New Structural Yellow Tungsten Oxide Photocatalytic Material

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2020 16:30

- Written by Yahong

- Hits: 1947

Researchers have prepared a new structural yellow tungsten oxide photocatalytic material by hydrothermal method in a high-pressure reactor. Wherein, the obtained yellow tungsten oxide (WO3) has characteristics of large specific surface area, a size in the micro-nano range, good structural stability, and a narrow band gap. So, it is convenient for applications of photocatalytic degradation of organic dyes. Moreover, preparation of yellow tungsten oxide by hydrothermal method has advantages of easy availability of raw materials, mild conditions and simple operation.

Read more: New Structural Yellow Tungsten Oxide Photocatalytic Material

Defective Yellow Tungsten Oxide Nanoparticle

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2020 16:28

- Written by Yahong

- Hits: 1916

Defective yellow tungsten oxide nanoparticle can be used to convert solar energy into thermal energy, thereby developing a new type of photothermal conversion material.

Tungsten Alloy Collimator Applied for Anger Camera

- Details

- Category: Tungsten Information

- Published on Thursday, 18 June 2020 14:35

- Written by Yahong

- Hits: 1982

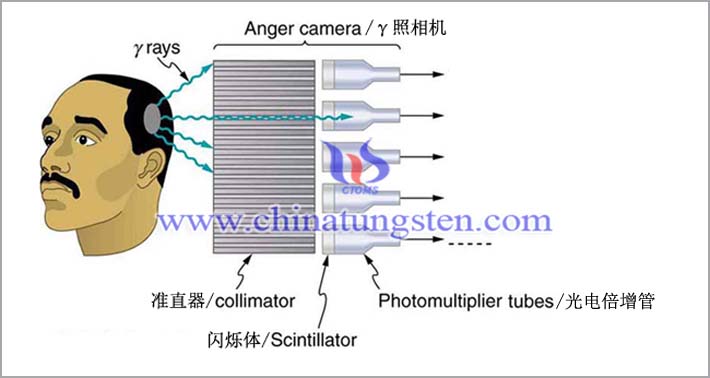

Tungsten alloy collimator is used in an anger camera for collimation and absorption of gamma rays. And therefore, it improves imaging quality and protects patients. Anger camera, which is more often known as gamma camera or γ-camera, is a device used to image gamma radiation emitting radioisotopes.

Read more: Tungsten Alloy Collimator Applied for Anger Camera

Yellow Tungsten Oxide Applied for Photocatalytic Coating

- Details

- Category: Tungsten Information

- Published on Friday, 19 June 2020 16:26

- Written by Yahong

- Hits: 1895

Yellow tungsten oxide, or tungsten trioxide (WO3), may be widely applied for producing photocatalytic coating. Tungsten trioxide has band gap between 2.4-28eV, and has good absorption of visible light. Also, it is very stable in aqueous solution. So, it is regarded as a potential photocatalytic material for visible light response. Therefore, WO3 photocatalyst with excellent visible light photocatalytic performance may be used to produce photocatalytic coating.

Read more: Yellow Tungsten Oxide Applied for Photocatalytic Coating

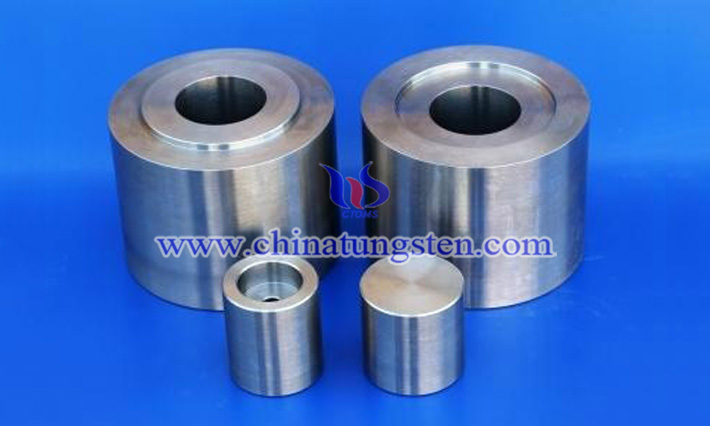

Tungsten Alloy X-ray Collimator

- Details

- Category: Tungsten Information

- Published on Thursday, 18 June 2020 14:34

- Written by Yahong

- Hits: 1897

Tungsten alloy X-ray collimator is a highprecision collimator for X-ray detectors, which absorbs scattered radiation and thus helps ensure an extremely high image quality. W (tungsten alloy) is better suited for this task than any other element in the periodic table as it has high density and excellent X-ray absorption capability.

sales@chinatungsten.com

sales@chinatungsten.com