Tungsten Oxide Quantum Dots Synthesis by Ultrasound Hydrothermal Method

- Details

- Category: Tungsten Information

- Published on Friday, 04 October 2019 18:20

- Written by meiwei

- Hits: 1506

Quantum dots (QDs) are a new kind of nano-fluorescent materials. Because of their unique electrical and optical properties, QDs have been widely used in physics, chemistry, biology and other fields. As a new fluorescent material.

Read more: Tungsten Oxide Quantum Dots Synthesis by Ultrasound Hydrothermal Method

Waste Tungsten Oxide Recycle and Treatment

- Details

- Category: Tungsten Information

- Published on Friday, 04 October 2019 18:14

- Written by meiwei

- Hits: 1516

At present, the existing processes for recovering and treating waste tungsten oxide to produce ammonium tungstate solution, ammonium paratungstate and ammonium metatungstate are all based on the chemical properties of all tungsten trioxide and blue tungsten oxide which are insoluble or slightly soluble in ammonia water and only soluble in caustic soda or soda ash. The process is to dissolve oxygen in normal pressure or pressure boiling with caustic soda (sodium hydroxide) solution or soda carbonate solution in advance. Tungsten carbide is prepared into sodium tungstate solution, or tungsten oxide is melted with sodium carbonate at high temperature, then tungsten is boiled and leached to form sodium tungstate solution.

Tungsten Oxide Hydrogen Sensor

- Details

- Category: Tungsten Information

- Published on Friday, 04 October 2019 16:56

- Written by meiwei

- Hits: 1400

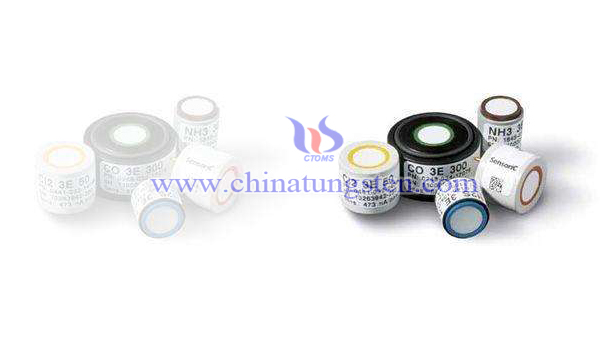

In industrial production, hydrogen, as a non-polluting green energy, has attracted wide attention. However, hydrogen is volatile, low ignition point, colorless and tasteless. It is a very dangerous flammable gas when it encounters open fire when its concentration in air is 4-75%. Therefore, the monitoring technology and research of gas sensitive materials for hydrogen play an important role in ensuring personal and property safety.

Porous Silicon Composite One-Dimensional Tungsten Oxide Nanostructured Gas Sensitive Materials

- Details

- Category: Tungsten Information

- Published on Friday, 04 October 2019 17:51

- Written by meiwei

- Hits: 1454

Nitrogen oxide (NOx), as a highly toxic gas, is the main source of acid rain and photochemical smog, which has posed a serious threat to human health and safety. Therefore, the detection of nitrogen oxides has become a research hotspot in recent years.

Tungsten Trioxide Hydrogen Sulfide Gas Sensor

- Details

- Category: Tungsten Information

- Published on Friday, 04 October 2019 16:50

- Written by meiwei

- Hits: 1491

Hydrogen sulfide is a colorless gas with the odor of rotten eggs. Its toxicity is very strong. Its permissible concentration in the air is 10 ppm. The upper and lower limits of explosion range from 4.3% to 46.0%. The harm of hydrogen sulfide gas to human body belongs to chemical nerve toxicity, stimulation and asphyxiation gas, which can destroy red blood cells and cause olfactory stimulation at 0.1 ppm. Therefore, how to quantitatively detect trace hydrogen sulfide gas in the air has become an urgent problem to be solved in relevant workplaces.

sales@chinatungsten.com

sales@chinatungsten.com