A Tungsten Lubricating Oil Additive

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 11:12

- Written by meiwei

- Hits: 1146

Diesel engine oil is mainly composed of paraffin base oil or synthetic lubricant, which is prepared by adding many additives such as antioxidant, antiseptic, detergent and dispersant, antifriction agent and so on.

Tungsten Molybdenum Alloy Sputtering Targets

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 11:07

- Written by meiwei

- Hits: 1152

Tungsten molybdenum alloys can be used at higher temperatures than molybdenum or molybdenum alloys. Molybdenum-tungsten alloy has better conductivity, oxidation resistance and lower coating stress than molybdenum, which meets the requirement of sputtering target material for flat display film production line. Especially the Mo-W alloy with tungsten content of 3.5%25% is more suitable for high quality flat panel display.

Tungsten Aluminum Alloy Preparation by High Current Pulsed Electron Beam

- Details

- Category: Tungsten Information

- Published on Thursday, 04 July 2019 21:56

- Written by meiwei

- Hits: 1142

Tungsten aluminum alloys have excellent properties of both aluminium and tungsten, such as low density, high specific strength, high temperature resistance, corrosion resistance and easy processing. In addition to the advantages of aluminium and tungsten, aluminium-tungsten alloy also has the greatest feature of wear resistance, which can be well applied to golf clubs and ball heads, medical equipment components (breathing machines), automotive engine piston, hub and other components, and hopefully in the future to be applied to armor materials and aerospace engines and other fields.

Read more: Tungsten Aluminum Alloy Preparation by High Current Pulsed Electron Beam

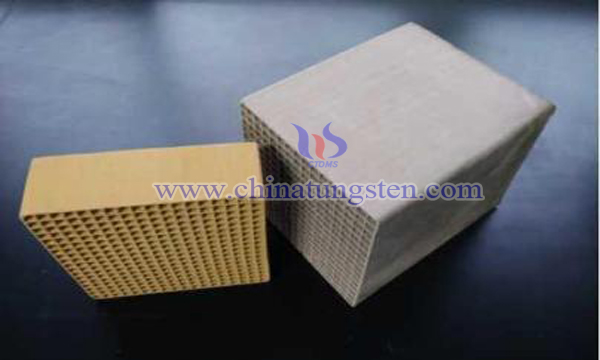

Cerium Tungsten Tantalum Catalyst for Denitrification

- Details

- Category: Tungsten Information

- Published on Saturday, 06 July 2019 11:03

- Written by meiwei

- Hits: 1140

In recent years, selective catalytic reduction (SCR) has been widely used as the most efficient denitrification technology at present. The principle of this air pollution control technology is that in the presence of reducing agent NH3, the flue gas containing NOx reacts with the surface of the catalyst in a certain temperature range through the catalyst, making NOx react with the surface of the catalyst. The NH3 reaction is converted into harmless N2 and H2.

Read more: Cerium Tungsten Tantalum Catalyst for Denitrification

Ammonium Metatungstate Improvement Process

- Details

- Category: Tungsten Information

- Published on Thursday, 04 July 2019 21:51

- Written by meiwei

- Hits: 1177

Ammonium metatungstate powder is widely used in chemical industry as raw material of petroleum cracking catalyst, corrosion inhibitor (anticorrosive coating or coating) for electronic components, and as important raw material for preparing composite powder, doped tungsten wire and tungsten-cerium electrode in the production of tungsten products.

sales@chinatungsten.com

sales@chinatungsten.com