Breaking The Semiconductor 3nm Process Limit, Scientists Successfully Developed 0.7nm Tungsten Selenide Diode

- Details

- Category: Tungsten Information

- Published on Wednesday, 16 January 2019 09:18

- Written by tang

- Hits: 594

WSe2 picture

It is reported that a few days ago, scientists successfully developed a 0.7nm tungsten selenide diode, which means that humans have finally broken the semiconductor 3nm process limit, and toward the development of semiconductor technology, and took a small step forward! Why do you say that? As you may be keen on semiconductors, semiconductor process technology is rapidly evolving with the development of smartphones from 28nm, 16nm, 10nm, 7nm, 5nm to 3nm. However, in this process, the miniaturization process of the semiconductor process is also slowing down due to the gradual failure of Moore's Law.

Tungsten Copper Alloy Will Replace Copper Into Mainstream Armored Ammunition Drug Cover Material

- Details

- Category: Tungsten Information

- Published on Tuesday, 15 January 2019 09:24

- Written by tang

- Hits: 625

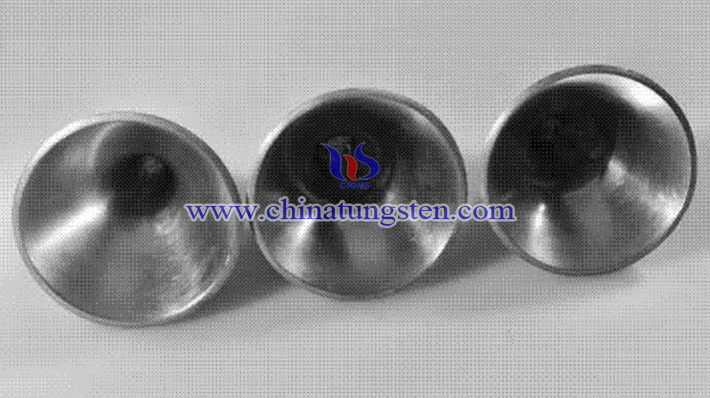

armor penetration effect of tungsten copper alloy liner picture

Can the tungsten copper alloy cover replace the copper type cover as the mainstream? After consulting the relevant literature, it is found that long and stable metal jet is essential to achieve the desired armor effect, and the medicinal mask material is the key to the formation of high-speed jets. Ground is the key to controlling the shape, size and quality of metal jets. Furthermore, according to the theory of penetrating fluid dynamics, the penetration depth of the metal jet is proportional to the square root of the jet length and material density. That is to say, the medicinal mask should form a longer and more stable metal jet, and the medicinal mask material should have the characteristics of high density, high sound speed and good shape.

Sun Room Warm Insulation Artifact, Cesium Tungsten Bronze Nano Transparent Insulation Coating

- Details

- Category: Tungsten Information

- Published on Friday, 11 January 2019 09:37

- Written by tang

- Hits: 690

cesium tungsten picture

Tungsten - the most refractory metal with the highest melting point. Tungsten is also an important strategic metal and is widely used in the military for its high density, high strength, high toughness, impact resistance, good shape, armor penetration and non-toxic environmental protection. Among them, tungsten alloys are used to manufacture various high-speed ammunition, especially armor-piercing projectiles, which can compete directly with depleted uranium bombs because of their extremely stable dynamic plastic deformation properties. As you may know, depleted uranium has become an environmental issue! Tungsten can also be used to protect or protect the outer casing of nuclear weapons materials. China's tungsten reserves are the world's number one!

The Armor-Piercing Ammunition Cover Material Is Not Only Copper, Nickel And Tantalum, But Also Tungsten And Molybdenum

- Details

- Category: Tungsten Information

- Published on Monday, 14 January 2019 10:14

- Written by tang

- Hits: 790

tungsten alloy liner picture

HEAT is the abbreviation of the English "High-Explosive Anti-Tank" of the armor-piercing projectile. At the same time, most of them know that the armor-piercing projectile has another name: the hollow charge armor-piercing projectile or the gather-charged armor-piercing projectile. The chemical energy anti-armored ammunition developed based on the Monroe effect (concentration effect) is mainly used to damage armored targets such as tanks and armored vehicles. It is commonly found in tank guns, anti-tank guns, and anti-tank missiles. The hood is the "heart" of HEAT! However, in fact, the armor-type ammunition cover material is not only copper, nickel, and antimony.

Tungstate Oxidative Desulfurization Catalytic Practice

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 January 2019 22:49

- Written by meiwei

- Hits: 472

tungstate oxidative desulfurization catalytic practice image

With the rapid development of automotive industry, sulfur pollution caused by combustion of automotive fuels is becoming more and more serious. Strict sulfur content standards for gasoline and diesel have been formulated in various countries and regions of the world. Hydrodesulfurization (HDS) is usually used in industry to remove sulfides from gasoline and diesel oil, but for thiophene and its derivatives, due to the steric hindrance effect, the desulfurization effect is poor and the cost is high.

Read more: Tungstate Oxidative Desulfurization Catalytic Practice

sales@chinatungsten.com

sales@chinatungsten.com