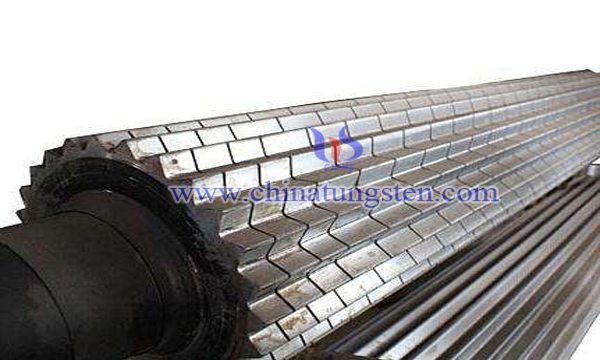

Corrugated Roll Tungsten Carbide Cobalt Coating Reinforcement

- Details

- Category: Tungsten Information

- Published on Tuesday, 25 September 2018 23:51

- Written by meiwei

- Hits: 592

Thermal spraying technology is a key technology in the field of surface modification. As a wear-resistant and corrosion-resistant coating, tungsten carbide/cobalt coating is widely used in aerospace, metallurgy, machinery and other fields because of its high hardness and good toughness. Compared with hard chromium plating, thermal sprayed WC-Co coating has obvious advantages in wear resistance, corrosion resistance, fatigue resistance and so on, and has the advantages of rapid preparation and less environmental pollution.

Read more: Corrugated Roll Tungsten Carbide Cobalt Coating Reinforcement

Tungsten Oxide Electrochromic Film

- Details

- Category: Tungsten Information

- Published on Tuesday, 25 September 2018 17:49

- Written by anyang

- Hits: 526

A variety of color-changing films can be seen everywhere in life, and the materials for making color-changing films are very wide. One of the new materials is the tungsten oxide electrochromic film.

Advantages of Nano Tungsten Oxide Insulating Glass

- Details

- Category: Tungsten Information

- Published on Tuesday, 25 September 2018 14:37

- Written by anyang

- Hits: 602

Nano tungsten oxide heat-insulating glass is one kind of coated glass, which is produced through mixing a mixture of 5-10nm nano tungsten oxide and indium-phosphide oxide with resin and diluent, and then coat on the glass surface. The new coated glass has the advantages of good heat insulation performance, high transparency and good anti-UV effect, and is widely used in architectural glass curtain wall, vehicle and ship glass and other industries.

Read more: Advantages of Nano Tungsten Oxide Insulating Glass

Researchers Have Developed A New Tungsten Oxide Nanofiber Membrane

- Details

- Category: Tungsten Information

- Published on Tuesday, 25 September 2018 16:08

- Written by anyang

- Hits: 589

The life on earth is inseparable from the sun. With the development of science and technology, people realize that sunlight provides enough renewable green energy to achieve higher solar-thermal energy conversion efficiency and achieve more efficient water evaporation performance. The topic of photothermal materials----tungsten oxide nanofiber membranes is constantly being explored.

Read more: Researchers Have Developed A New Tungsten Oxide Nanofiber Membrane

Tungsten Oxide Insulating Glass Could Protect Children's Skin Health

- Details

- Category: Tungsten Information

- Published on Friday, 21 September 2018 20:52

- Written by anyang

- Hits: 591

Tungsten oxide insulating glass can effectively prevent ultraviolet rays come into the room, and protect people skin health, especially for infants’ and children’ skin health.

Read more: Tungsten Oxide Insulating Glass Could Protect Children's Skin Health

sales@chinatungsten.com

sales@chinatungsten.com