Microwave Heating Ammonium Paratungstate to Prepare Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 June 2020 11:52

- Written by Yahong

- Hits: 1905

It is a new process to obtain tungsten trioxide by microwave heating ammonium paratungstate. The process requires a short calcination time (only 4min, while the traditional method takes about 2h), and the prepared yellow WO3 powder product is of good quality so that it is worth applying in industry.

Read more: Microwave Heating Ammonium Paratungstate to Prepare Tungsten Trioxide

Wet Ammonium Paratungstate Preparing Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 June 2020 11:51

- Written by Yahong

- Hits: 1929

The researchers proposed a method for preparing tungsten trioxide by using wet ammonium paratungstate as raw material.

Read more: Wet Ammonium Paratungstate Preparing Tungsten Trioxide

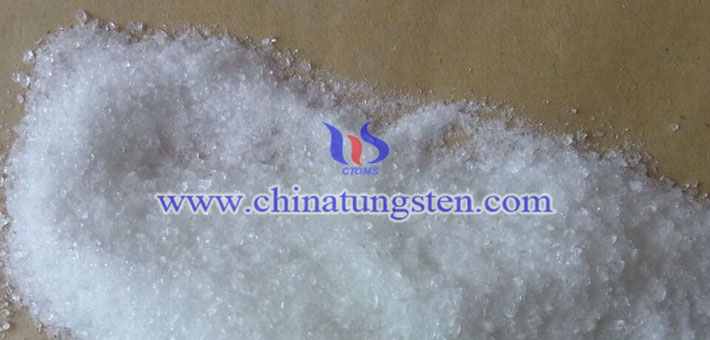

How to Prepare High Purity Ammonium Paratungstate?

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 June 2020 11:48

- Written by Yahong

- Hits: 2017

How to prepare high purity ammonium paratungstate? The researchers proposed an economical method for preparing high purity ammonium paratungstate with high yield and simple process.

Read more: How to Prepare High Purity Ammonium Paratungstate?

Thermal Decomposition Process of Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 June 2020 11:49

- Written by Yahong

- Hits: 1962

Thermal decomposition process of ammonium paratungstate has attracted much attention of researchers as it is an important raw material for preparing tungsten oxide (by calcining APT), and tungsten oxide is an important raw material for preparing tungsten powder by hydrogen reduction, and tungsten powder is an important raw material for preparing tungsten electrode by powder metallurgy.

Read more: Thermal Decomposition Process of Ammonium Paratungstate

Tungsten Heavy Alloy Shield

- Details

- Category: Tungsten Information

- Published on Friday, 05 June 2020 20:06

- Written by Yahong

- Hits: 1940

Tungsten heavy alloy shield is made with high tungsten content and low amounts of Ni, Fe or Ni, Cu. Some tungsten alloy shields are added Co, Mo or Cr, etc. The density of tungsten heavy alloy could be as high as 16.8-18.8g/cm3.

sales@chinatungsten.com

sales@chinatungsten.com