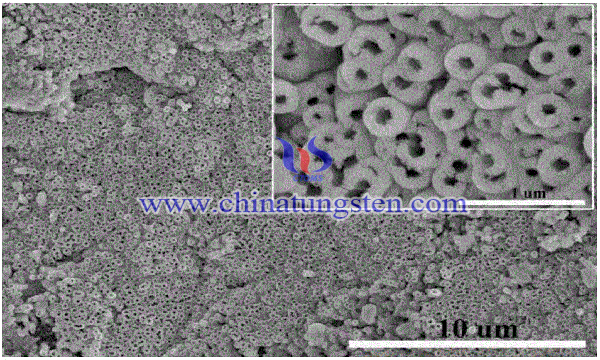

Nano Tungsten Disulfide Can Be Used to Produce Hydrogen from Seawater

- Details

- Category: Tungsten Information

- Published on Saturday, 05 October 2019 21:52

- Written by meiwei

- Hits: 1676

Although sunlight is a clean energy source, many problems hinder its widespread use. The most important is its intermittence, which is not always sunny, and sunny periods are not always highly correlated with electricity demand. In addition, if the electricity generated by solar energy cannot be used or stored immediately, it will be wasted. Therefore, there is a need for a practical way to store solar energy, which can be used when needed. These means can make people use solar energy and hydrogen energy more efficiently and further reduce their dependence on oil.

Read more: Nano Tungsten Disulfide Can Be Used to Produce Hydrogen from Seawater

Tungsten Oxide Photocatalyst Loaded with Titanium Dioxide and Copper Ions

- Details

- Category: Tungsten Information

- Published on Saturday, 05 October 2019 21:44

- Written by meiwei

- Hits: 1528

Titanium dioxide is known as a photocatalyst material, but it has little function in the absence of ultraviolet radiation. Therefore, Scientists prefer to study visible-light tungsten trioxide photocatalysts.

Read more: Tungsten Oxide Photocatalyst Loaded with Titanium Dioxide and Copper Ions

Tungsten Trioxide Separation from Waste SCR Denitrification Catalyst

- Details

- Category: Tungsten Information

- Published on Saturday, 05 October 2019 17:51

- Written by meiwei

- Hits: 1594

At present, most power plants in our country mainly use coal as fuel. The direct combustion of coal will produce a large number of nitrogen oxides which pollute the environment. At present, flue gas denitrification technology is widely used in developed countries to reduce the emission of nitrogen oxides, and the denitrification rate can reach more than 90%.

Read more: Tungsten Trioxide Separation from Waste SCR Denitrification Catalyst

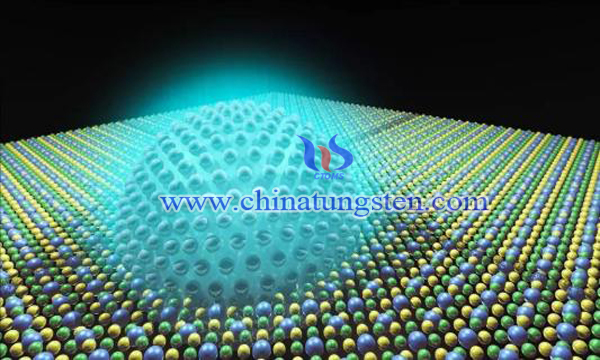

Tungsten Oxide Quantum Dots Preparation by Solvent Method

- Details

- Category: Tungsten Information

- Published on Saturday, 05 October 2019 21:38

- Written by meiwei

- Hits: 1594

Energy shortage and environmental deterioration have become the most important problems facing all countries in the world. The development of new functional materials will be an effective way to solve these problems. Because of its unique physical and chemical and electronic properties, tungsten oxide materials have good application prospects in the fields of color-changing window, photocatalysis, fuel cell, chemical sensor, environmental purification, solar energy conversion and other functions, and have become one of the hot topics in the current research of new materials.

Read more: Tungsten Oxide Quantum Dots Preparation by Solvent Method

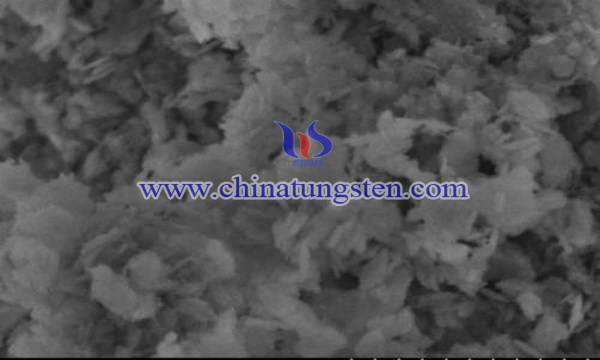

Tungsten Trioxide Nanosheets Mechanochemical Method

- Details

- Category: Tungsten Information

- Published on Saturday, 05 October 2019 17:16

- Written by meiwei

- Hits: 1536

Recently, some scholars have attempted to prepare tungsten trioxide nanosheets with high specific surface area, high crystallinity, high dispersibility and low cost by mechanochemical method. The main process is to prepare tungstic acid (WO3·H2O) nanosheets using tungstic acid-based organic or inorganic layered hybrid micro/nanobelts (tubes) as precursors, and remove the organic matter between the precursor layers by nitric acid oxidation. The reaction temperature is 15-50 ℃. The time is 5-120 H. The tungsten oxide nanosheets are prepared by heating them at a heating rate of 1-5 ℃/min to 250-600 ℃, then holding them for 1-5 h, and then cooling them to room temperature naturally. The specific operation is as follows:

Read more: Tungsten Trioxide Nanosheets Mechanochemical Method

sales@chinatungsten.com

sales@chinatungsten.com