Low Cost Treatment of Tungsten Waste

- Details

- Category: Tungsten Information

- Published on Saturday, 04 August 2018 22:47

- Written by meiwei

- Hits: 462

low cost treatment of tungsten waste image

Tungsten containing waste is complex, difficult to extract and complicated. This kind of APT is manufactured by traditional methods with long process flow, narrow range of raw materials, large investment in equipment, unstable products and poor economic benefits. In recent years, people have made some explorations in the preparation of ammonium parotungstate from waste materials containing tungsten and achieved some results.

Reclaiming Rubidium from Rubidium Tungsten Ore

- Details

- Category: Tungsten Information

- Published on Saturday, 04 August 2018 22:34

- Written by meiwei

- Hits: 824

rubidium tungsten ore image

Rubidium (Rb) is a dilute chemical substance, very soft silver white wax metal. It is soft and light, and its chemical properties are more active than potassium. It can be used for the production of special glass, micro high energy battery and crystal scintillation counter. The minerals containing rubidium are mica and potash feldspar, mainly in wolframite and scheelite.

Invalidation Mode of Tungsten Carbide Mining Button

- Details

- Category: Tungsten Information

- Published on Friday, 03 August 2018 18:26

- Written by yating

- Hits: 517

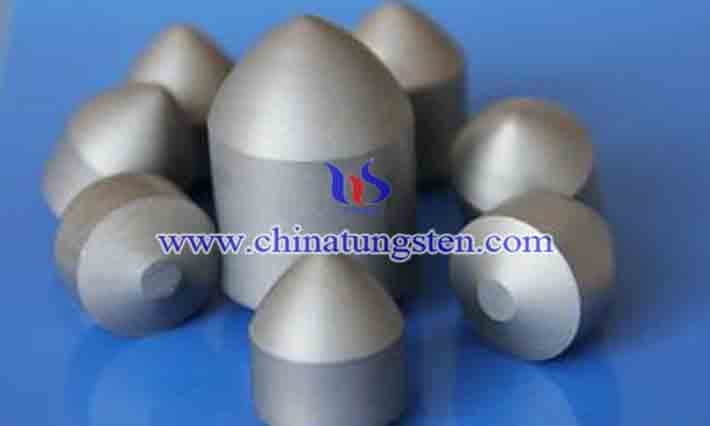

tungsten-carbide-mining-button-picture

The tungsten carbide mining button is composed of mining button handle, button head and alloy cutter head. The mining button handle and its cutter head are collectively referred to knife body. Its hardness is 40-45HRC. The pounding tenacity is not less than 49J/cm2.

Read more: Invalidation Mode of Tungsten Carbide Mining Button

Production Method of Near-Spherical Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Friday, 03 August 2018 19:15

- Written by yuntao

- Hits: 611

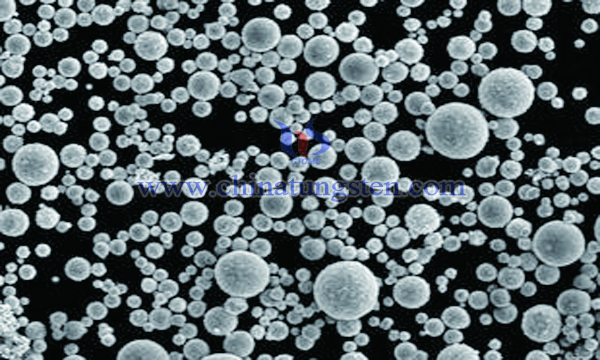

near spherical tungsten powder picture

The tungsten powder commonly used in the industry is mainly obtained by reducing tungsten oxide with hydrogen. Such tungsten powder has irregular particle shape, poor fluidity, low bulk density, and it is difficult to obtain a tungsten body with continuous micropores by sintering. In recent years, the demand for near-spherical or spherical tungsten powder has increased day by day, and is widely used in powder metallurgy processes such as porous material preparation, thermal spraying and injection molding.

Read more: Production Method of Near-Spherical Tungsten Powder

Tungsten-Lanthanum Alloy Wire

- Details

- Category: Tungsten Information

- Published on Friday, 03 August 2018 18:23

- Written by yuntao

- Hits: 493

tungsten wire picture

The current tungsten filaments in bulbs are tungsten alloy wires made of ammonium paratungstate (APT) as main material with potassium, aluminum and silicon. This tungsten alloy wire thus has the disadvantages of low cold resistance, low thermal resistance, and poor photoelectric performance. In the process of tungsten wire manufacture, the rotary forging and drawing process will harden the tungsten alloy, and increases internal stress, thus it is easy to break when pulling; this increases the difficulty of production. The hardening of the alloy and the presence of internal stresses result in a shorter service life of the tungsten wire and poorer impact resistance, and the filament is prone to sagging after use.

sales@chinatungsten.com

sales@chinatungsten.com