Tungsten Slender Mud Recycling Strategy

- Details

- Category: Tungsten Information

- Published on Saturday, 02 June 2018 11:20

- Written by meiwei

- Hits: 417

In the process of beneficiation, the tungsten mine has a large amount of fine slime, which generally accounts for about 8%-10% of the ore. The recycled rate of the conventional tungsten slender mud process is generally low, about 20 - 30%. Therefore, the comprehensive recycle process and application of tungsten slender mud can be used to improve the comprehensive recycled rate of tungsten slender mud, reduce the waste of resources and reduce the cost of mineral processing. It is of great importance to increase the economic efficiency of enterprises.

Electrochromic Glass Coated Tungsten Nickel Alloy Target

- Details

- Category: Tungsten Information

- Published on Saturday, 02 June 2018 11:08

- Written by meiwei

- Hits: 514

The chromism and coating quality of tungsten nickel alloy target produced by the existing technology are still not stable enough, resulting in low yield and high cost of electrochromic glass, more wastes such as waste acid and other pollutants are produced.

Read more: Electrochromic Glass Coated Tungsten Nickel Alloy Target

Tungsten Mineral Raw Materials Decomposition by Far Infrared Hot Pressing

- Details

- Category: Tungsten Information

- Published on Saturday, 02 June 2018 10:35

- Written by meiwei

- Hits: 408

In order to optimize the technological process, energy saving and emission reduction, the researchers put forward a far infrared hot press decomposition of tungsten mineral raw materials to achieve a clean production process for the full decomposition of tungsten minerals in wet tungsten smelting. The characteristics of the process are as follows:

Read more: Tungsten Mineral Raw Materials Decomposition by Far Infrared Hot Pressing

Tungsten and Molybdenum Separation by Quaternary Ammonium Salt Extraction

- Details

- Category: Tungsten Information

- Published on Saturday, 02 June 2018 10:55

- Written by meiwei

- Hits: 513

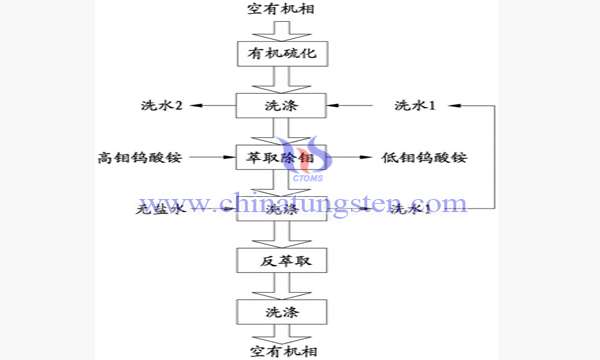

Separation of tungsten and molybdenum has been the focus of tungsten and molybdenum smelting technology research and development. Some researchers have proposed a method of extraction and separation of tungsten and molybdenum by extraction and separation of ammonium tungstate solution by N263- paraoctanol - kerosene system, which consists of 20% N263, 20% isooctanol and 60% kerosene, O/A=1:1.

Read more: Tungsten and Molybdenum Separation by Quaternary Ammonium Salt Extraction

A New Type of Tungsten Concentrates Dryer

- Details

- Category: Tungsten Information

- Published on Saturday, 02 June 2018 10:20

- Written by meiwei

- Hits: 397

The traditional tungsten concentrates bake converter is heating through the drying oven. The main fuel of the oven is coal or dry wood. This drying method shows the following shortcomings in the production practice: first, it causes environmental pollution and consumes a lot of wood; Second, it is that both coal and dry wood need a larger fuel yard, and the effect is affected.

sales@chinatungsten.com

sales@chinatungsten.com