Decomposition of Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Friday, 27 February 2015 17:30

- Written by zsq

- Hits: 383

The possibility of mechanochemical decomposition of ammonium paratungstate (APT) has been studied, and compared with thermal decomposition method. For this purpose, APT powders were milled using a planetary ball mill up to 36 h and under air atmosphere. For thermal decomposition, APT powders were heated for 30 minutes at 300 and 450 °C in air atmosphere. X-ray diffraction (XRD), differential scanning calorimeter (DSC), and thermo gravimetric analyzer (TGA) were used to study the decomposition progress, and products. The XRD results showed that APT completely decomposed to WO3 by thermal decomposition, while the final product of mechanochemical decomposition was WO3 (H2O)0.5. According to DSC and TGA results, during thermal decomposition, ammonia and water released in four steps, and leaved WO3. By mechanochemical decomposition crystal water and ammonia liberated from APT structure, but structural water of APT remained. In both methods, an X-ray amorphous phase was the intermediate product of APT decomposition.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Processing Tungsten Carbide Nanopowder from APT

- Details

- Category: Tungsten Information

- Published on Friday, 27 February 2015 17:27

- Written by zsq

- Hits: 443

Thermal plasma process has been applied to the synthesis of nanosized tungsten carbide powder with ammonium paratungstate (APT) as the precursor. The reduction and carburization of vaporized APT produced nanosized tungsten carbide (WC1−x) powder, which sometimes contained a small amount of W2C phase. The effects of reactant gas composition, plasma torch power, the flow rate of plasma gas, and the addition of secondary plasma gas (H2) on the product composition and particle size were investigated. The produced tungsten carbide (WC1−x) powder was <20 nm in particle size. The synthesized powders were also subjected to a hydrogen heat treatment to fully carburize the WC1−x and W2C phases to the WC phase as well as to remove excess carbon. Finally, WC powder of particle size <100 nm was obtained.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

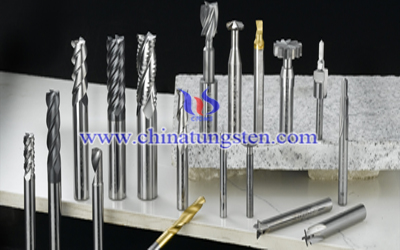

Tungsten Carbide Cutting Tools Diffusion Wear

- Details

- Category: Tungsten Information

- Published on Friday, 27 February 2015 09:12

- Written by yewq

- Hits: 447

After decades of development, the hardness of tungsten carbide cutting tools has reached 89 ~ 93HRA, at a high temperature of 1000 ℃ still has good red hardness, durability is several times its high speed steel cutting tools. tungsten carbide cutting tools material is WC, TiC, TaC, NbC, VC and other refractory metal tungsten carbides and prepared by powder metallurgy from iron group metals as a binder. Compared with the high-speed steel, it has high hardness, wear resistance and red hardness; compared with super hard material, it has a higher toughness. Because of tungsten carbide cutting tools has a good overall performance, so in the tools industry has been widely used.

However, under certain circumstances, tungsten carbide cutting tools diffusion wear occurs. Diffusion wear occurs at high temperature effects. tungsten carbide at the time of cutting temperature 800 ~ 900 ℃, W and C atoms will diffuse to chip in, chip in Ti and Al atoms will diffuse into the tool, after mutual displacement between atoms, it will reduce the tools interatomic bonding strength and wear resistance and the formation of diffusion wear. When cutting titanium, due to the high temperature of the cutting area, and the surface is always in contact with each other just cutting out a fresh surface, chip, before the workpiece and tools flank greater chemical activity, so the tools material and titanium tungsten carbide element alloy contact surfaces will spread to the other side to each other, and cause diffusion wear, changing the chemical composition of both the direct impact on its performance.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Preparing Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Friday, 27 February 2015 17:21

- Written by zsq

- Hits: 453

Violet tungsten oxide was prepared with pure ammonium paratungstate in argon gas. Tungsten powder was obtained from violet tungsten oxide through deoxidation in hydrogen gas (rate of purity: 99.99%, dew point: –40 °C), and tungsten powder was oxidized in the air. Tungsten oxide was reduced to tungsten powder in hydrogen gas. The samples were characterized with the laser particle size distribution measuring instrument and the electron probe scan instrument. The results show that submicron tungsten powder can be obtained through circulatory oxidation twice and reduction three times. The percentage of the particle size distribution of submicron spherical tungsten powder is 95.73% between 0.1 μm and 1.0 μm, and its BET is 1.082 m2/g.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Oxidation Wear

- Details

- Category: Tungsten Information

- Published on Friday, 27 February 2015 09:08

- Written by yewq

- Hits: 464

A refractory metal tungsten carbide cutting tools hard metal compound and a binder made by powder metallurgy method, its hardness (HRA) is 89 to 94, much higher than the high-speed steel; at 540 ℃ hardness (HRA) 82 to 87, and the hardness of high-speed steel normal temperature (HRA83 ~ 86) fairly, but also has good chemical stability, heat resistance advantages. tools materials currently used for a lot of variety though, the new tools materials are also emerging, but still very popular tungsten carbide cutting tools material kind.

When cutting titanium, tungsten carbide cutting tools cutting when the temperature reaches 700 ~ 800 ℃, tungsten carbide materials WC, TiC, and Co compounds and plays the role of oxygen in the air, forming a lower hardness and strength oxide film. As air enters the cutting area is not easy, it is easy to form an oxide film on the flank position after tungsten carbide cutting tools. When cutting the workpiece surface by the oxide, chilled layer and hard impurity continuous friction points on the oxide film, resulting in oxidation of flank wear, also called boundary wear. When a large amount of wear and tear, will form oxidation wear grooves. After tungsten carbide cutting tools oxidation wear mainly as tools and vice flank flank have emerged oxidation wear phenomenon. And this phenomenon is more pronounced in high-speed cutting.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com