Separating Molybdenum in Production Process of Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Thursday, 12 February 2015 11:38

- Written by zsq

- Hits: 447

Separation of tungsten and molybdenum in production process of ammonium paratungstate is important working procedure ,but this is always one of difficult technical problems .General flows of various ammonium paratungstate technologies and basic nature of molybdenum were summarized .Moreover advantages and disadvantages of each separation method for tungsten and molybdenum in production process of ammonium paratungstate were systemarically analyzed .A nalysis results indicated that there many advantages , such as short process folw small tungsten loss, good molybdenum eliminating effect, simplicity of operation,low environmental pollution and economy feasibility to eliminate molybdenum by ion-exchange method . It is precisely because of these advantages, ion-exchange method to eliminate molybdenum has a good industrial application prospect.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ultrasonic Effect Crystallization of Ammonium Paratungstate from Aqueous Solution

- Details

- Category: Tungsten Information

- Published on Thursday, 12 February 2015 11:33

- Written by zsq

- Hits: 513

By evaporating and neutralizing of two ammonium tungstate with different density ,crystals of ammonium paratungstate (NH1)10W12O11·Nh2o(n=11,7,5)were prepared with ultrasonic .UsingXRD,DTG and granularity analysis, the crystalline form was confirmed and researched .The results proved that the effect of ultrasonic on ammonium tungstate was in evidence .The crystalline forms were the same with ultrasonic and without ultrasonic, but impure apexes on the XRD patterns were less and value of d/A more tallied with literature with ultrasonic . Distributing of crystalline granularity became narrower and the crystal was more homogeneous. Ultrasonic shortened the formation time nucleus of crystal .

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

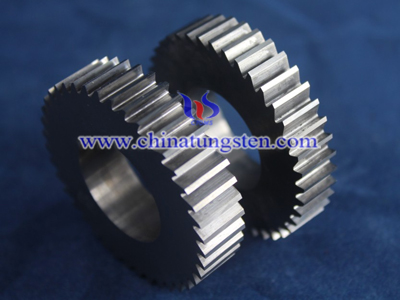

Tungsten Carbide Cutting Tools Gradient Processing

- Details

- Category: Tungsten Information

- Published on Thursday, 12 February 2015 10:19

- Written by yewq

- Hits: 463

A refractory metal tungsten carbide hard metal compound and a binder made by powder metallurgy method, its hardness (HRA) is 89 to 94, much higher than the high-speed steel; at 540 ℃ hardness (HRA) 82 to 87, and the hardness of high-speed steel normal temperature (HRA83 ~ 86) fairly, but also has good chemical stability, heat resistance advantages. Tool materials currently used for a lot of variety though, the new tool materials are also emerging, but still very popular tungsten carbide tool material kind.

In order to prevent the material as a result of crack propagation due to the failure, and is favorable for obtaining a high-performance tungsten carbide cutting tools material may gradient processing, the surface area of the coated substrate formed lack toughness cubic tungsten carbides and carbonitrides of region, this region is higher than the binder content of the nominal binder content of the coating substrate; when a crack is formed in the coating extended over the area, because of their toughness, crack propagation can absorb the energy, it is possible to effectively tungsten carbide cutting tools to prevent cracks internal expansion, improve the performance of tungsten carbide cutting tools.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Removal of Ammonia from APT Crystal Mother Liquor

- Details

- Category: Tungsten Information

- Published on Thursday, 12 February 2015 11:30

- Written by zsq

- Hits: 511

Ammonia in APT crystal mother liquor was removed by adding sodium tungstate with sodium hydroxide and magnesium salts. The results show that the content of ammonia in the treated solution can be removed down to 0.042g/L up to 98.8 % removal rate. The resultant sodium tungstate solution was diluted 10 times befote prepared as ion exchange feed solution., the content of ammonia in the raffinate is less than 0.0005%, which can meet China national discharge standard .

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool Edge Passivation Case

- Details

- Category: Tungsten Information

- Published on Thursday, 12 February 2015 10:17

- Written by yewq

- Hits: 554

The extremely sharp and smooth enough neat cutting edge machining to have a specific, smooth shape, and edge rounding mostly waterfall edge, this process is called edge passivation. tungsten carbide cutting tool edge passivation change the contours of the cutting edge and morphology, but also to improve the microstructure of the blade surface area, thereby affecting the cutting process, tool performance and workpiece quality. tungsten carbide cutting tool edge passivation impact, affecting mainly the following aspects: the distribution of cutting temperature, the size distribution of cutting force, stress and strain, and chip formation and chip flow, deformation region of the workpiece, the workpiece surface integrity (residual stress), the machined surface roughness, surface hardening process and tool wear resistance.

Edge passivation tungsten carbide cutting tools for working efficiency has an important role in the following cases generally require the tool edge passivation:

1. The new sharpening of tungsten carbide cutting tools or regrinding of tungsten carbide cutting tools.

2. Prior to the tungsten carbide coating.

3. When the impact of heavy-duty cutting or cutting edge tungsten carbide cutting tools needed to passivation.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com