Microemulsion Method Producing Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 15:12

- Written by xiaoshan

- Hits: 420

Currently, producing tungsten trioxide methods are many, such as hydrothermal method, solid method, liquid phase method, sol-gel method and microemulsion method. Microemulsion method is a two incompatible liquid reaction with surfactant to form a uniform emulsion, precipitated solid phase from the emulsion, so you can make the nucleation, growth, coalescence, agglomeration and other processes confined to a tiny spherical droplets inside, thereby forming spherical particles, to avoid further agglomeration between particles. Producing tungsten trioxide by microemulsion method the process is as follows:

1. Weigh 0.200gCTAB added 8ml cyclohexane and 12ml n-butanol with fully stir.

2. The mixed solution was divided into 2 parts of divide into solution A and solution B, solution A was added in 6ml1: 1 hydrochloric acid solution, phacoemulsification 15min.

3. B was added sodium tungstate solution 3ml, phacoemulsification 15min.

4. Under magnetic stirring, hydrochloric acid was added dropwise to the emulsion in the sodium tungstate solution, until the solution was no longer yellow far deeper.

5. Stop stirring, aging 16h, the supernatant liquid was removed, dried over by anhydrous ethanol and distilled water were washed several times, then centrifuged, and then into an oven at 100 ℃ drying to obtain a precursor.

6. The precursor was placed in a muffle furnace burning three hours, to give a yellow powder.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Crucible for Sapphire Use (2)

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 15:12

- Written by Yahong

- Hits: 438

Tungsten crucibles can applied in sapphire growing, serving as one of its core components, under normal circumstances, tungsten crucible size for this purpose will be relatively large, height is about: 300-500mm, outer diameter is about: 300-500mm. Sapphire growth furnace is for growing the LED chip.

Because of good high temperature resistance performance of tungsten crucible, so when it is in high temperature conditions, tungsten crucible is still able to maintain its stable performance, physical and chemical reactions do not occur with the single crystal, and the single crystal purity is guaranteed. Therefore, it makes tungsten crucible more popular than other materials for sapphire single crystal growth furnace.

Sapphire growth furnace aims to foster sapphire single crystal by Kyropoulos method. This method is: heating the raw material (alumina) of tungsten crucible to its melting point of 2050 degrees or more, and then gradually reduce the melting temperature, so it can crystallize into specific granules. The growth furnace is constructed in a closed mold with special insulation shell, cover and a heater.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

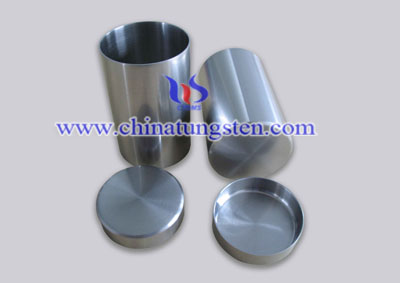

Tungsten Crucible Cover

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 14:34

- Written by Yahong

- Hits: 435

Tungsten crucible is made of tungsten crucible cover, tungsten crucible body and tungsten crucible base part (also known as tray). Because tungsten crucible has characteristic of high temperature resistance, low coefficient of expansion, etc., so it can be used as a main carrier in sapphire single crystal growth furnace. Tungsten crucible cover’s density is about 18.3 g / cm³, and its purity can reach 99.95% above. In sapphire growth furnace, tungsten crucible cover, as an insulator assembly, whose most important role is: cut off and reflect furnace heat. Tungsten crucible cover is closely combined with tungsten crucible body, which constitutes a confined space; you need control the confined space properly in order to produce high quality sapphire crystal. In addition, the tungsten crucible cover require higher purity, accuracy size also required and the surface should be smooth, these benefits can improve the quality of pulling sapphire crystal.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Using Scr Denitration Catalyst to Recover Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 15:09

- Written by xiaoshan

- Hits: 471

Tungsten trioxide and partial ammonium recovered from SCR denitration catalyst not only can reduce the emission of pollutants but also can take full advantage of residue, so this method gets widespread attention. Using SCR denitration catalyst to recover tungsten trioxide and ammonium methods are as follows:

1. Crushing and sieving SCR denitration catalyst to produce catalyst powder, and then mixed it with sodium carbonate evenly.

2. Putting mixed powder into furnace fired becomes sinter.

3. After one hour heat preservation then crushing and sieving into sinter powder. Pour the warm water to make the NA2WO4 and NAVO3 of sintered powder fully dissolved, after filtered and abandoned precipitate to get Na2WO4 and NaVO3 mixed solution.

4. After adjusting the PH value to 6.5 to 7.5, ammonium bicarbonate or ammonium chloride solution was added to precipitate ammonium metavanadate after filtered and washed by dilute bicarbonate solution for 2-3 times, then washed with 30% ethanol for 1-2 times, after drying to obtain metavanadate products.

5. The Na2WO4 of remaining solution was been converted into ammonium paratungstate, the remaining solution was evaporated to obtain crystals of ammonium paratungstate, and then calcined to obtain tungsten trioxide.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Cutting Speed for Milling

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 14:18

- Written by lucy

- Hits: 391

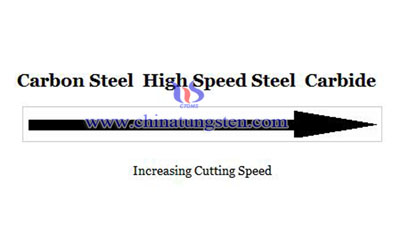

The cutting speed of the tungsten carbide cutting tool is the surface speed, which also refers to the speed at the milling cutters’ outside edge during its rotation. Specially ,the three directly related factors including, surface speed, surface footage, and surface area. The two wheels ones could be a proper example to explain, since one of its wheel is three feet in diameter and the other wheel which is one foot in diameter, roll each wheel one complete turn.

As the hardness of the cutting tool material makes a great effort to the suggested cutting speed, the tungsten carbide cutting tool has relatively harder cutting tool material, it presents faster cutting speed, whereas the softer the cutting tool material the slower the recommended cutting speed will be.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com