How to Prepare Porous Silicon / Multidimensional Tungsten Oxide Composites

- Details

- Category: Tungsten Information

- Published on Saturday, 02 February 2019 22:57

- Written by meiwei

- Hits: 522

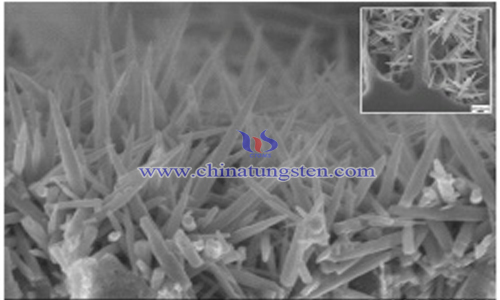

Tungsten oxide, as a semiconductor sensitive material with great research and application prospects, has been widely used to detect various toxic and dangerous gases (such as NO2, NH3, etc.). However, the working temperature of tungsten oxide is relatively high (150 ~250 ℃), so scientists and technicians have been devoting themselves to the research of reducing the working temperature of tungsten oxide.

Read more: How to Prepare Porous Silicon / Multidimensional Tungsten Oxide Composites

Supported Bismuth Tungstate Photocatalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 02 February 2019 22:43

- Written by meiwei

- Hits: 513

Bismuth tungstate (Bi2WO6) photocatalyst is considered as a potential excellent visible light photocatalytic material because of its unique electronic structure, excellent visible light absorption ability and high organic degradation ability.

Tungsten Carbide / Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Friday, 01 February 2019 21:37

- Written by meiwei

- Hits: 579

With the rapid development of global economy and the increasing demand for energy and resources, people pay more attention to and invest in the search for renewable and clean energy. Hydrogen energy, as a clean renewable energy, has the advantages of high combustion value, pollution-free, convenient storage and transportation. The photocatalytic decomposition of water to produce hydrogen using solar energy, which has huge reserves and no pollution, provides an ideal method to solve this problem, and has become a hot spot of scientific research.

Nano Silver / Tungsten Trioxide Photocatalyst

- Details

- Category: Tungsten Information

- Published on Friday, 01 February 2019 21:52

- Written by meiwei

- Hits: 561

Tungsten trioxide (WO3) is an important photocatalytic semiconductor material, which is widely used in the field of semiconductor heterogeneous photocatalytic technology to solve industrial wastewater and domestic wastewater pollution treatment.

Nano Tungsten Carbide Perfect Carbonization

- Details

- Category: Tungsten Information

- Published on Friday, 01 February 2019 21:27

- Written by meiwei

- Hits: 477

Nano-cemented carbide not only has high hardness, good wear resistance, but also has high strength and toughness, and has good comprehensive properties. Its application field is expanding constantly. It has been widely used in manufacturing micro-drills, precision tooling and difficult cutting fields. As the basic raw material of nano-cemented carbide production, nano tungsten carbide has been prepared and its properties for the production of nano-cemented carbide. It has a great influence and has almost become the bottleneck in the production of nano-cemented carbide. For this reason, many enterprises and research institutes in many countries have carried out a lot of research.

sales@chinatungsten.com

sales@chinatungsten.com