Metallization of Alumina Single Crystal Tungsten Yttrium

- Details

- Category: Tungsten Information

- Published on Saturday, 03 August 2019 23:38

- Written by meiwei

- Hits: 1413

Metallization modification of the welded surface of alumina composite single crystal is the precondition of reliable sealing with metal. Conventional molybdenum-manganese metallization process, sintering temperature is generally about 1400 ℃, later welding or use process exceed this temperature, the glass phase in the metallized layer will flow, destroy the metallized layer, thereby affecting the sealing strength and sealing gas tightness of ceramics-metal and other properties. Moreover, the low metallization sintering temperature also limits the selection of high temperature quinone solder for sealing alumina composite single crystal with metal, and directly limits the high temperature use of sealing parts.

Read more: Metallization of Alumina Single Crystal Tungsten Yttrium

Tungsten Salt Lubricant Oil Additives Containing Carboxylic Acid

- Details

- Category: Tungsten Information

- Published on Saturday, 03 August 2019 23:18

- Written by meiwei

- Hits: 1466

Vehicles in high temperature and high speed must be fully lubricated between moving parts to ensure normal operation. Lubrication system plays an important role in lubrication, cleaning, cooling and rust prevention of engine friction surfaces.

Read more: Tungsten Salt Lubricant Oil Additives Containing Carboxylic Acid

Dental Tungsten Carbide Grinding Needle

- Details

- Category: Tungsten Information

- Published on Saturday, 03 August 2019 22:28

- Written by meiwei

- Hits: 1354

In the field of powder metallurgy manufacturing technology, grinding needles made of powder cemented carbide are widely used in mechanical drilling and dressing of jades, mechanical drilling of printed circuit boards, etc. Tungsten carbide grinding needle is a kind of cemented carbide grinding needle. Its structure is characterized by solid grinding needle, small diameter, long length, small tolerance range of length and size and high requirement of verticality.

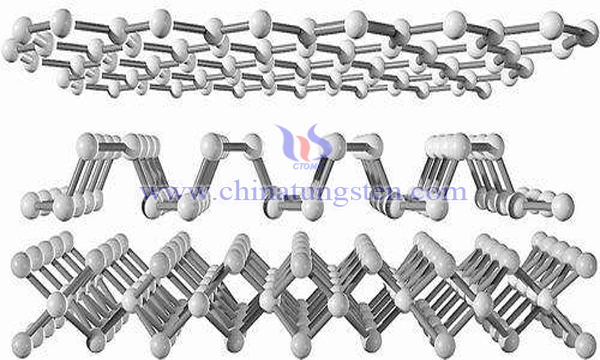

Tungsten Oxide Nanometer Gas Sensing Materials Preparation with Multiple Surface Defects

- Details

- Category: Tungsten Information

- Published on Saturday, 03 August 2019 22:58

- Written by meiwei

- Hits: 1226

In the field of semiconductor gas sensitive materials, tungsten oxide (WO3) has become the research focus of nano gas sensitive materials in recent years because of its easy regulation, strong selectivity, good stability, high sensitivity and low gas sensitive working temperature.

Read more: Tungsten Oxide Nanometer Gas Sensing Materials Preparation with Multiple Surface Defects

Staged Synthesis of High-purity Nano Bismuth Tungstate

- Details

- Category: Tungsten Information

- Published on Friday, 02 August 2019 13:30

- Written by yuntao

- Hits: 1320

Photocatalytic reactions can degrade almost all organic contaminants such as alkanes, halogenated alkanes, alcohols, carboxylic acids, alkenes, aromatic hydrocarbons, halogenated aromatic compounds, polymers, insecticides, herbicides, dyes and brominated flame retardants. Contaminants such as disinfection by-products. Therefore, photocatalysis technology is considered to be an ideal new technology for environmental management and a most promising means of controlling environmental pollution.

Read more: Staged Synthesis of High-purity Nano Bismuth Tungstate

sales@chinatungsten.com

sales@chinatungsten.com