Preparation of Acrolein by Phosphotungstic Acid Modified Catalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 July 2019 13:34

- Written by yuntao

- Hits: 1112

Acrolein is an important fine chemical intermediate with a wide range of applications in coatings, paper, oil, medicine, and organic synthesis industries. In recent years, with the increasing demand of animal feed additives such as methionine, glutaraldehyde, pesticides and water treatment agents on the market, and the large excess of bio-glycerol, the rapid development of the acrolein industry has been promoted.

Read more: Preparation of Acrolein by Phosphotungstic Acid Modified Catalyst

Cobalt-Tungsten Carbide Alloy Thermal Spray Coating Applied in Aero Engines

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 July 2019 01:12

- Written by yuntao

- Hits: 1145

Cobalt-tungsten carbide alloy thermal spray coating is the highest hardness wear resistant coating below 540 °C. Due to its combination of good hardness and toughness, it is widely used in aviation, aerospace, automotive, transportation, metallurgy, electric power, etc. Strengthen the wear resistance of the base metal and repair the worn fatigue parts.

Read more: Cobalt-Tungsten Carbide Alloy Thermal Spray Coating Applied in Aero Engines

Adipic Acid Synthesis with Nano Tungsten Trioxide Catalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 23:10

- Written by meiwei

- Hits: 1161

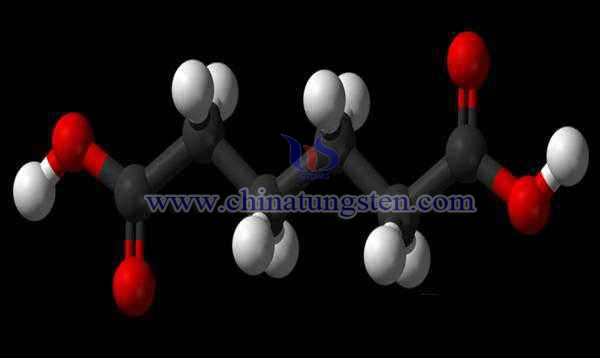

Adipic acid is an important organic dibasic acid, which is mainly used in synthetic fibers, namely nylon-66. The annual consumption of adipic acid is very large. At present, the traditional production process of adipic acid synthesis is still widely used in industry, that is, using concentrated HNO3 as oxidant. This process is very harmful to the environment.

Read more: Adipic Acid Synthesis with Nano Tungsten Trioxide Catalyst

Silver-Tungsten Carbide-Carbon Electric Contact

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 23:20

- Written by meiwei

- Hits: 1149

In recent years, with the development of low-voltage electrical industry, various series of new circuit breakers have been introduced. These new circuit breakers require contact materials with smaller volume and higher breaking capacity. At present, the matching of AgWC12C3 and AgW50 is often used as asymmetrical and reasonable matching contacts of circuit breakers in AgWC-C electrical contact materials, so as to improve the arc resistance and material transfer resistance of AgWC-graphite electrical contact materials, which is the necessary condition for expanding the application range of AgWC-graphite contact materials and meeting the increasingly stringent performance requirements of circuit breakers for contact materials.

Cesium Tungsten Bronze Ultrafine Powder Preparation

- Details

- Category: Tungsten Information

- Published on Saturday, 29 June 2019 23:02

- Written by meiwei

- Hits: 1193

Tungsten trioxide is recognized as an excellent electrochromic material. It has excellent properties in electrochromic, catalytic and gas sensitivity. Tungsten bronze, a composite oxide of tungsten bronze, generally refers to metal oxides with deep metallic luster, and is usually metal conductors or metal semiconductors.

Read more: Cesium Tungsten Bronze Ultrafine Powder Preparation

sales@chinatungsten.com

sales@chinatungsten.com