The Basics of a Game of Darts(II)

- Details

- Category: Tungsten Information

- Published on Sunday, 15 February 2015 18:23

- Written by xsh

- Hits: 536

Matches usually start from 501 in competition darts but other common starts are 301, 401, 701, and even 1001. Sometimes darts matches are played where a “double” is required to start each “Leg” of the match. However, the most common form of play is “straight start” which means that players/teams can begin to score points immediately with the first darts game thrown. Both teams start on the agreed starting number and the object is to score down to zero as quickly as possible. The value of the different sectors of the dartboard can be seen in Fig 1. above. Each section or “leg” of the match must be finished with a “double”, this means the outer scoring ring. For example as one approaches the end of a “leg” a player or team may have 40 points left to score. This means Double 20 is required and to end the “Leg” a dart must be thrown into the “double” section of the “20” sector. Should the thrower miss “double” 20 and hit (for example) a single 1, the the thrower would require 39 to win the “leg” where a single 7 then “double” 16 could be an option. Another example could be the player or team require 51 points. Then there would be several alternatives to end the “leg”. The usual route would be either a single 11 and then “double” 20, or perhaps a single 19 and then “double” 16. The first player or team to hit the required “double” wins the “leg”. A new leg is then started and the procedure repeated until one of the players or teams has won the required number of “legs” to win darts game.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Basics of a Game of Darts(I)

- Details

- Category: Tungsten Information

- Published on Sunday, 15 February 2015 18:22

- Written by xsh

- Hits: 455

A game of darts always starts, and ends, with a handshake.

A game of darts can be played in played in several forms. The most common forms are:- One player against another which is known as “Singles” or teams of two players per team which is known as “Doubles” or “Pairs”. A game of darts is played over an agreed number of sections which are known as “legs”. The number of “legs” in a game is always an odd number usually 1, 3, 5, or 7 “legs”. Matches are played as (for example) “Best of 5 “legs”. This means that the first player or team to win 3 “legs” win the match.

Players throw alternately in “Singles” matches. In “Doubles” or “Pairs” matches each “Pair” throws alternately with each player in the respective “Pair” also throwing alternately. A “Throw” consists of “3” darts. If a player completes the “Leg” or the match in less than three darts the remaining dart or darts gameare not thrown.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Care Dart?

- Details

- Category: Tungsten Information

- Published on Sunday, 15 February 2015 18:17

- Written by xsh

- Hits: 469

Dart caring need to keep the needle tip dart degrees.

First, dart beneath the blanket has a certain area of the pad or other cushioning material, so when racing game, dart needle or damage the floor.

Second, the target ring long metal darts in use carom, may loosen, just to nail nailed to move one position.

Third, the paper target darts have various reasons such as climate, there will be some cracks are normal and do not affect the results.

Fourth, sisal darts, in the humid climate, use hair dryer to dry the target surface, to maintain a certain dry to prevent mildew. If mildew occurs. Hair brush can be useful to the stain, wipe clean with alcohol, then blow dry, do not affect the results.

Fifth, keep the needle tip dart degrees, pull the dart, the barb, which will damage the target surface, the impact dartboard life otherwise.

Six, dart bar, dart feathers, dart needle is wearing parts, consumables, dart caring for use when replacing the need to press models, specifications with purchase.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Official Dartboard Setup

- Details

- Category: Tungsten Information

- Published on Sunday, 15 February 2015 18:20

- Written by xsh

- Hits: 479

It should not rush into buying a set of darts. The weight and shape of darts varies enormously, as do the shapes of the flights.

We recommend that you try as many different types of darts and flights as possible before making a purchase. After a while you will soon become aware that each different type of dart behaves differently when YOU throw it. Take your time, find a set that you feel comfortable with before you buy.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

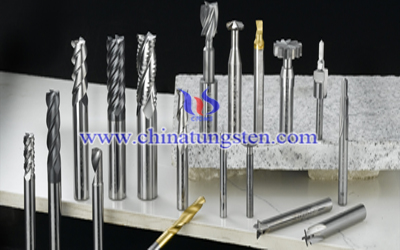

Tungsten Carbide Cutting Tool Edge Defects (B)

- Details

- Category: Tungsten Information

- Published on Sunday, 15 February 2015 09:09

- Written by yewq

- Hits: 473

the life of tungsten carbide cutting tools. Cutting edge surface usually produces the following defects: flash, micro-gap edge region, the residual stress and the blade surface area cobalt leaching.

3. Residual Stress

tungsten carbide cutting tools due to its texture, structure and manufacturing process and other factors, in the manufacturing and sharpening process, the remaining energy will be unevenly accumulate on the surface or inside of the tool, the performance of the residual stress and stress concentration. Residual stress and stress concentration exists, the tool in the cutting process is more sensitive to stress and thermal stress, prone to fatigue cracking and chipping, leading to decreased tool life or damage.

4. Cobalt leaching

In the process of grinding of tungsten carbide cutting tools, grinding fluid not only can reduce the grinding temperature, but also serve to improve the quality of grinding and grinding efficiency effects, and therefore widely used in the processing. China Tianjin University graduate student Zhang good strong analyze the mechanism of cemented tungsten carbide cobalt leaching, and the use of oleic acid, triethanolamine and borax as a cutting fluid additives. Experimental results show that this method can suppress the leaching of cobalt tungsten carbide elements, thereby increasing tool life and reduce the cutting fluid on the human body. Grinding tungsten carbide grinding fluid when it is possible to make use of tungsten carbide cobalt leaching. Cobalt cemented tungsten carbide as binder, it will greatly reduce the leaching tungsten carbide cutting resistance to mechanical impact and service life.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com