Two-dimensional Tungsten Oxide Nanosheet Preparation Method

- Details

- Category: Tungsten Information

- Published on Thursday, 31 January 2019 23:10

- Written by meiwei

- Hits: 450

Tungsten oxide is an important transition metal oxide semiconductor with excellent electrochromic, photochromic and field emission properties. It has important application prospects in the fields of solar energy utilization, intelligent display, visible light photocatalysis, chemical sensing and so on.

Read more: Two-dimensional Tungsten Oxide Nanosheet Preparation Method

Carbon-coated Potassium Phosphotungstate Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 28 January 2019 22:20

- Written by meiwei

- Hits: 437

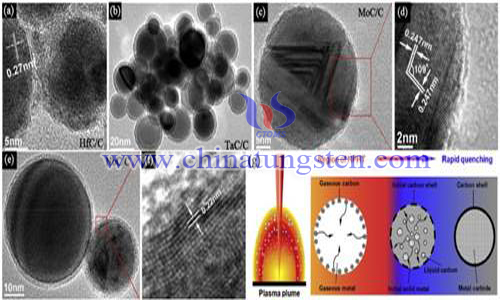

Potassium phosphotungstate (K3PW12O40) is a kind of Heteropoly acid. Potassium phosphotungstate, as a cathode active material in the molecular cluster of Heteropoly acid, has attracted much attention due to its reversible multi-electron redox reaction, which enables it to achieve a high specific capacity of 260 Ah/kg (ordinary Li2CoO2 lithium ion battery is 150 Ah/kg) and fast charge-discharge performance.

Read more: Carbon-coated Potassium Phosphotungstate Preparation

Bismuth Tungstate Photocatalyst Preparation by Sol-gel Method

- Details

- Category: Tungsten Information

- Published on Sunday, 27 January 2019 23:13

- Written by meiwei

- Hits: 493

Photocatalysis can effectively convert light energy into chemical energy. Bi2WO6, as a new visible light-responsive photocatalytic material, has a narrow band gap (2.7eV), good photocatalytic activity under ultraviolet and visible light, and can effectively degrade organic pollutants in wastewater.

Read more: Bismuth Tungstate Photocatalyst Preparation by Sol-gel Method

Low Energy Consumption Tungstate Extraction Method

- Details

- Category: Tungsten Information

- Published on Monday, 28 January 2019 22:06

- Written by meiwei

- Hits: 452

With the development of modern science and technology, higher requirements are put forward for the preparation of tungsten, tungsten alloys and tungsten compounds. Tungstate is an important intermediate material in tungsten smelting, and its preparation and technological research have important value and significance.

Read more: Low Energy Consumption Tungstate Extraction Method

Tungsten Carbide High Wear Resistance Composite Steel Plate Preparation by Hot Furnace Method

- Details

- Category: Tungsten Information

- Published on Sunday, 27 January 2019 20:26

- Written by meiwei

- Hits: 474

In the field of industrial production, metal wear is one of the main causes of failure of mechanical parts, such as material conveying systems in metallurgy, coal, power, waterway dredging and other industries, parts wear very seriously. Wear not only causes great loss of materials, but also causes the shutdown of production and affects the normal operation of production line. Therefore, the research and development of high wear resistant materials has been paid attention by material workers.

sales@chinatungsten.com

sales@chinatungsten.com