Ammonium Metatungstate Catalyzing Epimerization of Glucose to Produce Mannose

- Details

- Category: Ammonium Metatungstate

- Published on Tuesday, 24 January 2017 17:20

- Written by chunyan

- Hits: 2409

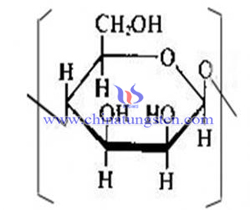

Mannose is a kind of monosaccharide, and also a kind of hexose, wherein the most typical is the D - mannose, which exists in cells of the plants, and has very important role in the pharmaceutical, food and feed industry, as well as in the life science and other fields, it can be used in the synthesis of L – ribose and the precursor compound of shikimic acid, the medicine and chemical raw materials of mannitol, trifluoro mannose ect..

Mannose is a kind of monosaccharide, and also a kind of hexose, wherein the most typical is the D - mannose, which exists in cells of the plants, and has very important role in the pharmaceutical, food and feed industry, as well as in the life science and other fields, it can be used in the synthesis of L – ribose and the precursor compound of shikimic acid, the medicine and chemical raw materials of mannitol, trifluoro mannose ect..

In addition to molybdate, the catalyst of epimerization of glucose can be replaced by the complexing body which is formed by metal ions (such as Ni2+, Cu2+, Co2+ and Cd2+) and nitrogen organic matters. However, research shows that the effect of metal complexing body as the catalyst of epimerization is not so good, therefore it is not applicable to industry. W-base catalyst has been found with an excellent effect on the catalysis of the epimerization of glucose as raw material to manufacture mannose, besides, this process has the advantages of sample operation, high yield and low cost.

The true example:

A. Preparation of W2C/AC catalyst

1. Prepare the ammonium metatungstate (AMT) solution with the concentration of 0.4 g/ml;

2. Dip the carrier of activated carbon (AC) in ammonium metatungstate solution, then transfer the reactant into to the oven after dipped for drying for 12 hours under temperature of 120°C, to get the catalyst precursor;

3. get a temperature programmed carbon thermal response of the catalyst precursor under hydrogen atmosphere, with the reaction process of: 1.0g of precursor is heated in the quartz reaction tube from room temperature to 400°C, and then heat the tube to 800°C at the heating rate of 1°C/min and keep the temperature value for 1 hour for carbonization, wherein the hydrogen flow rate is 60ml/min, and finally get the W2C/AC catalyst with tungsten loaded of 30wt%.

B. Production of mannose by epimerization

1. Prepare glucose solution at a certain proportion of water and glucose, stir until the glucose completely dissolving in water with heating, but the particle burning phenomenon caused by the too high temperature should be avoided;

2. Transfer the feed solution and AMT catalyst into the semi-continuous reactor or high pressure reaction kettle at the reaction temperature, and finally convert the glucose to mannose by controlling a certain reaction conditions, the mannose yield on the ammonium metatungstate catalyst can reach to 38.9%.

| AMT Supplier: Chinatungsten Online ammonium-metatungstate.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com