Superfine Tungsten Powder to Boost Super Coarse Grained Cemented Carbide

- Details

- Category: Tungsten Information

- Published on Monday, 30 July 2018 10:05

- Written by meiwei

- Hits: 474

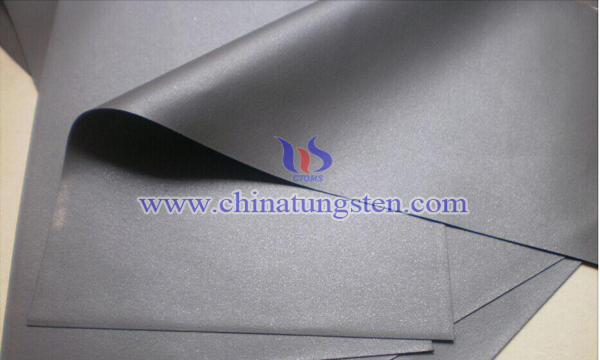

supercoarse grain cemented carbide image

The main method of producing super coarse grained cemented carbide is the use of super coarse tungsten carbide powder and cobalt powder as raw materials. It is pressed and sintered to become a product after batching, ball milling, drying and granulation. However, the ultra coarse tungsten carbide powder will break in the process of ball milling, and the grain size will decrease greatly. During the sintering process, the WC grain can not grow into an ultra coarse grained WC grain.

Read more: Superfine Tungsten Powder to Boost Super Coarse Grained Cemented Carbide

Tungsten-Molybdenum Alloy Rotating Target

- Details

- Category: Tungsten Information

- Published on Sunday, 29 July 2018 23:36

- Written by meiwei

- Hits: 523

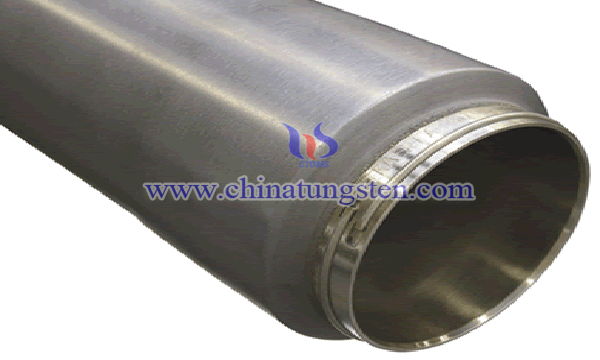

tungsten-molybdenum alloy rotating target image

TFT film has the advantages of high responsivity, high brightness and high contrast. It is one of the basic materials in many industries. Therefore, it is widely used in the fields of solar cells, liquid crystal displays and plasma displays. In recent years, along with the rapid development of high-end displays, tungsten molybdenum alloy rotating target is an important material for preparing TFT film.

Arsenic Assisted Tungsten Carbide Powder Refinement

- Details

- Category: Tungsten Information

- Published on Sunday, 29 July 2018 23:15

- Written by meiwei

- Hits: 565

tungsten carbide powder image

arsenicTungsten carbide powder is the main raw material for the preparation of cemented carbide. At present, the preparation of ultra-fine tungsten carbide powder mainly includes conventional tungsten oxide hydrogen reduction-carbonization method, tungsten oxide direct reduction carbonization method, plasma chemical synthesis method, mechanical alloying method. The quality of tungsten powder directly affects the performance of cemented carbide products. In order to obtain high-performance ultra-fine WC-Co cemented carbide, the grain size of tungsten carbide must be controlled. Therefore, the preparation of ultrafine tungsten carbide powder with good dispersibility and uniform particle size distribution is the key technology for the preparation of ultrafine grained WC-Co cemented carbide.

Read more: Arsenic Assisted Tungsten Carbide Powder Refinement

Preparation of Tungsten Oxide Nanowires by Hydrothermal Synthesis

- Details

- Category: Tungsten Information

- Published on Sunday, 29 July 2018 23:29

- Written by meiwei

- Hits: 449

preparation of tungsten oxide nanowires by hydrothermal synthesis image

In the existing technology, the synthesis of tungsten oxide nanowires is mainly included in the following methods: high temperature vacuum vapor deposition, surfactant method, or anodic alumina template method. Compared with the above methods, the hydrothermal preparIn the existing technology, the synthesis of tungsten oxide nanowires is mainly included in the following methods: high temperature vacuum vapor deposition, surfactant method, or anodic alumina template method. Compared with the above methods, the hydrothermal preparation process is very simple and most widely used.ation process is very simple and most widely used.

Read more: Preparation of Tungsten Oxide Nanowires by Hydrothermal Synthesis

Tungsten Recycling from Low Grade Scheelite Tailings

- Details

- Category: Tungsten Information

- Published on Sunday, 29 July 2018 22:59

- Written by meiwei

- Hits: 562

tungsten recycle from low grade scheel tailings image

At present, the content of WO3 in white tungsten flotation tailings in many mines has reached more than 0.2%, even as high as 0.4%. These tailings are very low in floatability due to strong inhibition of inhibitor water glass, and the size of the inlay is very fine. It is very difficult and difficult to recycle.

Read more: Tungsten Recycling from Low Grade Scheelite Tailings

sales@chinatungsten.com

sales@chinatungsten.com