Quality Control of Tungsten Wire for Glass Heating

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 19:03

- Written by Zhenghua

- Hits: 151

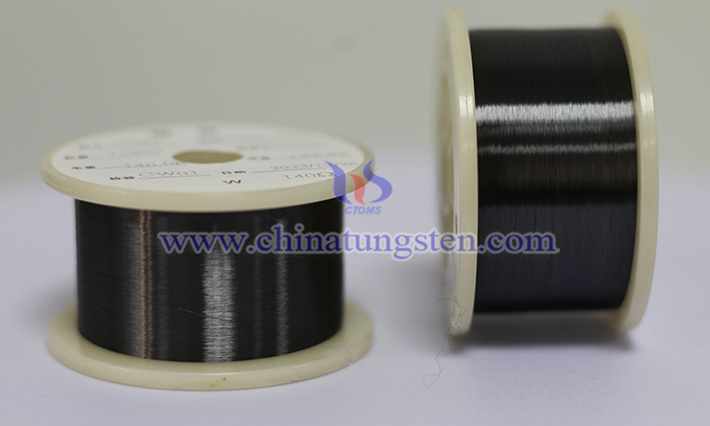

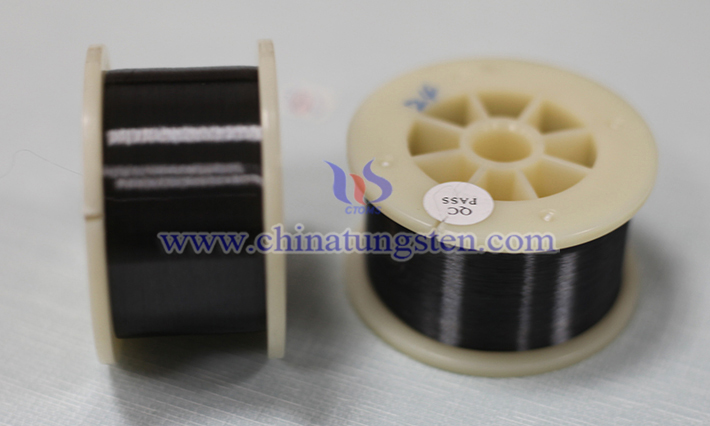

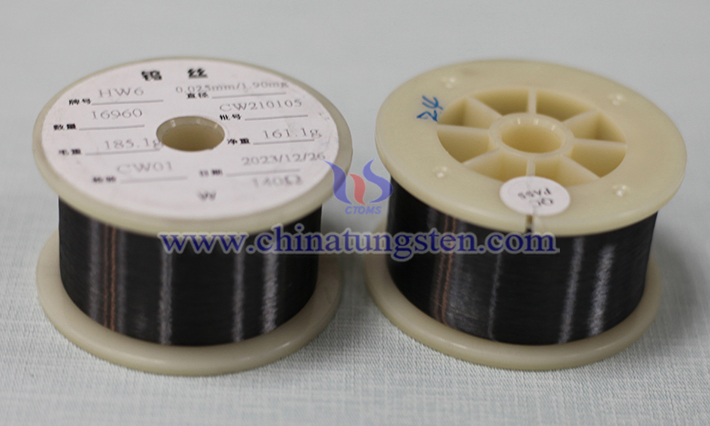

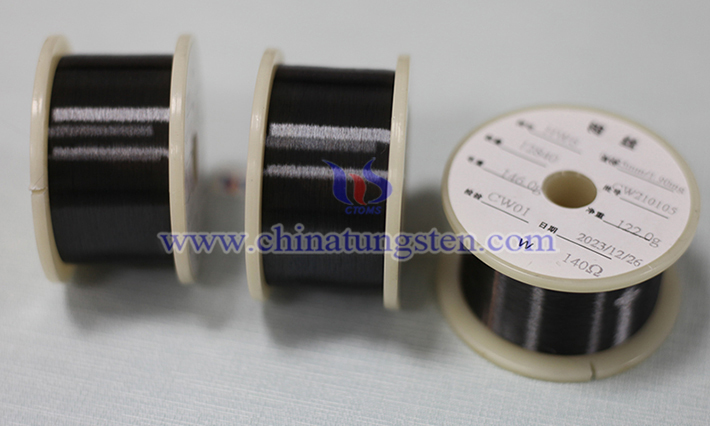

The quality control of tungsten wire for glass heating involves multiple key links such as raw materials, production, and testing to ensure its stable performance, high temperature resistance and long service life.

Read more: Quality Control of Tungsten Wire for Glass Heating

The Use Environment of Tungsten Wire for Glass Heating

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 18:58

- Written by Zhenghua

- Hits: 145

Tungsten wire is often used in glass heating environments due to its high melting point (about 3422℃), high strength and good conductivity, especially in high temperature processes such as glass melting, molding or annealing. The following are the key characteristics and requirements of tungsten wire in the use environment of glass heating:

Read more: The Use Environment of Tungsten Wire for Glass Heating

How to Use Tungsten Wire to Heat Glass?

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 18:51

- Written by Zhenghua

- Hits: 162

Heating glass with tungsten wire requires careful operation to ensure safety and effectiveness. The following are specific steps and precautions:

1. Select a Suitable Tungsten Wire:

Detection of Tungsten Wire for Glass Heating

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 18:53

- Written by Zhenghua

- Hits: 162

The detection of tungsten wire for glass heating mainly involves its physical properties, chemical stability and electrical characteristics to ensure its safety and reliability during high-temperature heating. The following are the key points and methods of detection:

Production Steps of Tungsten Wire for Glass Heating

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 18:49

- Written by Zhenghua

- Hits: 138

Tungsten wire is an ideal choice for glass heating applications due to its high melting point and high temperature resistance. The following is a brief overview of the main production steps for producing tungsten wire for glass heating:

Read more: Production Steps of Tungsten Wire for Glass Heating

sales@chinatungsten.com

sales@chinatungsten.com