Tungsten Hexachloride Applied for Tungsten Carbide Composite Catalytic Material

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 June 2020 16:14

- Written by Yahong

- Hits: 1916

Tungsten hexachloride is an important tungsten source for producing tungsten carbide composite catalytic material with platinum-like catalytic properties. For example, some researchers used tungsten hexachloride as the source of tungsten, the stripped montmorillonite sheet as the carrier, and combined the chemical impregnation method with the in-situ reduction carbonization technology to prepare tungsten carbide composite catalytic material - a nanocomposite of tungsten carbide and montmorillonite.

Read more: Tungsten Hexachloride Applied for Tungsten Carbide Composite Catalytic Material

Tungsten Hexachloride Applied for Porous WO3 Film

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 June 2020 16:12

- Written by Yahong

- Hits: 2007

Tungsten hexachloride can be applied for preparing porous WO3 film. Wherein, porous WO3 film is a common gas-sensitive material with excellent gas-sensing performance and gasochromic performance. In addition, it is a typical electrochromic material, and is considered to be one of the most promising electrochromic materials. Tungsten hexachloride (WCl6) is a raw material for preparation of new material that can be used in the chemical industry for catalytic applications, as well as in the glass industry, mainly for the production of surface coatings. So, what is the connection between the porous WO3 film and tungsten hexachloride?

Read more: Tungsten Hexachloride Applied for Porous WO3 Film

Intermediates from Decomposition of Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Sunday, 14 June 2020 00:46

- Written by yuntao

- Hits: 1876

Ammonium paratungstate (APT) is a white crystalline salt with the chemical formula (NH4)10(H2W12O42)·4H2O. It is considered as the most important raw material for the tungsten industry. The majority of tungsten-based catalysts are derived from the reduction of APT.

Read more: Intermediates from Decomposition of Ammonium Paratungstate

Tungsten Hexachloride Applied for Preparing Ultrafine Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Tuesday, 16 June 2020 16:11

- Written by Yahong

- Hits: 1907

Generally, hydrogen is used to reduce tungsten hexachloride to produce ultrafine tungsten powder. And this method is also known as tungsten hexachloride hydrogen reduction method to prepare ultrafine tungsten powder. It includes preparation of WCl6 and reduction of WCl6 into tungsten powder.

Read more: Tungsten Hexachloride Applied for Preparing Ultrafine Tungsten Powder

Nanoscale Tungsten Carbide by Plasma Synthesis of Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Sunday, 14 June 2020 00:36

- Written by yuntao

- Hits: 1900

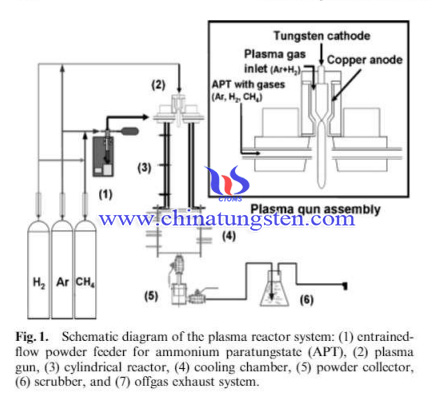

Tungsten carbide (WC) has excellent properties of high hardness, high strength, high rigidity, good wear resistance, and thermal conductivity. It has wide application files of tools in the metalworking, drilling, and mining industries under severe conditions of high-pressure, high-temperature, and corrosive environment. These mechanical properties is affected by the composition and microstructural parameters including the grain size. It is known that reduction of WC gives a significant improvement in the mechanical properties of the consolidated compacts. So, an efficient and useful production method of nanoscale WC powder is necessary.

Read more: Nanoscale Tungsten Carbide by Plasma Synthesis of Ammonium Paratungstate

More Articles...

- Crystalline Ammonium Tungsten Bronze by Thermal Decomposition of Ammonium Paratungstate (APT)

- Preparation of WC Based Cemented Carbide by Using Ammonium Paratungstate as Binder

- Production Method of Nanostructured W–Co Powder by Thermal Reduction of Cobalt Doped Ammonium Paratungstate

- N−Doped WO3 Photocatalyst by Thermal Decomposition of Ammonium Paratungstate (APT)

sales@chinatungsten.com

sales@chinatungsten.com