absorbs light at one wavelength and re-emits that light at a different wavelength, Penn State physics and material science Professor Mauricio Terrones said.

The "monolayer" of tungstenite and sulphur atoms photoluminesce at room temperature, he said, so "no special temperature requirements are needed for the material to exhibit this property."

The researchers said the material has many potential applications in the fields of optical light detection, the production of light-emitting diodes, and even laser technology.

"The images of the photoluminescence are beautiful; the triangles light up all around their edges like little holiday ornaments -- holiday ornaments with potentially transformative, long-term applications in nano-optics," study co-author Vincent H. Crespi said.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

U.S. Patent 2,883,571 Elmer Fridrich and Emmett Wiley's Tungsten Halogen Lamp

- Details

- Category: Tungsten Patents

- Published on Wednesday, 26 December 2012 09:33

- Hits: 4330

This patent, granted on 21 April 1959, is for the tungsten halogen lamp. The lamp in figure 1 (at top) shows what has become the typical configuration for these lamps. Figure 2, however, shows a low-voltage configuration that is less familiar. The low-voltage design played a role in a little known project in the early 1970s.

Trent West, Tungsten Rings and US Patent Law

- Details

- Category: Tungsten Patents

- Published on Friday, 21 December 2012 14:01

- Hits: 3778

If you have a tungsten carbide ring, you may own stolen goods. This is not to say you didn’t pay the asking price, but, there is a real possibility that whoever sold the ring didn’t pay dues to Trent West. There is an even greater chance that whoever made the ring did so using West’s designs.

Mr. West holds nine patents for tungsten carbide rings and his lawyer, Edward King of King & Kelleher, LLP7, says there’s another in the works that could be issued any day now.

It may seem shocking that someone could patent an idea as ancient and common as a ring. Mr. West did so because he invented a method of converting one of the hardest metals into shiny bands of jewelry, something he insisted had never been done.

“There were absolutely no tungsten carbide rings before I made them,” he declared, “unless it was something made for an industrial purpose.”

The idea was born when West, already a jeweler, saw a watch made of tungsten carbide. He identified an opportunity in the market and acted on it. West trademarked8 two brands, TREW TUNGSTEN® and PERMANENTLY POLISHED® and was very successful in selling his rings. But these days, instead of being busy with production and expansion, he is largely focused on lawsuits against those who infringe upon his patents.

King said there are other methods of making this jewelry (besides those developed by West), but they’re expensive. Trent patented the only commercially viable way of making tungsten carbide rings.

Given that fact, West and his lawyer believe that everything currently on the market infringes one or more of West’s ring patents, which cover technical details spanning from tungsten carbide content to the insertion of stones and softer metals.

Over the last decade, tungsten carbide rings have grown increasingly popular and are now estimated to represent over 20 percent of the wedding band market. High prices for precious metals and a weak global economy could promote further growth. Yet, the benefits of being the inventor and patent holder have dwindled.

Consumers can find an array of tungsten carbide rings from a wide range of sources. According to Mr. West and details outlined in his lawsuits, most are are either acting illegally or unethically. Companies attempt to get around the legal protection of the West patents in numerous ways. The lawsuit against JCPenney9, a major US retailer, highlights one.

It is basically illegal to make, sell, offer for sale or import products covered by West’s patents. However, JCPenney eluded liability for their infringement using a patent loophole that requires an importer be held liable before taking legal action against a retailer.

JCPenney was not directly importing the tungsten carbide rings sold in its stores. Therefore, by selling jewelry known to be patented, JCPenney is technically acting unethically as opposed to violating the law.

Though West sued the wrong party, the case exposed JCPenny’s supplier, C & C Jewelry Manufacturing, against whom a lawsuit is now pending.

Mr. West has filed over a dozen lawsuits including some against well known companies such as Target and Helzberg Diamonds.

With the exception of JCPenney those cases have resulted in the companies either taking licenses or they have gone out of business King said.

Frederick Goldman and Jewelry Innovations10 are examples of companies granted licenses, which involve paying royalties to West.

Another means of attempting to dodge the West ring patents is by altering details such as tungsten carbide content in a given piece of jewelry.

West has a patent that specifies protection for rings at least 50 percent but not exceeding 85 percent tungsten carbide. He has another that protects rings that are predominantly tungsten carbide.

If someone wants to make a ring with 30 percent tungsten carbide content, they can raise an argument as to whether they are committing patent infringement, Mr. King explained.

Retailers and importers weren’t able to slight West on their own. He blames the Chinese for running him out of business.

West spent three years and a lot of money developing, patenting, and bringing his rings to market. He opened a production facility where he says he had 17 full-time employees. Then, around 2003-04, the copying started.

West began seeing products made by Chinese copy cats. Then, by around 2005, the Chinese opened factories and started flooding the market with cheap patent infringing rings.

“I had to close my factory and let my employees go,” he said. “The [tungsten carbide ring] market has shifted to a commodity. I cannot survive in a commodity.”

“The Chinese had the advantages of cheaper raw materials and cheaper labor, he explained. “They could produce a finished ring for what I was paying for a raw blank.”

Most consumers have likely never heard of Trent West and most probably never will. Nearly all the tungsten carbide rings currently on the market come from China. But, West continues to fight for his dues. By way of his lawsuits, he aims to create an environment where he can obtains royalties from select licensed sellers of tungsten carbide rings.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

ITC Takes up Tungsten Patent Dispute

- Details

- Category: Tungsten Patents

- Published on Friday, 21 December 2012 14:16

- Hits: 3380

LSI and Agere are merged business partners who jointly own a patent on tungsten-metallised semiconductor circuits. They allege that the named respondents have participated in the importation of copied tungsten-metallised semiconductors into the US, which violates section 337 of the 1930 Tariff Act.

Among those named are Taiwanese firms ProMOS Technologies and Powerchip Semiconductor Corporation, plus Japan's Elpida Memory, Inc. The patent in question – US 5,227,335 – relates to a method of treating semiconductors common to miniature electronic devices, in order to improve their efficiency. In their complaint, LSI and Agere have requested the ITC to serve cease-and-desist notices to the 18 firms, prohibiting the 'importation, sale, offer for sale, advertising, or the soliciting of sale' of the relevant circuits.

LSI and Agere's case highlights the growing importance of the ITC to the US patent landscape. An independent, quasi-judicial body set up to target trade injury to the US, the commission has established itself as a powerful, alternative means of tackling infringement.

While it is incumbent on Federal District Courts to satisfy higher statutory requirements – based on their personal jurisdictions over alleged infringers – the ITC has national, in rem jurisdiction over all products imported to the US. This jurisdiction over objects means that the ITC's statutory requirements are satisfied by the very presence of infringing products on US soil. If the ITC determines the presence of such products, it is authorised to block them.

Neither LSI, Agere nor their respondents have commented on the case so far.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

American National Carbide Announces the Launch of its Synergy™ Line of Carbide Inserts for High-Temp Alloys

- Details

- Category: Tungsten Patents

- Published on Friday, 21 December 2012 17:20

- Hits: 3970

Since 1970 American National Carbide (ANC) has been a leading manufacturer of quality tungsten carbide products, delivering carbide value to the metalworking, oil and gas, and wood processing industries. Always committed to innovation, ANC delivers again with its new Synergy™ line of indexable carbide turning inserts. Synergy’s state of the art carbide substrate, enhanced by the latest nano coating technology, is engineered to perform at the elevated temperatures that are common when machining superalloys. Synergy’s innovative design and proprietary post-coating treatment ensure optimal chip control while reducing cutting forces. From roughing to finishing, Synergy™ offers a total high temperature solution:

Functional 100° roughing corner for enhanced productivity

Coolant flow channel for efficient temperature regulation

Positive ground land to reduce cutting forces

Multiple obstructions for optimal chip control

Helical land angle to resist DOC notching

Mechanical post-treatment to reduce friction

Post-coating surface grind for maximum stability

Wide chip breaking range

SG style for General Purpose

SF Style for Finishing

SR Style for Roughing

“High-temperature alloys have finally met their match. Merging the latest technology in engineering, metallurgy, coating, and post-treatment, we’ve created Synergy™ - a line of advanced indexable carbide inserts for the toughest challenges...”

ANC prides itself in its flexibility to work closely with customers to design and manufacture carbide products for virtually any application. The current launch of Synergy™ carbide inserts attests to the level of innovation that can occur when a synergetic relationship exists between a manufacturer and its customers. As a vertically integrated manufacturer, ANC produces its raw materials and press tooling in house. In addition to its 50 standard carbide grades, ANC can formulate new grades to exact specifications. ANC’s tooling design and production capabilities allow the manufacturer to create complex geometries without issue. ANC utilizes ISO-compliant metallurgical testing on all of its raw materials, grade powders and sintered products in order to ensure conformity with critical specifications.

ANC has serviced the metalworking industry worldwide for more than forty years through the manufacture of tungsten carbide indexable inserts for turning, boring, milling, parting, threading, and grooving applications. ANC has a network of sales representatives strategically positioned to provide service globally, and its highly-trained in house sales and technical support teams assist customers with any questions they may have regarding Synergy™ or any other product or service. ANC has a proud history of excellent customer service and support, and this dedication to customers’ needs continues to be a company trademark, as ANC invites new challenges to innovate the quality of its products and services.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Trent West Settles Tungsten Carbide Patent Suit with Stuller and Quality Gold

- Details

- Category: Tungsten Patents

- Published on Wednesday, 26 December 2012 09:55

- Hits: 3449

Trent West, owner of nine patents related to the concept and manufacture of Tungsten Carbide rings in the United States, has come to a settlement agreement with Stuller Inc. and Quality Gold.

As part of the settlement agreement, Stuller has obtained a license to sell Tungsten Carbide rings to its customer base of independent retailers throughout the United States. With this license, Stuller joins Frederick Goldman Inc., Benchmark, Jewelry Innovations and Fable Jewelry Company as the only legally authorized sellers of Tungsten Carbide rings protected by West’s nine patents. Quality Gold of Fairfield, Ohio, has agreed to exit this business and will not sell Tungsten Carbide rings after March 7, 2013.

“We are pleased to have settled this case with Stuller and Quality Gold. We believe the final agreement was fair to all parties involved,” stated Edward King, the attorney representing Trent West. “This agreement is yet another major development in recognizing the validity of Trent West’s patents and his ability to enforce the rights protected by his patents.”

A number of settlements have been reached with both manufacturers and retailers of Tungsten Carbide rings. West will continue to enforce his patents and exercise his rights against other manufacturers and retailers infringing on patent numbers: 6,062,045, 6,553,667, 6,990,736, 6,928,734, 6,993,842, 7,032,314, 7,076,972, 7,761,996 and 8,061,033.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

REMco Tungsten Tips for Barmac Crushers

- Details

- Category: Tungsten Patents

- Published on Wednesday, 26 December 2012 10:25

- Hits: 3224

The Barmac tungsten tip with its unique high ridge, supporting flange and threaded tab was invented and patented by REMco in 1990. Subsequently the patents were sold to Svedala in 1993. Now the original US patent, # 4,940,188, has expired and REMco can supply all versions of this part.

REMco offers a wide variety of tips for Barmac VSI machines. They offer many different grades of tungsten inserts to ensure correct application and the longest wear life for the tips without breakage. Different from OEM tips, all of REMco´s are cast steel (not cast iron) to provide the best possible support to the tungsten insert and thus contribute to longer wear life.

Different grades of tungsten tips identified by color:

Green Tungsten Tips

This grade has broad popularity and it is designed for long life with resistance to breakage for feed sizes below 1 1/2" (40 mm) and for slow to medium rotor speeds.

White Tungsten Tips

This is a unique tungsten grade supplied only by REMco. It provides impact resistance with feed sizes to 3” (75 mm) and all rotor speeds.

Black Tungsten Tips

This grade has the highest resistance to chipping and cracking of the tungsten insert. It is recommended for very coarse and boney feeds.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

PC Version: Tungsten News & Tungsten Prices: http://news.chinatungsten.com

3G Version :Tungsten News & Tungsten Prices : http://3g.chinatungsten.com

WML Version:Tungsten News & Tungsten Prices: http://m.chinatungsten.com

Veined Cutting Tool - Precorp Assigned Patent

- Details

- Category: Tungsten Patents

- Published on Tuesday, 08 January 2013 14:08

- Hits: 1961

ALEXANDRIA, Va., Jan. 7 -- Precorp, Spanish Fork, Utah, has been assigned a patent (8,342,780) developed by Richard M. Garrick, Woodland Hills, Utah, and John A. Bunting, Provo, Utah, for "shielded PCD or PCBN cutting tools."

The abstract of the patent published by the U.S. Patent and Trademark Office states: "A veined cutting tool for producing holes in various materials is disclosed. The veined cutting tool includes a tungsten carbide body using a sintered abrasive particulate such as diamond (PCD) or Cubic Boron Nitrite (PCBN). The cutting tool shields a portion of the PCD or PCBN edge on the cutting side to reduce the overall length of the exposed PCD or PCBN to prevent the cutting edge from chipping and increase the service life of the cutting tool."

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

The Use of Molybdenum and Tungsten in Crucibles

- Details

- Category: Tungsten Patents

- Published on Thursday, 10 January 2013 09:33

- Hits: 3044

Tungsten and Molybdenum Crucibles

Formed tungsten and molybdenum crucibles perform extremely well in Heat Exchanger Method (HEM) process and are suitable for melting and solidifying of single crystals. Formed crucibles from PLANSEE have thin walls and exhibit superior creep resistance.

Pressed-sintered crucibles from PLANSEE are mainly used in the Kyropolous process for the production of sapphire. When sapphire is easily extracted, better yield and improved quality of sapphire can be realized. PLANSEE’s tungsten and molybdenum-based crucibles are heat-resistant and feature a smooth surface, which make them durable and cost-effective. They are also resistant to corrosion and have a high material density.

PLANSEE’s pressed-sintered crucibles are made from tungsten or molybdenum and have a surface roughness of below 0.8 µm. when the crucible’s surface is rough, the sapphire cannot be easily extracted and this tends to damage the crystal. Besides, the crucible also gets damaged in the process. The ultra-smooth crucibles from PLANSEE eliminate these issues. Sapphire manufacturers can benefit from this product as it eliminates complex and costly processes. In addition, the smooth surface is resistant to corrosion induced by the aggressive melted sapphire. This feature extends the life of the reusable tungsten crucibles.

PLANSEE’s molybdenum crucibles are in huge demand. The reason attributed for this demand is molybdenum is quite complex to develop and involves thorough knowledge with respect to handling the material and setting up the machines. PLANSEE has the required expertise in meeting this demand. According to Heike Larcher, PLANSEE application group manager for Single Crystal Growing, the high-purity material does not contaminate the single crystal.

Conclusion

PLANSEE has extensive expertise in the field of powder metallurgy and develops high purity and high density crucibles that have uniform wall and base thicknesses, which are key prerequisites for attaining excellent creep resistance. Tungsten and molybdenum crucibles are developed in various dimensions. Many customers and major manufacturers across the globe have successfully utilized these crucibles. At PLANSEE, the input material for crucibles is produced in-house from the hot rolling mill, which is touted to be the largest hot rolling mill in the world for refractory metals. Here, massive tungsten and molybdenum sheets are developed which will allow the company to produce products in large dimensions and in huge quantities in the years to come.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Albert Browne Updates with Two Polar 78N Plus Cutters

- Details

- Category: Tungsten Patents

- Published on Wednesday, 16 January 2013 09:43

- Hits: 2907

Chemical indicator technology specialists Albert Browne will take delivery of two latest generation Polar 78N Plus guillotines in the first quarter of this year.

The Leicester company is the largest Polar 78 user in the UK with six machines running continuously eight hours a day. Five years ago the company completed its switch from EBA to Polar technology and this time round Albert Browne looked at two options, closely comparing Polar with a rival manufacturer.

The Leicester company is the largest Polar 78 user in the UK with six machines running continuously eight hours a day. Five years ago the company completed its switch from EBA to Polar technology and this time round Albert Browne looked at two options, closely comparing Polar with a rival manufacturer.

Said general manager Alan Charlton, ‘We normally replace equipment every seven years but the guillotines have been so reliable and productive they have been kept on almost double that time. We use our guillotines intensively so they have to be robust; the performance of the Polars to date was convincing when we came to upgrade.’

The buying decision was based on research by production manager Stephen Brown who said, ‘These new generation Polar 78N Plus guillotines, equipped with air tables, will give us an extra 15 per cent productivity due to the improved cycle time, cut to cut. It was that and the minimal amount of maintenance and repairs required on our previous Polar machines that provided the business case for sticking with Polar. Our operators look forward to using the new guillotines, featuring the latest 18.5-inch touchscreen technology and graphical programming automation.’

Both machines will operate with tungsten carbide knives because the company needs a robust cut as it switches regularly between newsprint and polypropylene laminates. The tungsten blades give a ten times improvement on knife life for these products over HSS blades.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Benelli Introduces the Lightning-Fast Vinci Speed-Bolt Shotgun

- Details

- Category: Tungsten Patents

- Published on Wednesday, 16 January 2013 13:53

- Hits: 2992

ACCOKEEK, MD - The Benelli designers have taken the tried and true features of that rugged, bird- and target-busting Vinci and incorporated them into a new version called the Vinci “Speed-Bolt.”

Combining these features provide the Vinci Speed-Bolt with all the attributes that tactical shooters seek—superior balance, lightweight, reduced recoil and minimal muzzle climb.

This is what Benelli calls Practical Speed Performance or “PSP,” which is the real performance timeline of “speed,” and includes quickness of mount, immediate target acquisition, fast fire, instant recovery and rapid, reliable follow-up shots.

At the heart of the Vinci Speed-Bolt is the In-Line Inertia Driven System, utilizing Benelli’s new Speed-Bolt – a bolt inset with tungsten, designed for faster cycling and handling loads as light as one ounce—and that means less recoil and muzzle climb. Experienced tactical competition shooters appreciate and value less recoil and muzzle climb in terms of getting on target quicker after the first shot. The next shot can be taken quickly and efficiently, which is critical for scoring winning times.

“The tungsten inset featured in the Speed-Bolt of this new Vinci gives a definite advantage to the competitive shooter,” said Stephen McKelvain, Benelli USA’s VP of Marketing. “With the ability to recovery quicker and hit multiple targets faster, shaving even a fraction of a second can give the winning edge that every competitor desires.”

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Faster and Cheaper Process for Graphene in Li-ion Batteries

- Details

- Category: Tungsten Patents

- Published on Friday, 18 January 2013 09:54

- Hits: 2932

Over the last couple of years, research to improve lithium-ion (Li-ion) batteries have been turning to graphene, particularly after researchers at Northwestern University successfully sandwiched a layer of silicon between graphene sheets in the anodes of Li-ion batteries.

But most of the Li-ion battery work being done with graphene to date has depended on high-vacuum environments to create the layered material. Now Gurpreet Singh, a Kansas State University assistant professor of mechanical and nuclear engineering, is leading a team that's looking at faster and cheaper ways of synthesizing the material.

"We are exploring new methods for quick and cost-effective synthesis of two-dimensional materials for rechargeable battery applications," Singh said in a university press release.

The two-dimensional materials to which Singh refers includes not only graphene but also tungsten disulfide nanosheets. In his work with graphene, which was published in the journal Applied Materials & Interfaces (“Synthesis of Graphene Films by Rapid Heating and Quenching at Ambient Pressures and Their Electrochemical Characterization”),Singh’s team was able to create the graphene outside of a vacuum.

The graphene sheets were grown on copper and nickel foils by placing them in a furnace in which a mixture of argon, hydrogen and methane gases was carefully controlled. The researchers quickly heated and cooled the metal foils, forming the graphene films. The entire process apparently takes less than 30 minutes.

When the researchers then used the graphene films to fashion the negative electrode of a Li-ion battery, they discovered that graphene formed from the copper did not cycle lithium ions and had negligible capacity. However, the graphene electrode created from nickel had far superior performance to the copper version.

"We believe that this behavior occurs because sheets of graphene on nickel are relatively thick near the grain boundaries and stacked in a well-defined manner -- called Bernal Stacking -- which provides multiple sites for easy uptake and release of lithium ions as the battery is discharged and charged," Singh said in the release.

The second line of research that Singh and his team undertook with tungsten disulfide nanosheets involves conversion-reaction batteries. Conversion-reaction batteries are so named because the materials used in the batteries undergo a conversion reaction when in contact with lithium. A fair amount of work is ongoing to get a better handle on the nature of these conversion reactions, but in the meantime there’s a lot of excitement about the high-capacity capabilities of such batteries.

In the Kansas State research, which was published in the Journal of Physical Chemistry Letters (“Synthesis of Surface-Functionalized WS2 Nanosheets and Performance as Li-Ion Battery Anodes”), Singh and his team developed a process for separating bulk tungsten disulfide into two-dimensional crystals, only three atoms thick. When the material is applied to Li-ion batteries it stores and releases lithium ions in a completely different way from the graphene. When lithium comes in contact with the tungsten disulfide the materials undergo a conversion reaction leaving tungsten and lithium sulfide.

Despite all the new enthusiasm for conversion-reaction batteries, Singh concedes tungsten disulfide may not work for some potential applications of Li-ion batteries based on conversion reactions.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Hardide CVD Hard Coatings for Mechanical Face Seals

- Details

- Category: Tungsten Patents

- Published on Friday, 18 January 2013 10:16

- Hits: 3060

Introduction

Hardide coatings, an advanced surface coating company, manufactures Hardide chemical vapour deposition (CVD) tungsten carbide/tungsten coatings for application on mechanical seals that are used in heavy-duty rotating equipment for the chemical, oil and gas industries. Mechanical face seals are used in rotating equipment including turbines, compressors, and pumps to lubricate the mechanical assemblies, exclude abrasive media, and prevent leaks. Seal reliability is a key parameter for overall equipment reliability because seal failure can cause damage to expensive equipment, thus resulting in high downtime costs.

Hard Materials

Hard materials are widely utilized for heavy-duty mechanical face seals, especially in the making of highly durable ‘primary' sealing surface that can resist three-body abrasion, corrosion and erosion. Solid hard materials including sintered tungsten carbide, ceramic or silicon carbide are often utilized but they are expensive, brittle and difficult to produce, particularly if the seal design has finer features. There is a substantial difference between thermal expansion properties of solid hard materials and steel. This causes jamming when there is change in temperature.

Hard Coatings

A more efficient technique involves the application of hard coating on mechanical seal components made of steel, which is low cost, tough and much easier to machine. This method also paves the way for better seal design. There are different designs of mechanical seals available but normally these include the primary sealing surfaces, often created as two rings or disks, of which one is a stationary part and second is a rotating part. During the rotation of the seal at a rate of 1000 to 60,000 rpm and more, the mechanical face seal’s operation relies on the fluid layer isolating the primary seal components to lubricate their surfaces for friction reduction and overheating prevention. Coating these hard faces of a mechanical seal prevents scratching by hard particles and the creation of scratch asperities that may rupture the lubricating fluid film.

Hardide CVD Coatings

Hardide CVD tungsten carbide/tungsten coatings fulfill all the key prerequisites for mechanical seal applications. Although the optimal hardness for mechanical seal applications is between 1100 and 1800 Hv, Hardide produces its coatings with a hardness ranging between 450 and 3500 Hv. The typical thickness of Hardide coatings is 50 µm but the company produces thinner or thicker coatings of 5 to 100 µm for certain seal designs. It is possible to polish Hardide coatings to a good finish, typically reaching an Ra better than 0.3 µm by simply polishing without using expensive grinding. Hardide coatings’ uniform structure provides an even wear pattern that enables coated components to maintain an optimum finish for longer period even in the most abrasive environments. These coatings comprise tungsten carbide and tungsten, which resist chemically aggressive and corrosive media, especially acids. Their mechanical properties can be improved by alloying them with small quantities of fluorine or fluorocarbons.

Conclusion

With Hardide CVD hard coatings, users in high wear applications such as valves, pumps and down hole tools operating in power generation, cryogenic equipment, refineries, food manufacturing, and oil and gas facilities can reduce expenses by optimizing part life and improving product performance.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Carbide Tools and Chainsaw Technology to Make Hoof Trimming Easier

- Details

- Category: Tungsten Patents

- Published on Friday, 18 January 2013 11:16

- Hits: 2881

King Arthur’s Tools introduced Merlin® and Bors® to make hoof trimming a smoother and more economical experience. Merlin and Bors utilize chainsaw technology to present a breakthrough for the hoof trimming industry. The incorporation of a tungsten carbide chainsaw disc into both designs introduces a new technique for hoof trimmers to use. This allows the user to use arms and upper body strength to hold the blade at an angle to the hoof and peel layers away. The already existing labor-intensive chopping motion of current tools is subsequently eliminated. As a result, the new technique that Merlin and Bors utilize drastically reduces fatigue and strain on the wrist.

As new tools introduced into the hoof trimming industry, Merlin and Bors surpass barriers faced by current tools on the market. The inconvenience of sending blades away to be sharpened is eliminated by their new design. The manufacturer is effectively omitted from the blade sharpening process, as the user can effortlessly sharpen the blades of both Merlin and Bors onsite. These are the first tools in the industry that offer the user this high level of convenience.

The Merlin Hoof Trimming Set consists of a miniature long neck angle grinder and three specifically designed accessories for trimming, preparing and finishing hoofs. Bors carbide cutting blade fits standard 4 1/2" (115mm) angle or disc grinders and is designed for use in production on a high volume of hoofs.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Yes i4-TECH Putters

- Details

- Category: Tungsten Patents

- Published on Friday, 18 January 2013 13:51

- Hits: 2948

Golf is set to roll out a new line of putters under the “i4-TECH” banner in 2013.

Pictured here is the Yes i4-TECH Stephanie mallet putter, which may look sleek and slim on the outside, but is brimming with technology in the inside. It features a four-piece C-Groove insert (hence the i4-TECH label) with a polymer backing to “further enhance roll through increasing the friction between the ball and the groove edge…It has the added benefit of creating a softer feel.”

The Stephanie model also incorporates a tungsten weighting feature to elevate the MOI for added forgiveness, and has a curving black polymer strip along the crown with a contrasting white sightline for enhanced alignment.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten penetrators

- Details

- Category: Tungsten Patents

- Published on Friday, 18 January 2013 14:13

- Hits: 2941

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

A tungsten penetrator made by tungsten-nickel and other tungsten compounds

- Details

- Category: Tungsten Patents

- Published on Friday, 18 January 2013 14:38

- Hits: 2688

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Airbus to Trial Tungsten Carbide Coatings

- Details

- Category: Tungsten Patents

- Published on Friday, 18 January 2013 16:58

- Hits: 1854

Hardide Coatings Limited, which has developed a revolutionary tungsten carbide-based coating for chrome replacement programmes, has entered into a three year coatings approval test programme with Airbus and has confidence tests being performed at seven further key aerospace industry manufacturers.

The precision coating, which made its Farnborough debut in 2006, provides excellent wear resistance against abrasion, erosion and corrosion on components made from ferrous and nickel-based alloys. It coats internal surfaces and offers significant technical and environmental advantages over hard chrome and HVOF. Independent ASTM G65 testing has shown that Hardide wears out 40 times slower than abrasion resistant AR-500, 12 times slower than hard chrome and four times slower than thermal spray tungsten carbide.

The current primary market for the coating is the oil and gas exploration and production industry where Hardide-coated components are in widespread use in extreme downhole and drilling applications around the world. The coating is also in service in the valve, power, chemical and food manufacturing industries.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten metallization

- Details

- Category: Tungsten Patents

- Published on Tuesday, 22 January 2013 10:59

- Hits: 3263

This invention relates to metallization used in semiconductor devices.alternatives to aluminum have been sought for at least portions of the metallization. One commonly contemplated alternative metal is low pressure chemical vapor deposition (LPCVD) tungsten. LPCVD tungsten is a desirable alternative because it has a conformal step coverage. LPCVD tungsten also offers advantages for use as interconnects. Besides having conformal step coverage, it has high electromigration resistance, resistance to hillock formation and high temperature stability. Although many methods of depositing LPCVD tungsten have been proposed, they are all included within two generic categories which are conveniently termed selective and blanket.

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten alloy recovery

- Details

- Category: Tungsten Patents

- Published on Tuesday, 22 January 2013 11:10

- Hits: 3060

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com