Tungsten Target Back Plate Welding

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 February 2019 21:57

- Written by meiwei

- Hits: 1825

In the semiconductor industry, the target assembly is composed of a target which meets the sputtering performance and a backplane which can be combined with the target and has a certain strength. The backplane can play a supporting role in assembling the target assembly to the sputtering base, and has the effect of conducting heat. For example, tungsten metal can be selected as target material, copper or copper alloy material with sufficient strength and high thermal conductivity can be selected as backplane to form target component.

Vacuum Extension Method for Tungsten Target Preparation

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 February 2019 21:49

- Written by meiwei

- Hits: 499

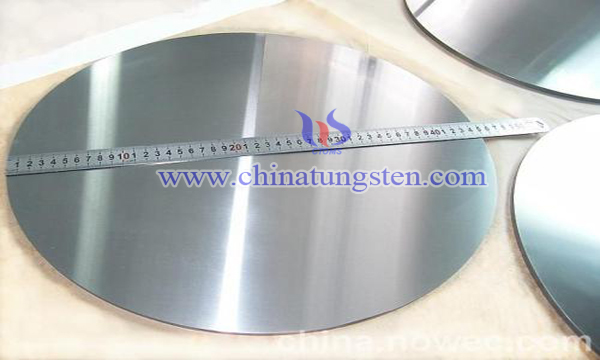

Large-scale integrated circuits often use tungsten target for vacuum sputtering, especially large-size tungsten target. In the current semiconductor field, large-size tungsten target has a diameter of 300 mm-450 mm and a thickness of 6 mm-15 mm. However, with the development of semiconductor industry, tungsten target of this size can not meet the industrial needs.

Read more: Vacuum Extension Method for Tungsten Target Preparation

Exploration on Preparation Process of Large Size Tungsten Target

- Details

- Category: Tungsten Information

- Published on Saturday, 09 February 2019 23:23

- Written by meiwei

- Hits: 681

Sputtering is one of the main technologies for preparing thin film materials. Atomics emitted by high-speed moving ions bombarding the target accumulate on the surface of the substrate to form a coating. The bombarded solid is the raw material for deposition of thin film by sputtering, which is called sputtering target.

Read more: Exploration on Preparation Process of Large Size Tungsten Target

Tungsten Oxide Electrochromic Glass, Easy To Achieve Warm Winter And Cool Summer

- Details

- Category: Tungsten Information

- Published on Monday, 11 February 2019 09:28

- Written by tang

- Hits: 659

According to experts, in the near future, tungsten oxide electrochromic glass can easily achieve warm winter and cool summer! It is said that this is a black technology achievement! Just press the power switch lightly to make the glass "discolor" instantly, from transparent to dark blue. Ordinary glass does not have thermal insulation, and this black technology can make the glass block most of the sunlight in the hot summer, reduce the indoor temperature, thus reducing air conditioning costs and saving energy. Some experts also said that this kind of glass has a certain thermal insulation effect. Moreover, unlike other materials, it only consumes power during the state transition.

Read more: Tungsten Oxide Electrochromic Glass, Easy To Achieve Warm Winter And Cool Summer

Comprehensive Recovery Strategy of Tungsten Molybdenum Bismuth Fluorite Polymetallic Ore

- Details

- Category: Tungsten Information

- Published on Saturday, 09 February 2019 23:14

- Written by meiwei

- Hits: 505

Shizhuyuan Tungsten-Molybdenum-Bismuth Polymetallic Ore in Hunan Province, China belongs to a large SKARN-TYPE polymetallic ore body. There are many valuable minerals in the ore with complex distribution relationship and low grade. It is difficult to separate more than 20 kinds of ore, such as tungsten, molybdenum, bismuth, iron and fluorite. How to effectively separate and comprehensively recover valuable minerals has become a hot academic topic for scholars at home and abroad.

Read more: Comprehensive Recovery Strategy of Tungsten Molybdenum Bismuth Fluorite Polymetallic Ore

sales@chinatungsten.com

sales@chinatungsten.com