Tungsten Carbide Button TPA Mould Design

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 16:54

- Written by Cristina

- Hits: 417

Tungsten carbide button density is an important factor which affects tungsten carbide button quality. Apart from choosing proper pressing method, the size of material forming zone is very important.

If the forming zone is too low, the upper punch can not reach to the metal powder, and the lower punch can not reach the top layer which will cause the high pressure of the lower layer thus the density is uneven. And also the size of finished product will be too small.

If the forming zone is too high, both the upper punch and lower punch will not have enough power to press the middle layer. As a result the density in the neutral layer is lower than the other part. The punch needs to go deep inside the mould which will cause air block in the mould; the metal powder will stick to the punch and will cause damage. Also the mould will be overloaded; size of tungsten carbide button will be too large.

Only when the forming zone height is proper, the pressure on neutral layer from upper and lower punch is even, tungsten carbide button will be high density and quality.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button Nano Crystallization

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 16:53

- Written by Cristina

- Hits: 387

Tungsten carbide button is used in the coal cutter drilling tools, mine machinery tools and road maintenance tools. It is also widely applied for rock tools, mining tools for use in quarrying, mining, tunneling, and civil constructions.

Requirement of tungsten carbide button in rock drill is super high. The hardness should be high enough to increase its wear resistance; also the tenacity should be able to resist cracking. Nano crystallization can enhance its hardness and wear resistance. Research shows that under the same amount of binder, if the tungsten carbide grain size is less than 1um, tungsten carbide button hardness and tenacity improve a lot.

As the tungsten carbide grain size getting smaller, the properties of tungsten carbide button arise. Some researchers applied nano materials to tungsten carbide button sintering process, and it shows the sintering temperature falls down. Tungsten carbide button hardness, wear resistance, tenacity also improve a lot. Thus its service life extended and cut the producing cost.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide End Mill Coatings

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 14:35

- Written by lucy

- Hits: 443

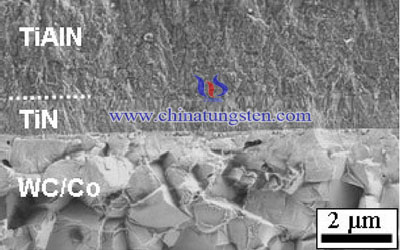

It is known that a right tool coating has a large influence for the tungsten carbide end mill in terms of cutting speed, tool life and surface finish situation.

Polycrystalline diamond is an exceptionally hard coating used on cutters which must withstand high abrasive wear. A PCD coated tool may last up to 100 times longer than an uncoated tool. However the coating cannot be used at temperatures above 600 degrees C, or on ferrous metals. Tools for machining aluminium are sometimes given a coating of TiAlN. Aluminum is a relatively sticky metal, and can weld itself to the teeth of tools, causing them to appear blunt. However it tends not to stick to TiAlN, allowing the tool to be used for much longer in aluminum.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button Shape Optimization

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 16:49

- Written by Cristina

- Hits: 409

Tungsten carbide button bits applied in rock drills have different shapes: hemispherical button, conical button, parabolic button and wedge button.

As the long hole drilling being widely applied than before, the requirement for tungsten carbide button quality applied in related equipments also enhances. Hemispherical button and conical button are the most widely applied in industry. During the application process, it can be observed that regular tungsten carbide hemispherical button can be easily passivating. Tungsten carbide conical button due to its wiry bit, can be cracking under big crash and super hard rock. Thus button profile can affect its properties in a certain degree.

Researchers invented a kind of tungsten carbide button which can resist blunt. This kind of button combines the shape of hemispherical button and conical button. It turns out that this kind of tungsten carbide button is of higher hardness and wear resistance, also drill velocity is faster.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool’s Workholding Devices

- Details

- Category: Tungsten Information

- Published on Monday, 15 June 2015 14:35

- Written by lucy

- Hits: 367

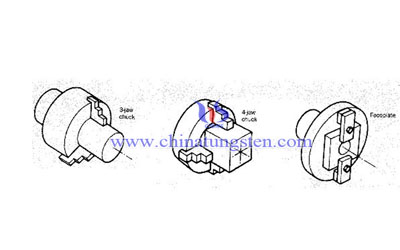

There are several most commonly used workholding devices for tungsten carbide cutting tool in nowadays’ lathe boring processes. It comprises into three-jaw chuck, four-jaw chuck and collet, as well as faceplate.

Since the three-jaw chuck is automatically centered, it is an ideal choice for holding round or hex workpieces. On latest model, if the condition is great, the runout faces limitation can be quite low , while traditionally it is usually not less than 0.025-0.075 mm. For the four-jaw chuck, it is recommended to apply in irregular shapes holding or round or hex holding to extremely low runout in time spent indicating and clamping each piece, in both cases as its independent action on each jaw. The face plate is also used for irregular shapes. Although collets’ price are higher, it perfectly combine self-centering chucking with low runout.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com