Tungsten Carbide-Titanium Carbide Solid Solution New Preparation Process

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 21:51

- Written by meiwei

- Hits: 1078

The traditional method of preparing tungsten carbide-titanium carbide solid solution is to use industrial titanium dioxide and WC as raw materials, carbon black as reducing agent, mix with ball mill, and react in graphite tube electric furnace at the temperature of 2000-2300 ℃. The preparation method has the following shortcomings: first, the ball mill has low ball milling efficiency, mainly mixing effect on raw materials and little crushing effect. Second, the high reaction temperature makes the sintering growth of the prepared tungsten carbide-titanium carbide solid solution obvious.

Read more: Tungsten Carbide-Titanium Carbide Solid Solution New Preparation Process

SCR Catalyst Recovery Process Improvement

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 21:15

- Written by meiwei

- Hits: 1199

SCR denitrification technology has the advantages of high denitrification efficiency, over 90%, good selectivity and reliable technology. Catalyst is the core of SCR denitrification technology. At present, the commonly used SCR denitrification catalyst is based on titanium dioxide as carrier, V2O5 as active component, WO3 or MoO3 as structural promoter. The activity of catalyst directly determines the efficiency of denitrification.

Silver Tungstate Photocatalyst Preparation

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 20:28

- Written by meiwei

- Hits: 1110

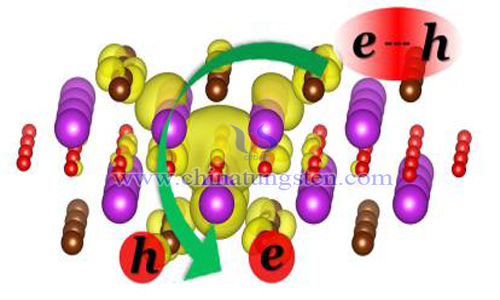

Tungsten oxide is a semiconductor photocatalyst with visible light response. Tungsten oxide particles can absorb most of the visible light occupying the room space. However, because the conduction band is located at the energy level of oxygen-specific oxidation-reduction, oxygen can not be reduced in the electrons stimulated by the conduction band, and the amount of reactive oxygen species is insufficient. Therefore, tungsten oxide can not show high photocatalytic activity in the environment of visible light irradiation but not ultraviolet light irradiation.

Titanium Tungsten Alloy by Molten Salt Electrolysis

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 20:54

- Written by meiwei

- Hits: 2971

At present, the main methods for preparing Ti-W alloys are high temperature vacuum melting, powder metallurgy and mechanical alloying. However, these methods have some disadvantages, such as high production cost, complex process or low purity of products, which reduce the properties of Ti-W alloys and greatly limit their application.

Read more: Titanium Tungsten Alloy by Molten Salt Electrolysis

How to Extract Cobalt and Tungsten from Waste Cemented Carbide

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 20:21

- Written by meiwei

- Hits: 1074

With the rapid development of economy, the demand for tungsten and cobalt in machinery manufacturing, geology, mining, construction, electronics and chemical industries is increasing. As rare metal elements, tungsten and cobalt are also the main raw materials of cemented carbide. Therefore, it is very meaningful to recycle tungsten and cobalt from scrap cemented carbide.

Read more: How to Extract Cobalt and Tungsten from Waste Cemented Carbide

sales@chinatungsten.com

sales@chinatungsten.com