Iridium-Tungsten Oxide Composite Using APT as Precursor for Electrochemical Water Splitting

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 April 2021 19:21

- Written by yuntao

- Hits: 1823

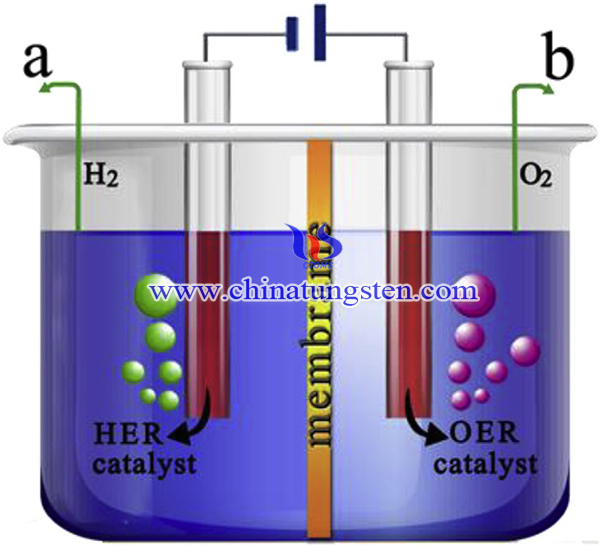

Hydrogen energy is a renewable clean energy that has been believed to be promising substitute to current energy source of fossil fuels. Electrochemical water splitting is a feasible approach to produce hydrogen gas in which hydrogen evolution reaction (HER) and oxygen evolution reaction (OER) taking place at cathode and anode electrodes respectively.

Preparation of Ce-W/Ti Catalyst with APT for Mercury Oxidation Application

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 April 2021 18:34

- Written by yuntao

- Hits: 1713

Mercury, serving as a persistent, toxic, bioaccumulative heavy metal, can be transported globally in the atmosphere, therefore mercury pollution is an important public health and environmental concern. Annual mercury emissions of China increased from 147 t in 1978 to 530 t in 2014, in which the contribution rate of coal field was 34%–50%.

Read more: Preparation of Ce-W/Ti Catalyst with APT for Mercury Oxidation Application

Synthesis of WO3 Thin Films with Ammonium Paratungstate for PEC Applications

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 April 2021 03:16

- Written by yuntao

- Hits: 1759

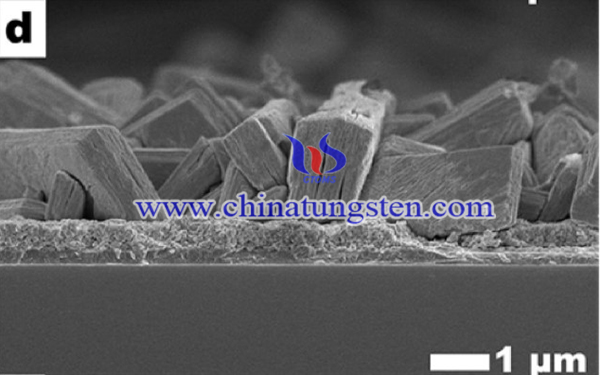

Photoelectrochemical (PEC) water splitting is considered as one of the cleanest, most efficient, and sustainable routes for the production of hydrogen (H2) and an ideal solution for future energy demands. Metal oxide semiconductors are known to be suitable materials for PEC water splitting as they are inexpensive and very stable in aqueous solutions. Moreover, reaching high PEC water splitting efficiency via metal oxide semiconductors is not easy.

Read more: Synthesis of WO3 Thin Films with Ammonium Paratungstate for PEC Applications

V2O5-WO3/Tio2 Catalyst for NO Reduction Using APT

- Details

- Category: Tungsten Information

- Published on Wednesday, 28 April 2021 03:33

- Written by yuntao

- Hits: 1747

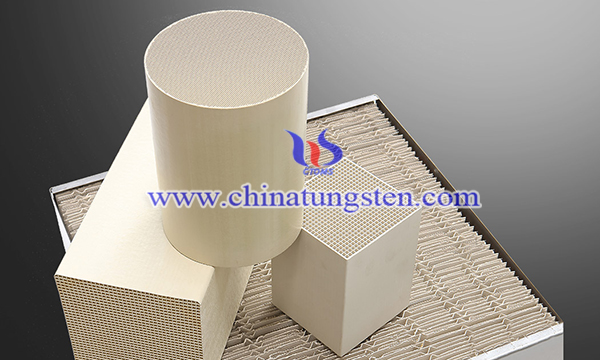

Fossil fuels as the major energy source had contributed to the rapid development of human society. At the same time, the green house gases such as CO2 and NH4 had brought the global warning, climate change, and many other issues. Combustion of most fuels, such as coal, oil, natural gas and biomass etc, results in emission of NOx, which is harmful to our environment creating acid rain and photochemical smog.

Read more: V2O5-WO3/Tio2 Catalyst for NO Reduction Using APT

Production Method of Molybdenum-Based Catalyst

- Details

- Category: Tungsten Information

- Published on Sunday, 25 April 2021 10:53

- Written by Hong

- Hits: 1674

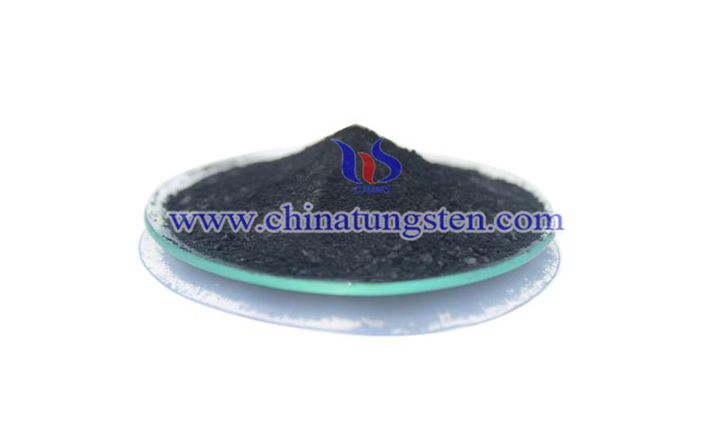

Currently the increasing haze weather in China has attracted high attention on environmental pollution. To control environmental pollution, it is necessary to control the emission of pollutants from motor vehicles. The key is to reduce the content of sulfur and make the desulfurization. At present, more than 95% of refineries in the world use molybdenum-based catalysts for desulfurization, which has the characteristic of high direct desulfurization activity and low hydrogen consumption. The common catalysts are cobalt-molybdenum catalysts and nickel-molybdenum catalysts.

The shape of molybdenum-based catalyst is flake or small ball with the size of 1.2~2.5mm, the color is dark blue, the density is 0.86~1.0g/cm3. It has high activity, good stability, high strength, long life and good sulfur resistance. The producer does not need to spend a lot of money to make deep desulfurization process, so the catalyst will have good economic prospects.

The production method of the catalyst is as follows:

1.0 First puts the required materials including active aluminum oxide powder, deionized water, nitric acid and extruding aid into the kneading machine, fully kneads them, and then extrudes them into the extruding machine.

2.0 Dry and calcine the above mentioned molding materials, the strip shaped alumina carrier is prepared.

3.0 Add cocatalyst, start to prepare Co Mo or Ni Mo aqueous solution according to the formula, and then impregnate or spray the added strip alumina.

4.0 Drain, dry and clacine the product mentioned in 3.0, and then Co Mo hydrodesulfurization catalyst is prepared..

The The catalyst is widely used and has various types, which plays an important role in the field. It is quite suitable for petrochemical and chemical industries. It is often used in petroleum hydrorefining, hydrodenitrogenation or the preparation of acrylic acid and crotonic acid. The catalyst is used in low-carbon industry and falls in green technology. The catalyst market in developing countries such as China will grow rapidly in future and occupy the main position in the catalyst market.

The The catalyst is widely used and has various types, which plays an important role in the field. It is quite suitable for petrochemical and chemical industries. It is often used in petroleum hydrorefining, hydrodenitrogenation or the preparation of acrylic acid and crotonic acid. The catalyst is used in low-carbon industry and falls in green technology. The catalyst market in developing countries such as China will grow rapidly in future and occupy the main position in the catalyst market.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com